Novel FRP floating tray construction method

A construction method, the technology of FRP, applied in the direction of large containers, containers, packaging, etc., can solve the problems of high manufacturing cost, complex construction equipment, slow construction speed, etc., to speed up the construction speed, easy to ensure process and quality, and small human error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

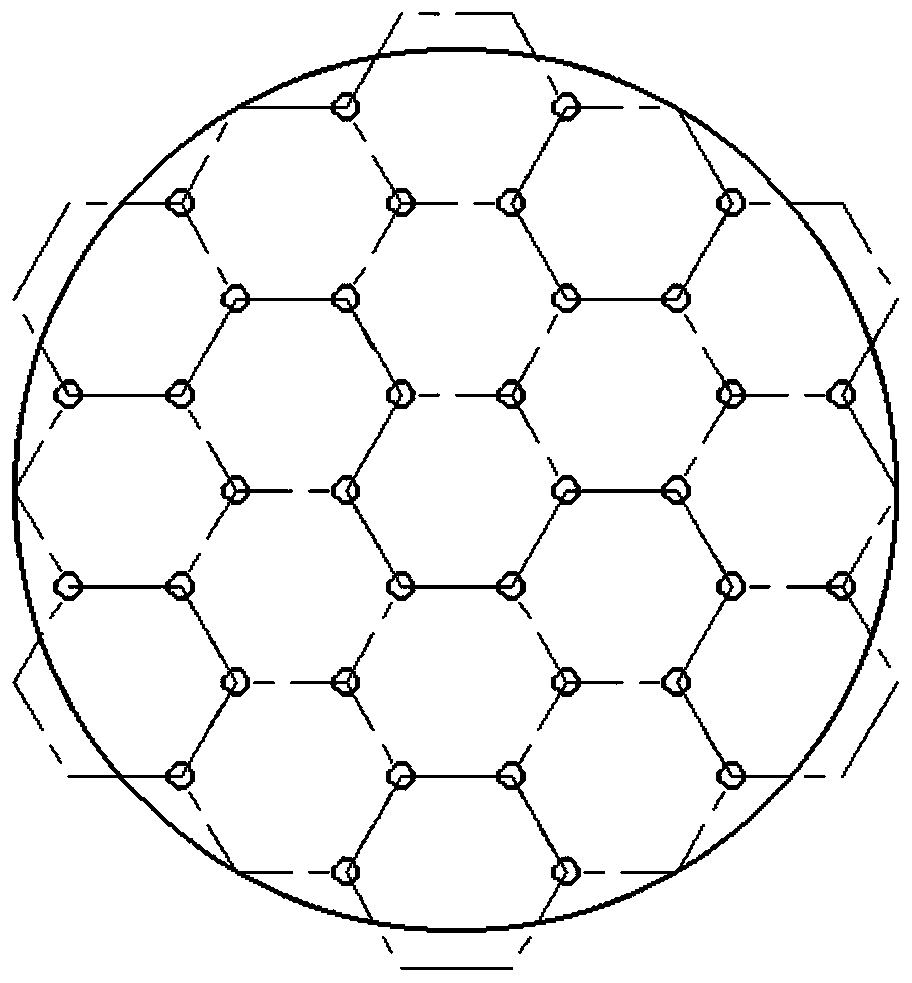

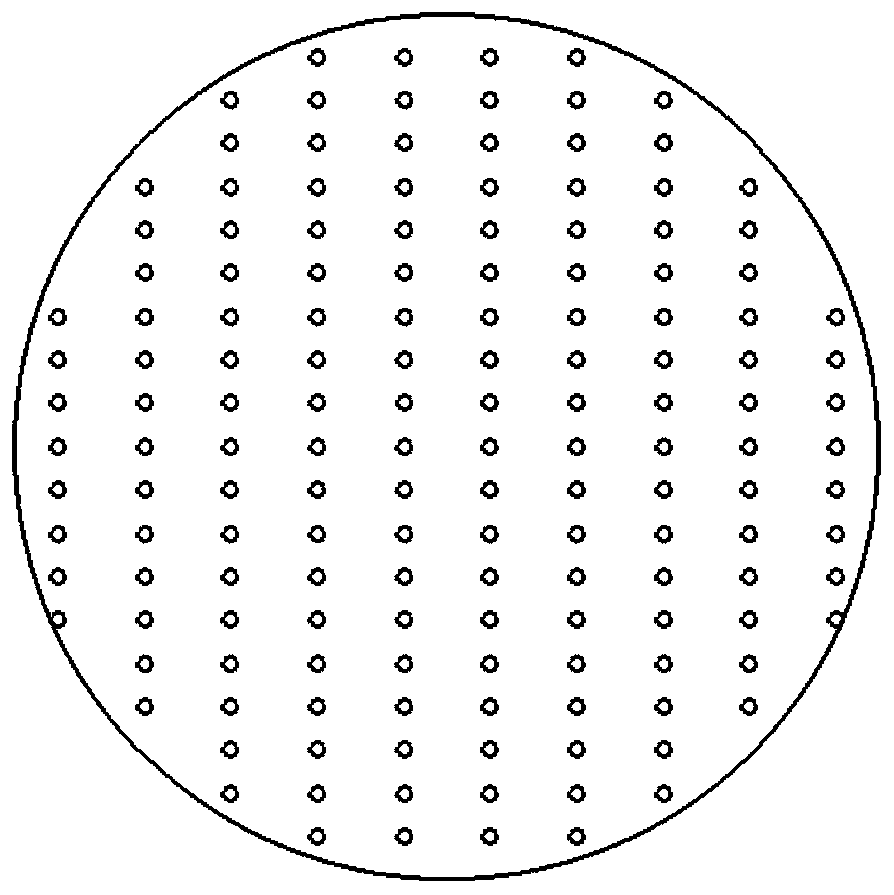

[0058] The construction method of the present invention uses the FRP pultrusion profile as the core plate of the FRP floating plate to replace the existing honeycomb core plate, and uses the FRP light-cured prepreg as the bottom layer and the top layer of the FRP floating plate on the upper and lower sides of the pultrusion profile Reinforcing layer. Core board structure see figure 2 shown.

[0059] The specific construction process is to combine the characteristics of light-cured resin and FRP profiles. The steps are as follows:

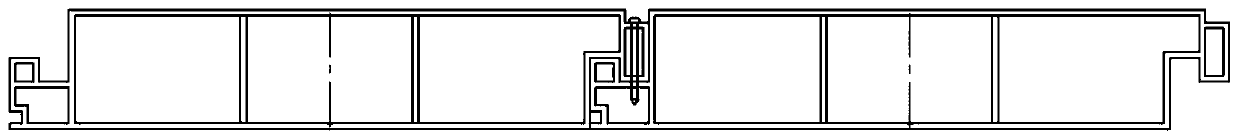

[0060] 1. Welding floating disc outriggers

[0061] In order to ensure the tightness of the FRP floating plate, no outriggers are set on the FRP floating plate body, and the outriggers are welded to the bottom of the storage tank. The outriggers are made of 100*100mm H-shaped steel as columns, and the strength of the outriggers is far higher than the existing outriggers. The number of outriggers is only about one-fifth of that of ordinary floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com