Double-guide-groove steel cable drive type automatic unloading lifting carrying device

An automatic unloading and handling device technology, applied in transportation and packaging, lifting equipment in mines, elevators in buildings, etc., can solve the problem of large volume and occupied space, unsuitable for long-term application, high application and rental costs, etc. problem, to achieve the effect of small volume and occupied space, easy and precise position control, and stable and reliable transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

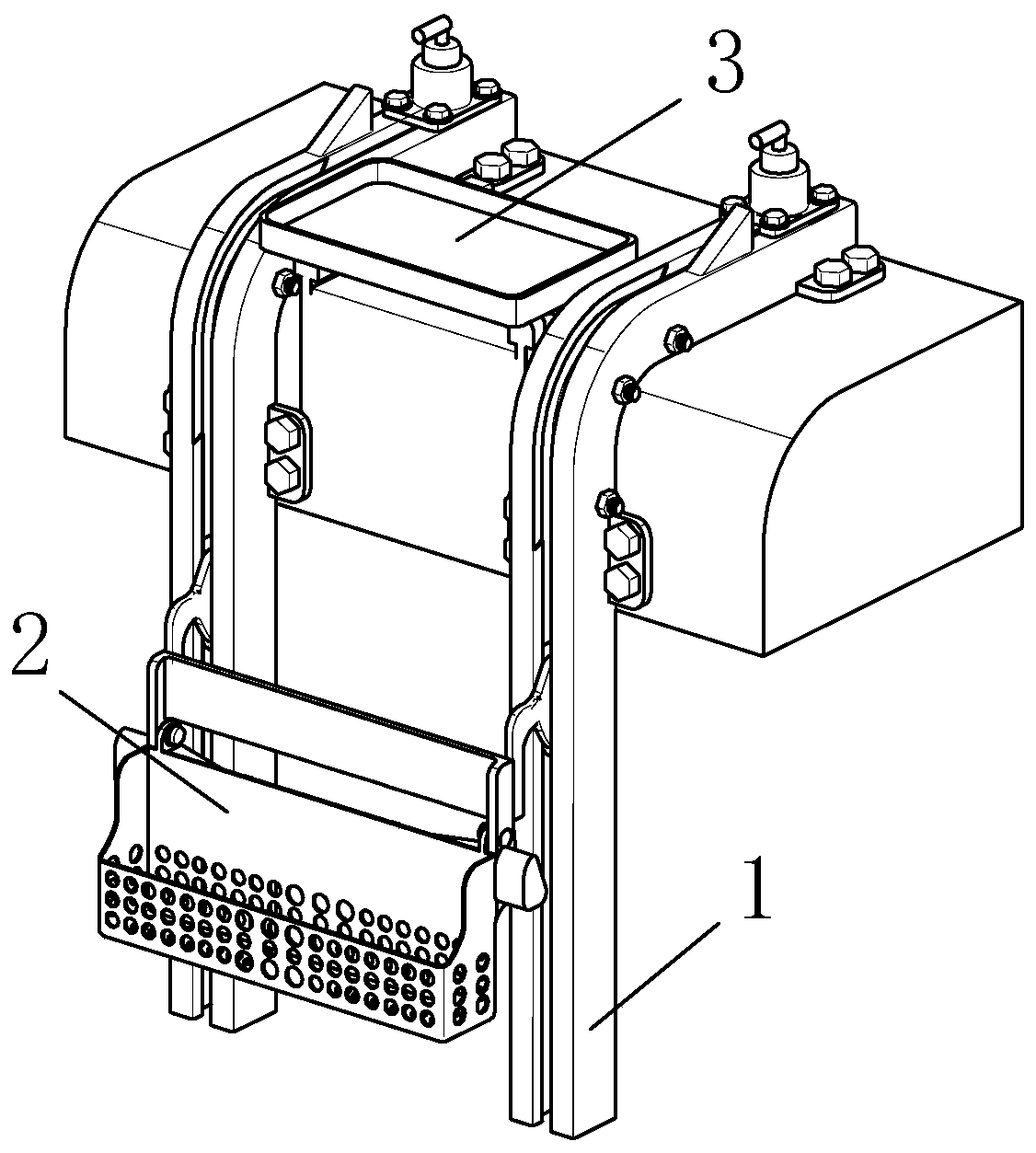

[0027] A double-guide cable-driven automatic unloading lifting and handling device, such as figure 1 As shown, it includes bracket assembly 1, transport bucket mechanism assembly 2 and ground transfer vehicle assembly 3;

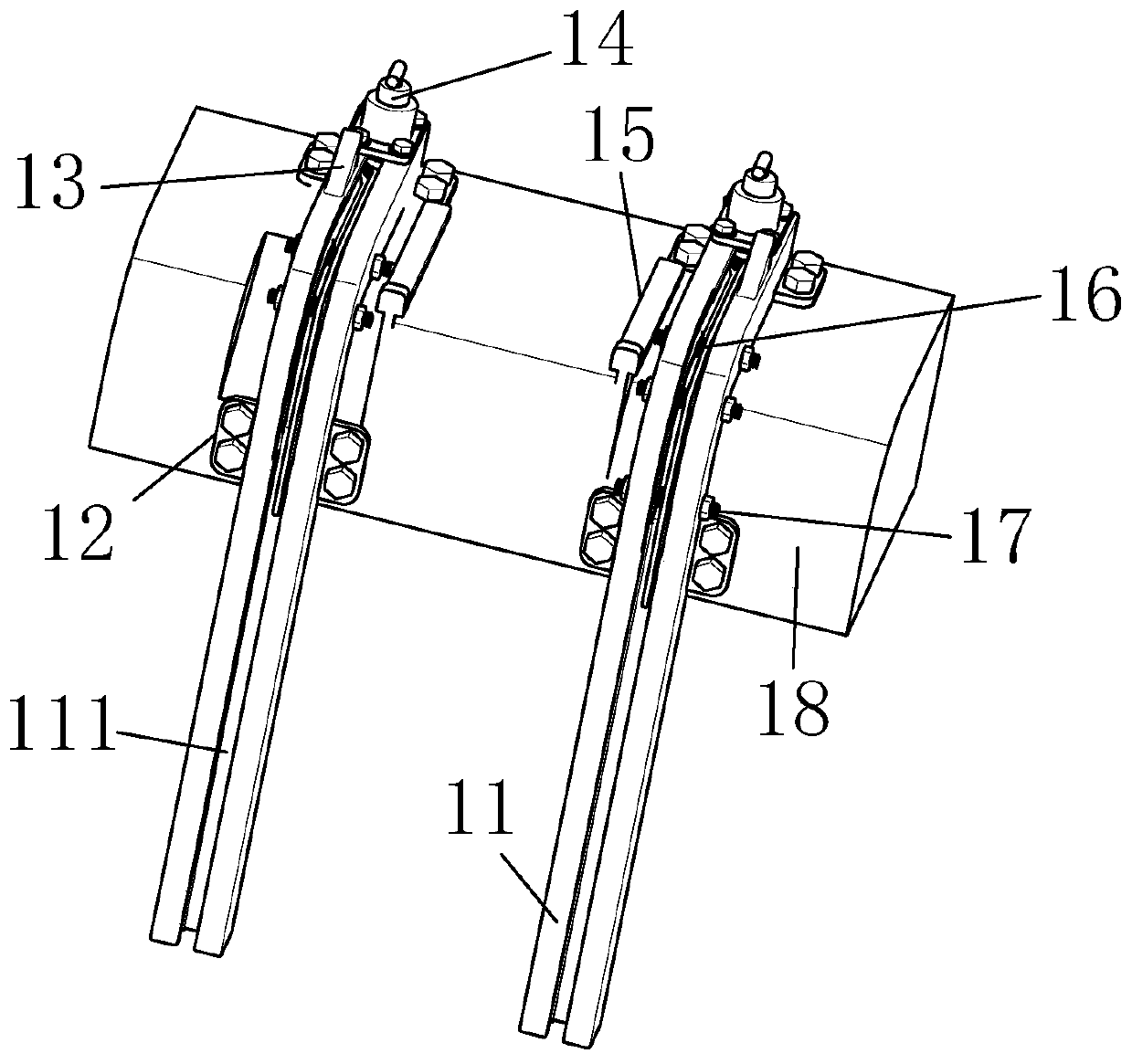

[0028] Such as figure 2 As shown, the bracket assembly 1 includes two side brackets 11, a guide groove 111, a bracket 12, a self-unloading guide block 13, a drive motor 14, a transport rail 15, a cable support roller 16, a roller installation shaft 17 and a base 18;

[0029] The two side brackets 11 are symmetrically arranged left and right, and the side brackets are in a curved arc structure. Each side bracket 11 includes a horizontal section, an arc section and a vertical section, and the horizontal section and the vertical section are integrally connected by an arc section. ; The middle part of the side bracket 11 is provided with a guide groove 111, the guide groove is used for the guide movement of the roller and the normal positioning of the groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com