Lock opening and closing mechanism for bottle blowing machine die frame

A locking mechanism and a bottle blowing machine technology, applied in the field of bottle blowing, can solve the problems of large reverse holding force, serious accident, large holding force, etc., and achieve the reduction of impact and noise, reliable operation, and no deviation in size and shape and position. sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

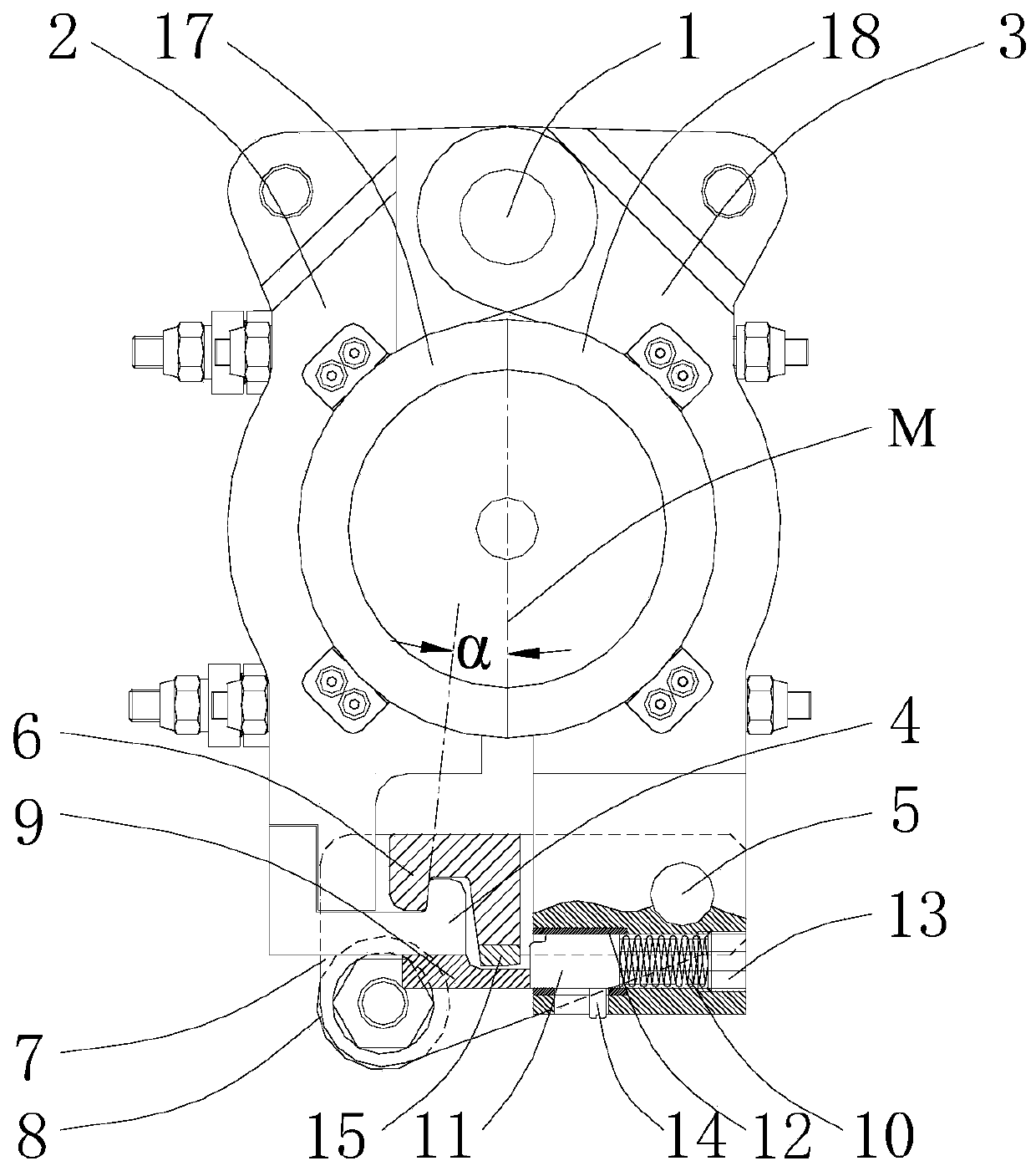

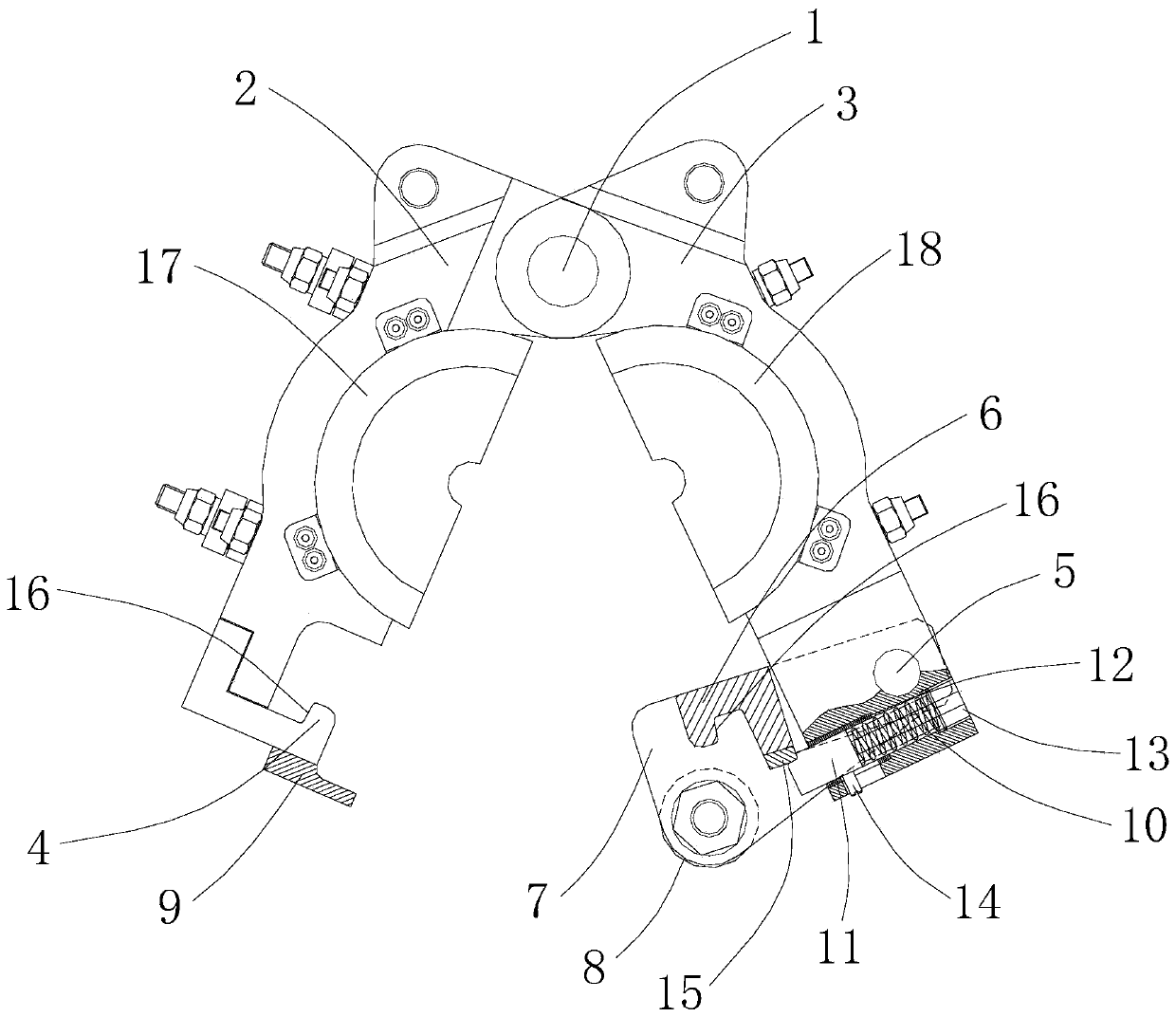

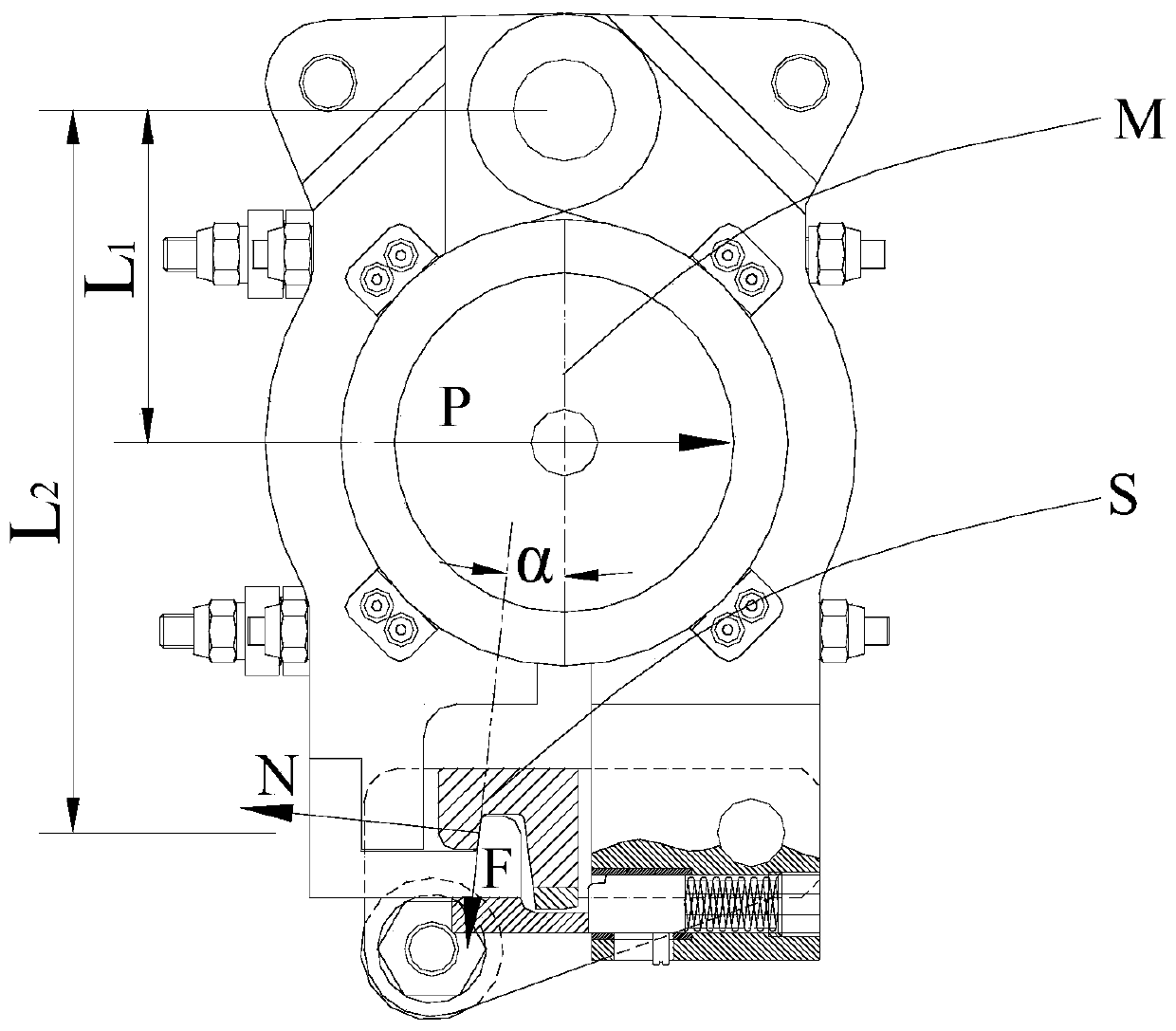

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] see Figure 1-2 As shown, the above-mentioned opening and closing mechanism of the mold frame of the bottle blowing machine, the bottle blowing machine includes a frame, and the first parts for opening and closing molds that are arranged on the frame and are used to cooperate with each other can rotate around the first axis line 1 respectively. Formwork 2 and second formwork 3, the first mold 17 and the second mold 18 that are respectively arranged on the first formwork 2 and the second formwork 3 inside, the first mold 17 and the second mold 18 are mutual when mold closing. Enclosed to form a bottle blowing cavity. In this embodiment, the first axis line 1 extends along the vertical direction.

[0034] The above-mentioned opening and closing mechanism of the blow molding machine mold frame includes a fixed claw 4 arranged on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com