Whole spherical surface machining tool for differential mechanism

A differential and surface processing technology, which is applied in the field of differential global surface processing tooling, can solve the problems of difficult tooling manufacturing, such as the workpiece being easily crushed and damaged, and avoid being easily crushed, occupying small space, and difficult to manufacture. low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

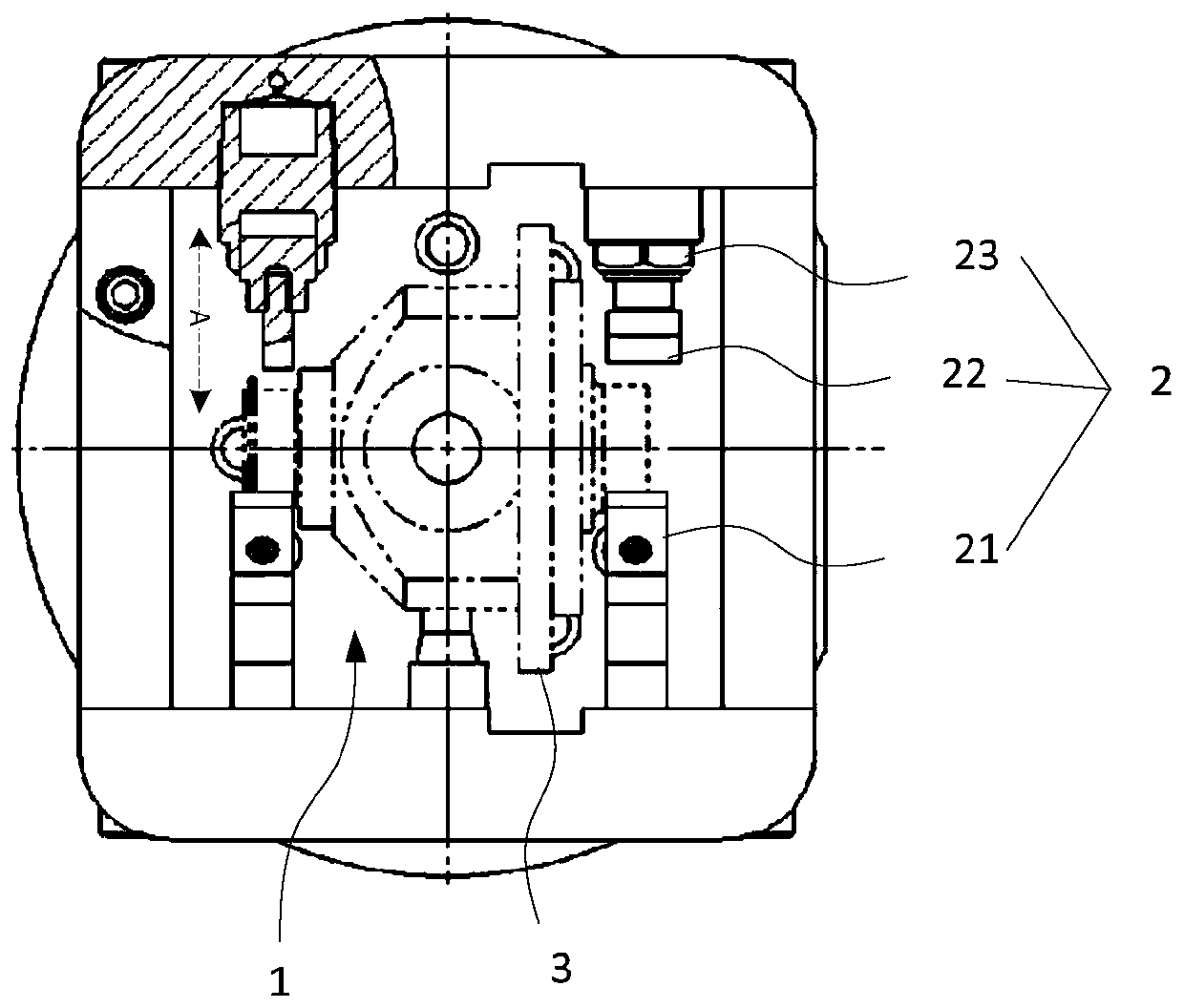

[0025] See figure 1 , the present embodiment provides a schematic top view of the differential spherical surface processing tooling of the present invention, as shown in the figure, the differential spherical surface processing tooling includes a station 1 that can accommodate a differential housing workpiece 3, On the station 1, there are two pressing mechanisms 2 for fixing the two ends of the differential housing workpiece 3 at intervals. The pressing mechanism 2 includes a first fixing splint 21, a second fixing splint 22 and a single-acting oil cylinder 23 , the first fixed splint 21 and the second fixed splint 22 are arranged oppositely at intervals, the second fixed splint 22 is connected to the single-acting oil cylinder 23, and the first fixed splint 21 and the single-acting oil cylinder 23 are respectively fixedly arranged on the station 1, When the differential case workpiece 3 is placed on the station 1, each pressing mechanism 2 moves synchronously through the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com