Highway drainage system and novel expressway

A technology for highways and drainage systems, applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as high cost of repair projects, impact on driving safety, damage to highways, etc., to prevent roadbed soil from collapsing and control quality , the effect of low flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

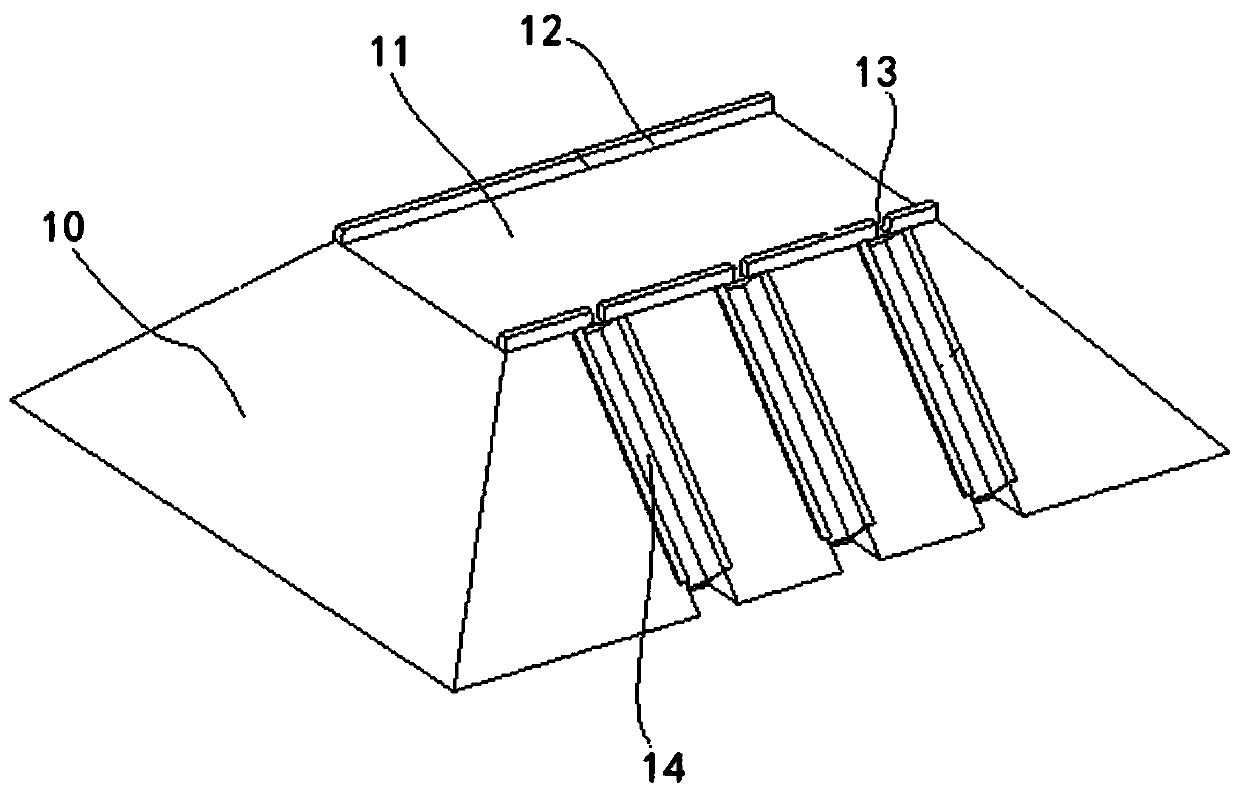

[0034] A kind of novel expressway of present embodiment, has such as image 3 The high-fill road section and cut-cut road section shown, the new expressway has a corresponding high-fill drainage system and cut-cut drainage system.

[0035] Among them, high-fill road sections such as image 3 As shown, there is a high-fill roadbed 10 and a high-fill road surface 11. The two sides of the high-fill road surface 11 are provided with water-retaining belts 12 extending along the length direction of the road near the edge. There is a drain 13 from the distance. Preferably, in this embodiment, the distance between adjacent water outlets is 20-25m.

[0036] As the biggest improvement of this embodiment, such as image 3 As shown, the new expressway subverts the design concept of the traditional high fill drainage system, and a side ditch 30 is set on the outside of the water retaining belt, and the side ditch 30 is used for centralized collection of rainwater on the high fill road. ...

Embodiment 2

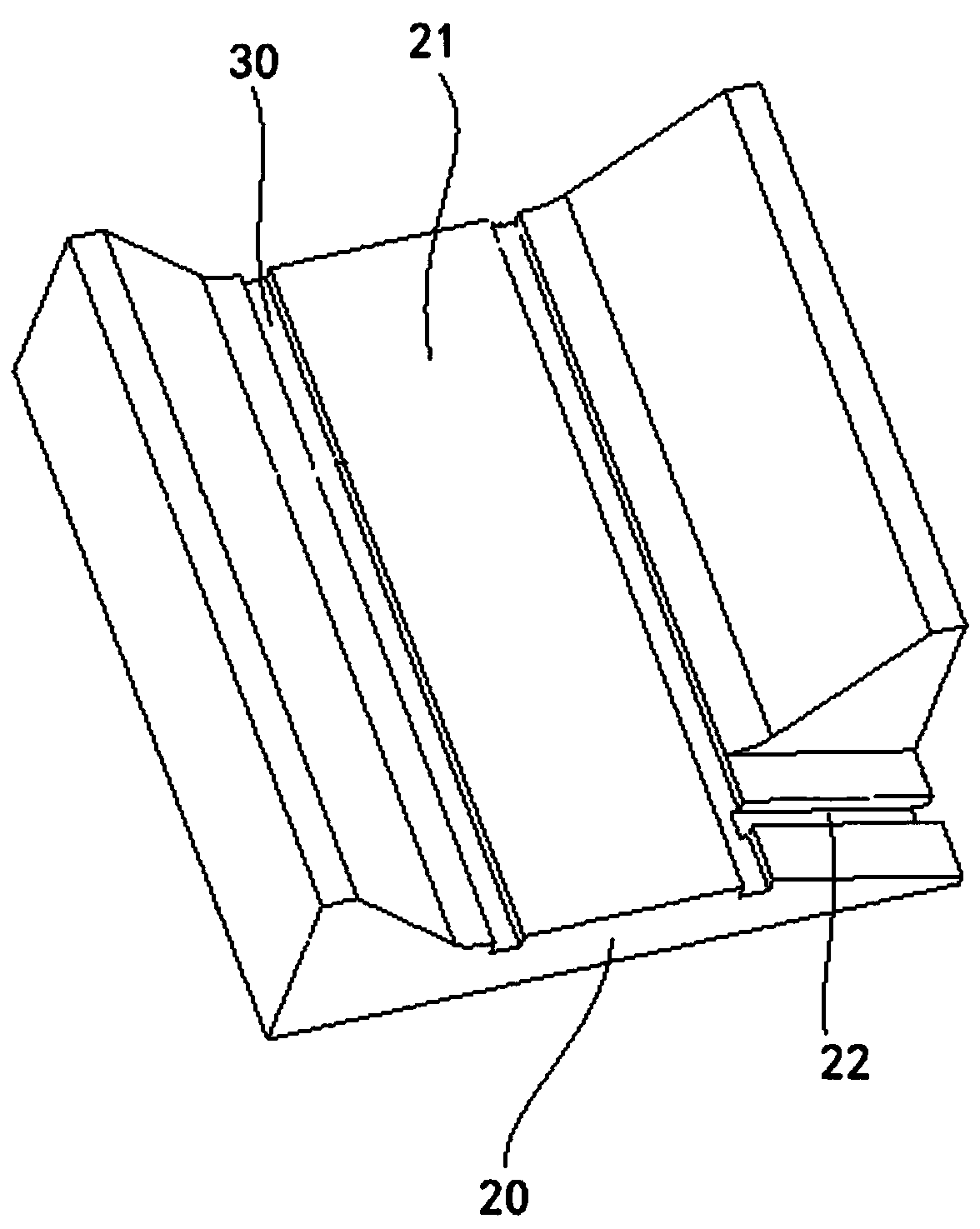

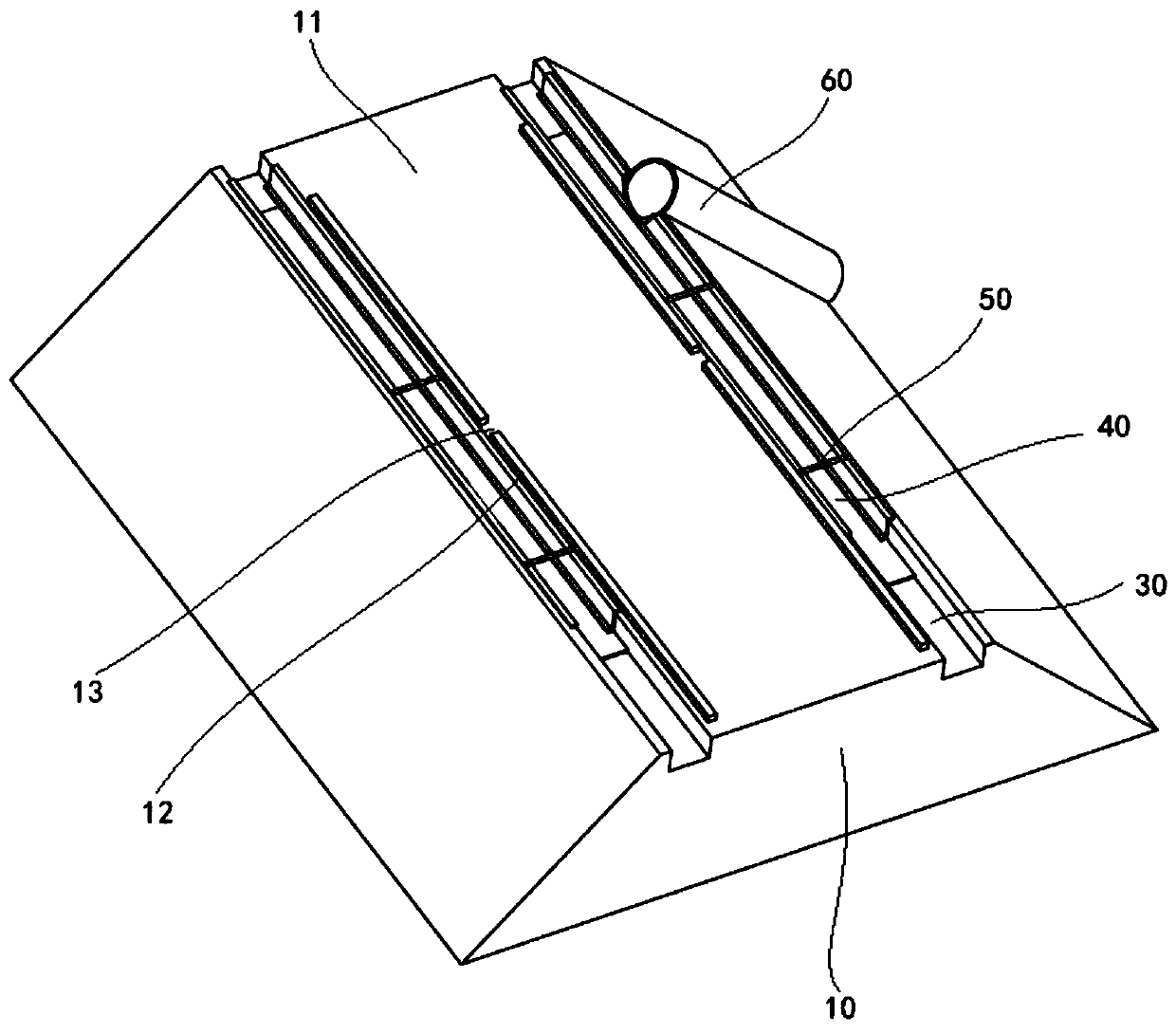

[0045] The new expressway of this embodiment, on the basis of the high fill section described in Embodiment 1, in figure 2 In the excavated road section shown, a drainage groove 40 made of corrugated steel as described in the first embodiment is also arranged in the side ditch 30 . In addition, at the junction of the high fill roadbed 10 and the excavated roadbed 20, a centralized drainage pipe made of steel bellows is also provided.

[0046] In this embodiment, both the high-fill drainage system and the excavation drainage system adopt the drainage groove made of corrugated steel and the centralized drainage drainage pipe made of steel corrugated pipe, which further improves the drainage performance and Safety performance, can adapt to more terrains, and has lower requirements on foundation bearing capacity and flatness, which is beneficial to improve the uneven settlement problems in special foundation structures such as permafrost, soft soil, expansive soil, and collapsibl...

Embodiment 3

[0048] A kind of road drainage system of the present embodiment has such as Figure 4 The shown drainage groove 40 for adapting to the side ditch of the road, the drainage groove 40 is formed by connecting end to end of several drainage groove units, and the adjacent drainage groove units are connected by sealant, gasket or other conventional, Seal with a suitable sealing method to prevent water leakage at the interface. Wherein, the drainage tank unit includes a tank bottom 41 and tank walls 42 arranged on both sides of the tank bottom. It should be noted that the tank wall 42 and the tank bottom 41 can be integrally formed, or can be designed separately and fixed together by bolts, welding and other means.

[0049] As a preference, in this embodiment, as Figure 4 As shown, the tank wall 42 and the tank bottom 41 are designed separately. Wherein the groove wall 42 has a lower edge 43 for connecting with the groove bottom 41 and an upper edge 44 for overlapping the high fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com