Circulating type environmental protection machinery grille decontamination machine

A circulating and decontamination machine technology, which is applied in the chemical industry, can solve the problems of using heat energy, a large amount, and that the adsorbent cannot be recycled, so as to save energy, avoid waste, and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

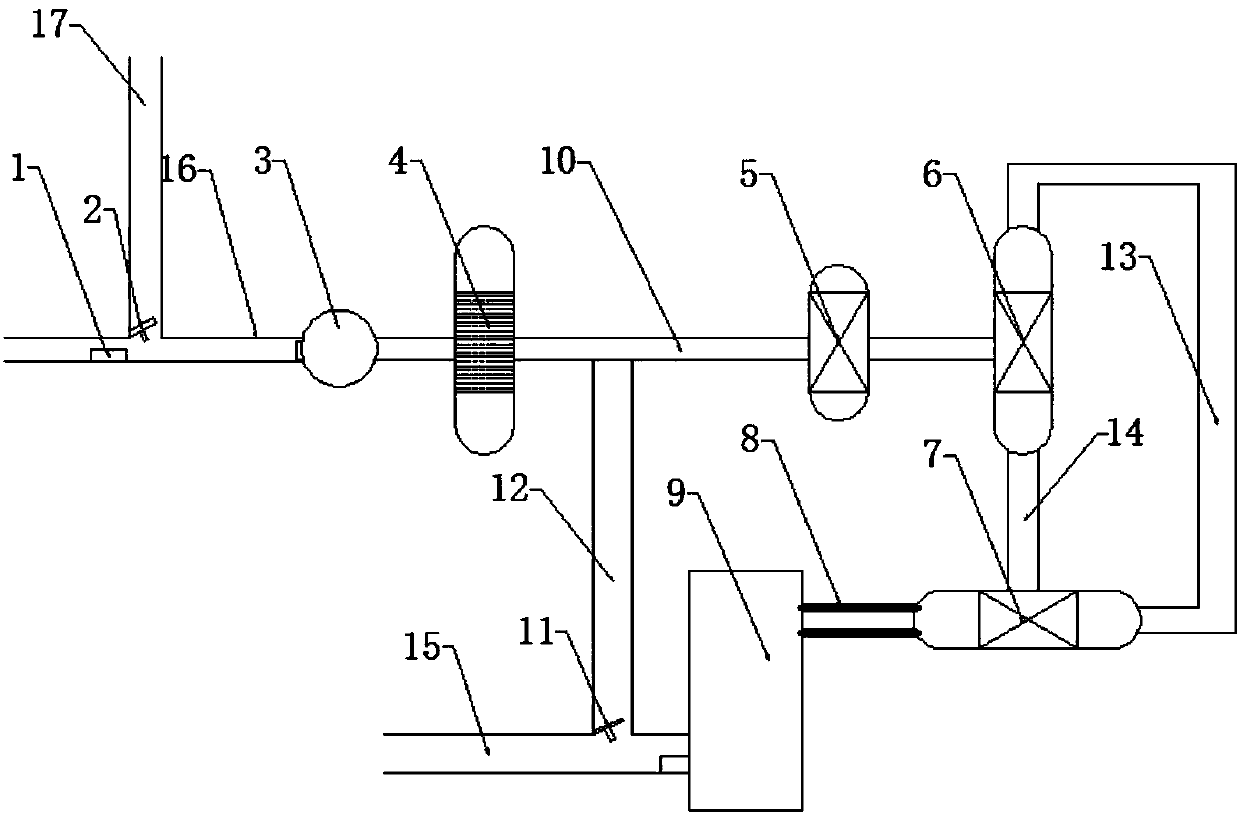

[0014] Such as figure 1 As shown, a circulating environmental protection mechanical grid decontamination machine of the present invention includes a VOCs detection controller 1, a suction fan 3, a filter screen 4, a plasma purification pipeline 8, a gas transmission pipeline 10, a gas return pipeline 12, and an adsorbent backflow Pipeline 13, adsorbent pipeline 14, exhaust pipeline 15 and intake pipeline 16, VOCs detection controller 1 is installed in the intake pipeline 16 and exhaust pipeline 15, one side of the intake pipeline 16 is connected to one end of the gas distribution pipeline 17 , the junction of the intake pipe 16 and the exhaust pipe 17 is provided with an intake valve 2, the suction fan 3 is installed on the gas transmission pipeline 10, the suction port of the suction fan 3 is close to the intake valve 2, and the air suction port of the suction fan 3 passes through the transmission Air pipeline 10 connects filter screen 4, and filter screen 4 is connected cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com