Ink supply system with planetary reduction cam device

A cam device and planetary deceleration technology, which is applied in the field of banknote printing and coinage, can solve the problems of large space occupation, high noise of mechanism operation, and many times of ink separation, so as to reduce equipment failure rate, improve work stability, and reduce ink transfer The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described by specific embodiments below.

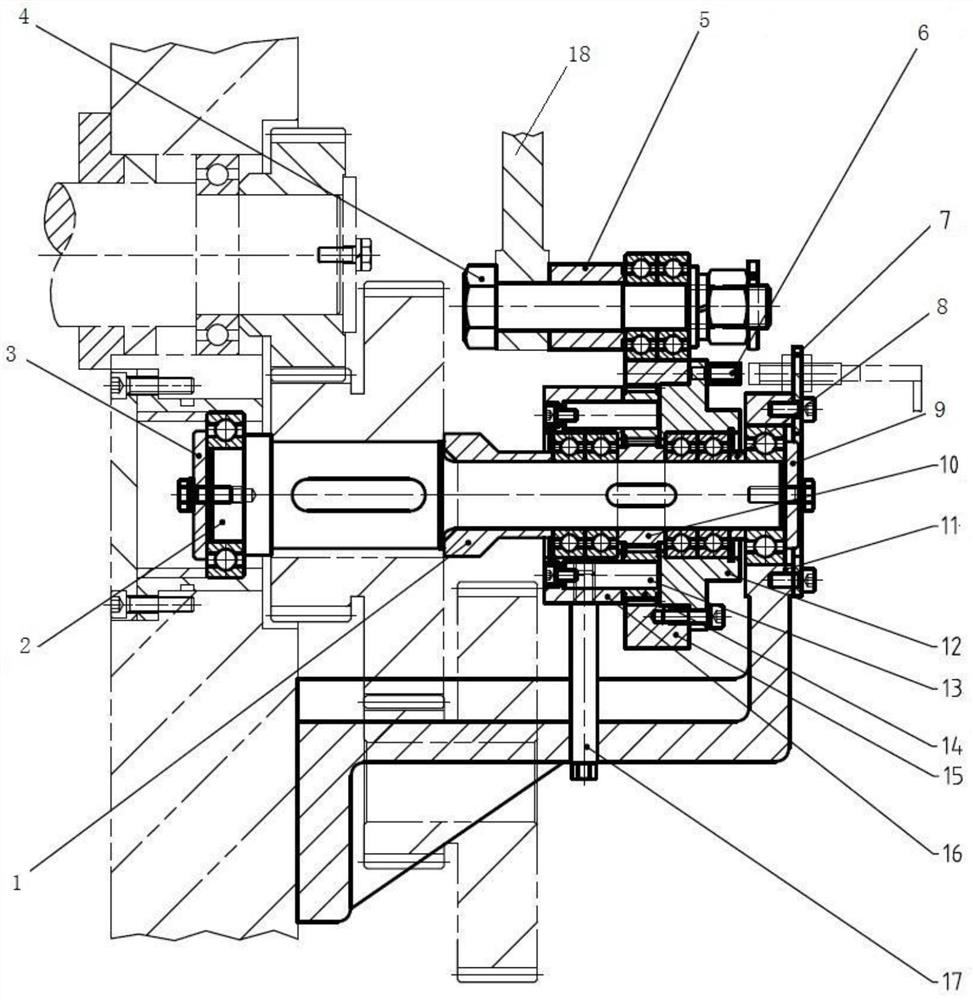

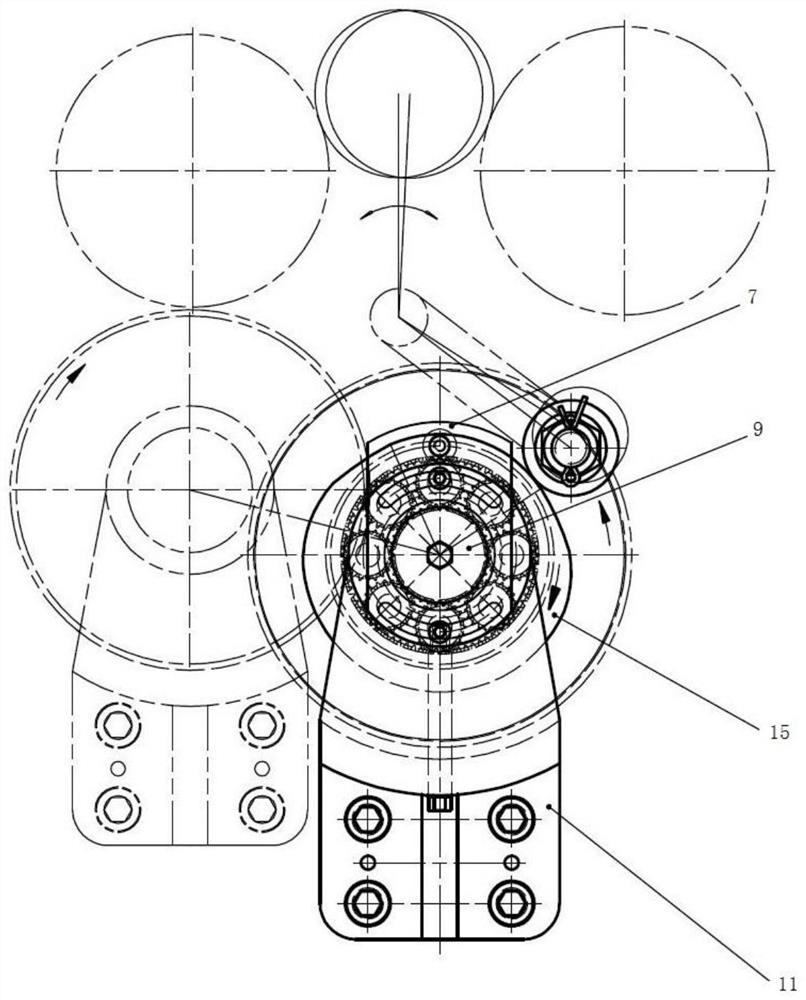

[0030] As attached figure 1 , Attached figure 2 As shown, the power source of the ink supply system with planetary reduction cam device is the main shaft 2 with double gears. One end of the main shaft 2 is in the machine body, and the other end is supported by the gear shaft bracket 11, and both ends of the main shaft 2 Equipped with shaft head covers 3 and 9. The power source of the main shaft 2 is the double gear adjacent to it. The sun gear 10 rotates synchronously with the main shaft 2 through a flat key. Preferably, the number of teeth of the sun gear 10 is 40, and the sun gear 10 drives the pinion 14 to rotate. The number of the pinions 14 is 2-10. Preferably, the pinion 14 The number of the pinion gear is 8, the number of teeth of the pinion gear 14 is 20, the pinion gear 14 is sleeved on the pinion shaft 13, and the pinion shaft 13 is fixed in the shaft sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com