Double-effect evaporator with automatic control function

A double-effect evaporation and effect evaporation technology, which is applied in the field of chemical equipment, can solve problems such as not being properly disposed of, and achieve the effect of reducing manpower input, reducing labor costs, and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

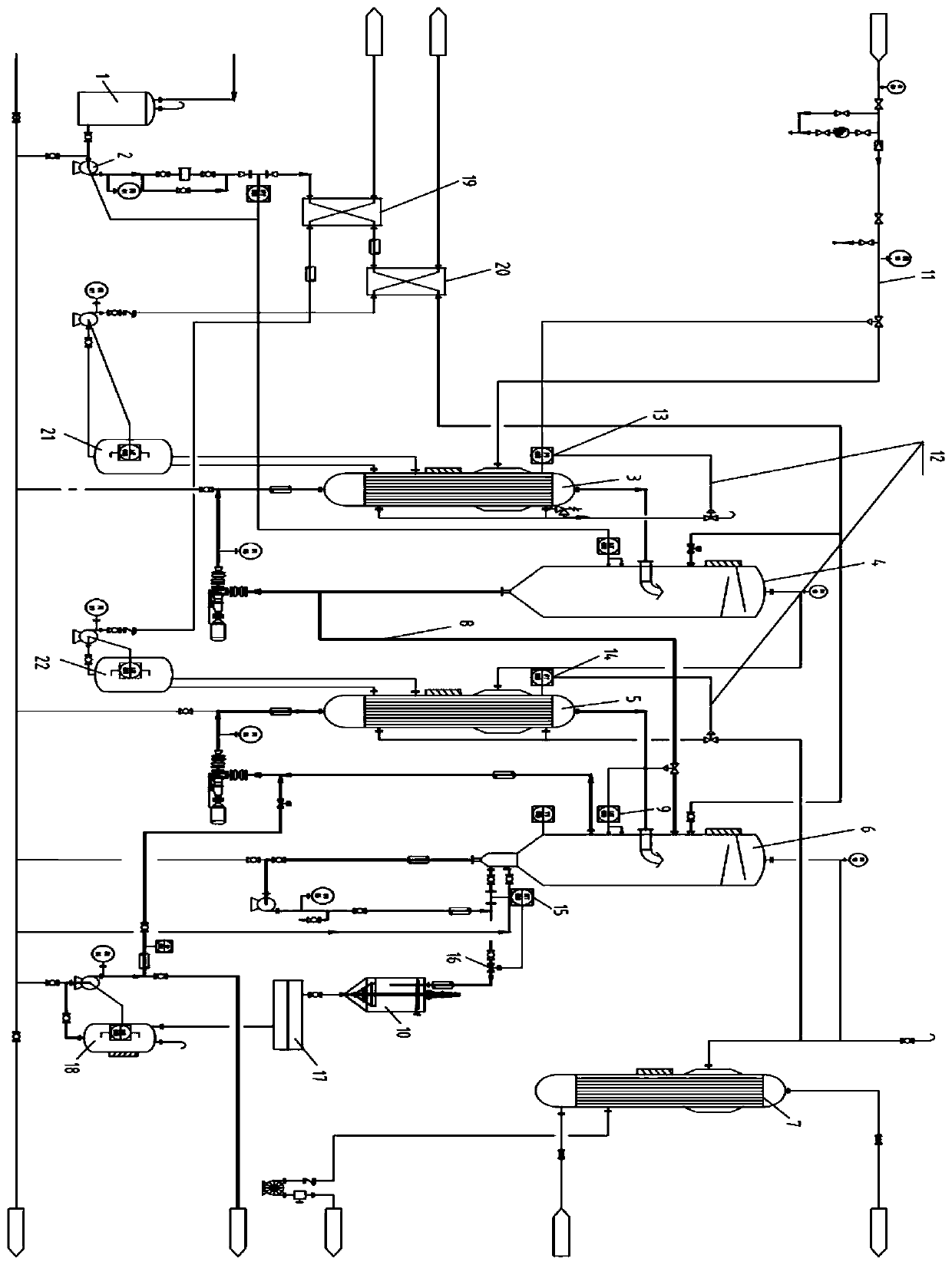

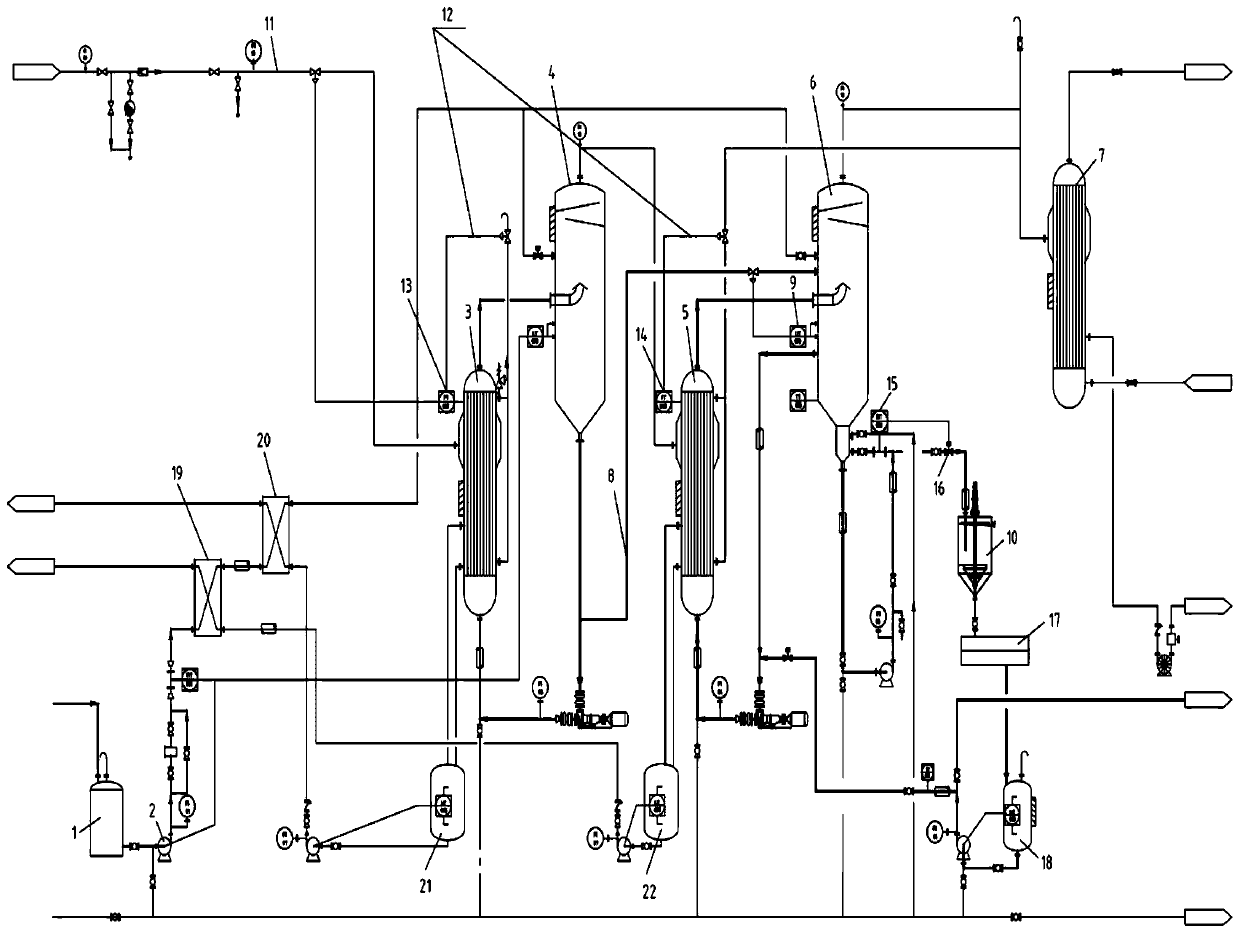

[0019] Such as figure 1 As shown, it is a double-effect evaporator with automatic control function of the present invention, including a raw material tank 1, a preheating device, a first-effect evaporator unit, and a second-effect evaporator unit connected sequentially through pipelines;

[0020] The preheating device includes a plate heat exchanger unit connected to the raw material tank 1 through the feed pump 2, and the raw material enters the plate heat exchanger unit from the raw material tank 1 through the feed pump 2 for preheating;

[0021] The one-effect evaporating unit includes a one-effect forced circulation heat exchanger 3, and the preheated raw material enters the one-effect forced circulation heat exchanger 3, and the one-effect forced circulation heat exchanger 3 transfers the raw material reaching the evaporation temperature to Delivered to the first-effect separator 4 connected thereto;

[0022] The two-effect evaporation unit includes a two-effect forced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com