Single-axis anti-eccentric system for small fan bearing

A fan shaft and uniaxial technology, applied in the field of uniaxial anti-eccentricity system, can solve the problems of large force, failure to restore the original shape, and low practical value of the shaft sleeve, achieve good economic and social benefits, and improve resistance to deformation The effect of ability, good promotion and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

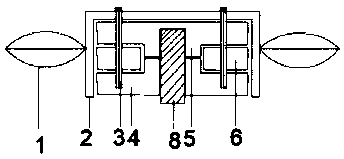

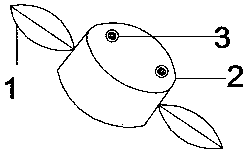

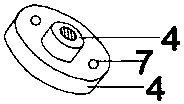

[0016] Embodiment of the present invention: a single-axis anti-eccentric system for small fan bushings, as attached Figure 1-5 As shown, there is an inverted U-shaped fan blade housing 2, and a plurality of fan blades 1 are evenly fixed on the outer housing of the fan blade housing 2, and first protrusions are sequentially arranged inside the fan blade housing 2 from top to bottom. Shaped plastic part 5, annular plastic part 6 and the second convex plastic part 4, the protruding ends of the first protruding plastic part 5 and the second protruding plastic part 4 are arranged oppositely, and its protruding ends all snap into the circle In the round hole of the annular plastic part 6, the screw 3 passes through the fan blade case 2, the first convex plastic part 5 and the annular plastic part 6 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com