Steam condensation water complementary energy utilization device

A steam condensate and residual energy technology, applied in energy-saving heating/cooling, climate sustainability, lighting and heating equipment, etc., can solve the problems of high pressure, energy waste, etc., and achieve the effect of improving utilization rate, stable and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

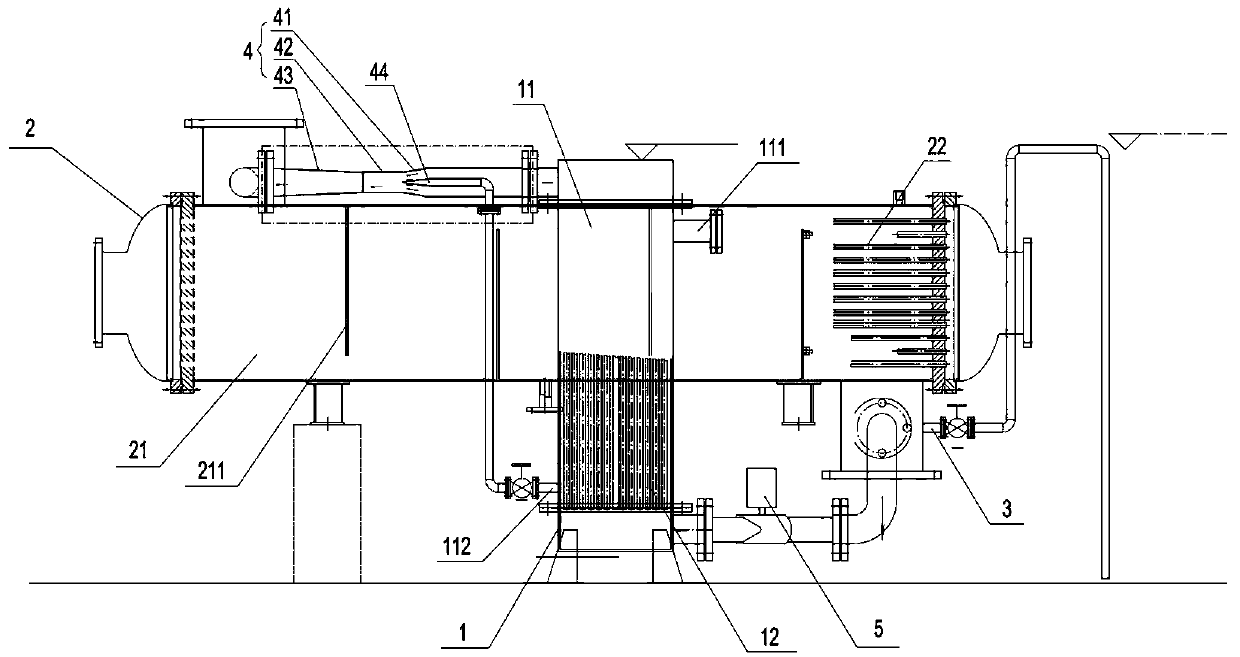

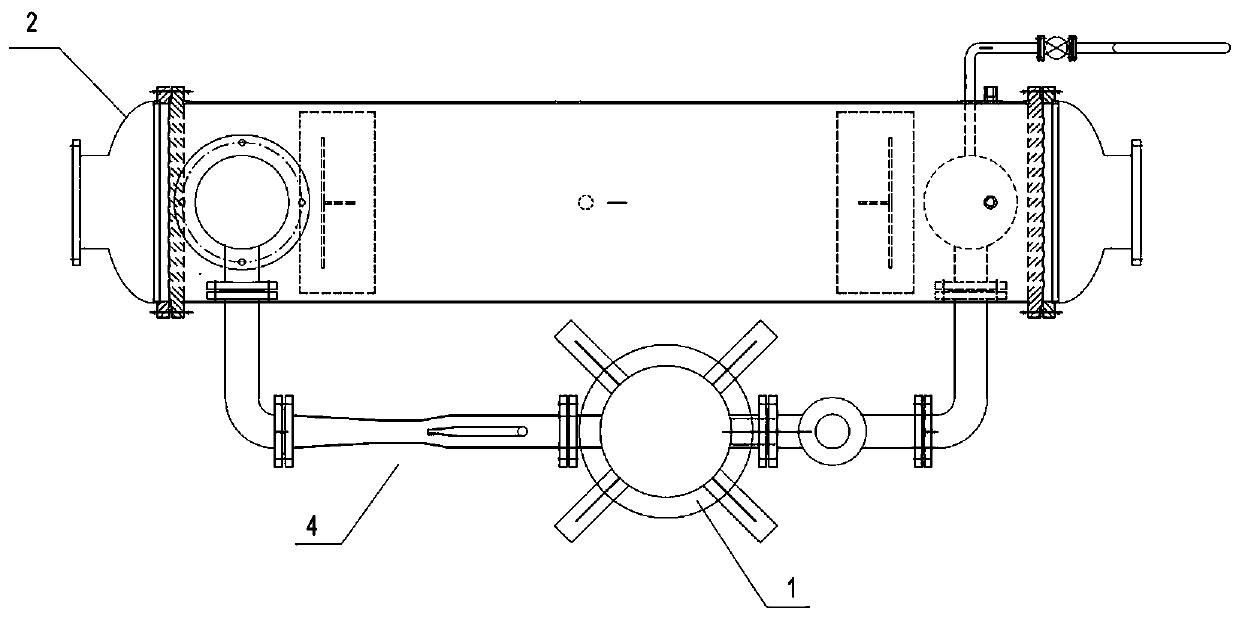

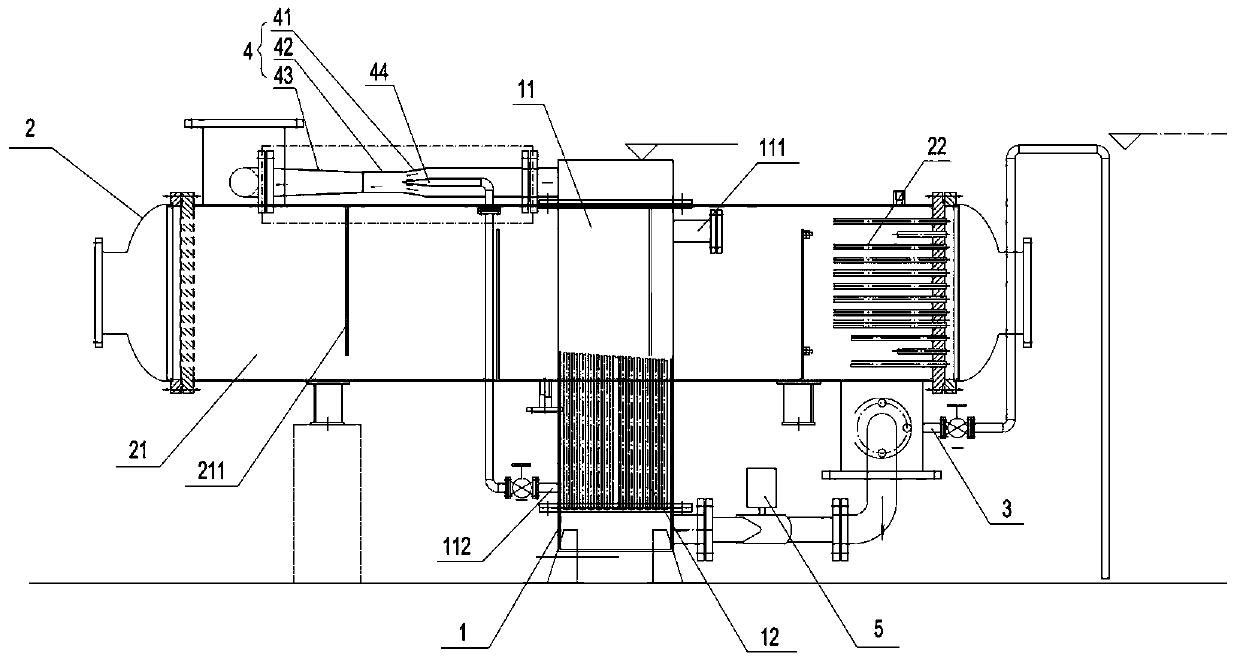

[0023] A steam condensed water residual energy utilization device, comprising a gas-water heat exchanger 1, a water-water heat exchanger 2. The gas-water heat exchanger 1 includes a first heat exchange cavity 11 passing through the first heat exchange cavity 11 The first heat exchange tube group 12 of the first heat exchange cavity 11 is respectively provided with an air inlet 111 and a water outlet 112 at both ends; the water-to-water heat exchanger 2 includes a second heat exchange cavity 21 that penetrates The second heat exchange tube group 22 of the second heat exchange cavity 21; the water outlet end and the water inlet end of the first heat exchange tube group 12 are respectively connected to the water inlet end and the water outlet end of the second heat exchange cavity 21, The water outlet 112 is connected to the water inlet end of the second heat exchange cavity 21; the water outlet end of the second heat exchange cavity 21 is provided with a drain port 3.

[0024] Work...

Embodiment 2

[0027] On the basis of embodiment 1, a water ejector 4 is provided between the water outlet end of the first heat exchange tube group 12 and the water inlet end of the second heat exchange cavity 21, and the water outlet 112 is connected to The water ejector 4. The water ejector 4 first mixes two water bodies with different temperatures and different flow rates into one body, and then passes into the second heat exchange cavity 21, which can effectively ensure the stability of the water circulation and heat exchange effect. Specifically, the water ejector 4 includes a shrink tube 41, a mixing tube 42, and a diffusion tube 43 in sequence along the flow direction of the internal water body. The shrink tube 41 is provided with a nozzle 44, and the water inlet end of the nozzle 44 communicates with each other. The water outlet 112. The water-water ejector 4 gradually reduces the diameter of the fluid to be ejected through the shrink tube 41, and mixes the high-speed ejection fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com