Novel high-power herringbone gear compound planetary transmission speed reducer

A compound planetary, high-power technology, applied in the direction of gear transmission, transmission, mechanical equipment, etc., can solve the problems of not being able to meet the large transmission ratio and strength at the same time, difficult to process large-diameter bevel gears, and high transmission power of the reducer. Achieve the effect of novel transmission mode, good load equalization effect and large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

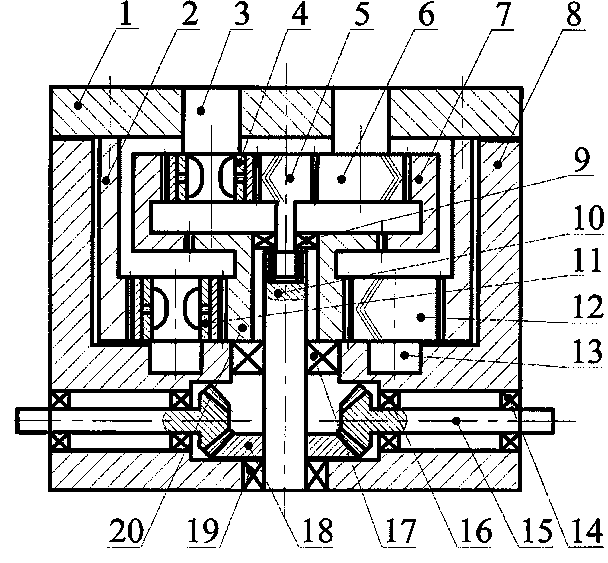

[0017] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with figure 1 The present invention will be specifically described. The new high-power herringbone compound planetary transmission reducer adopts a total of three-stage transmission, the first stage of multi-axis converging bevel gear orthogonal transmission, the second stage of differential gear train transmission, and the third stage of star gear train transmission; the motor transmits power through multiple (2 and more) first-stage input shafts (15) confluence and transfer to the first-stage bevel gear (18), and the first-stage input shafts (15) adopt input shaft front bearings (14) and input shaft rear bearings ( 16) Front and rear support respectively; the first stage bevel gear (18) transmits power to the second stage sun gear (5) through the spline shaft (10), and the spline shaft (10) adopts the spline shaft front bearing (19) Supported by the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com