Box falling test device

A technology for testing equipment and boxes, applied in the field of box drop testing equipment, can solve the problems of high work intensity, low detection efficiency, inaccurate test results, etc., and achieve the effect of improving efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

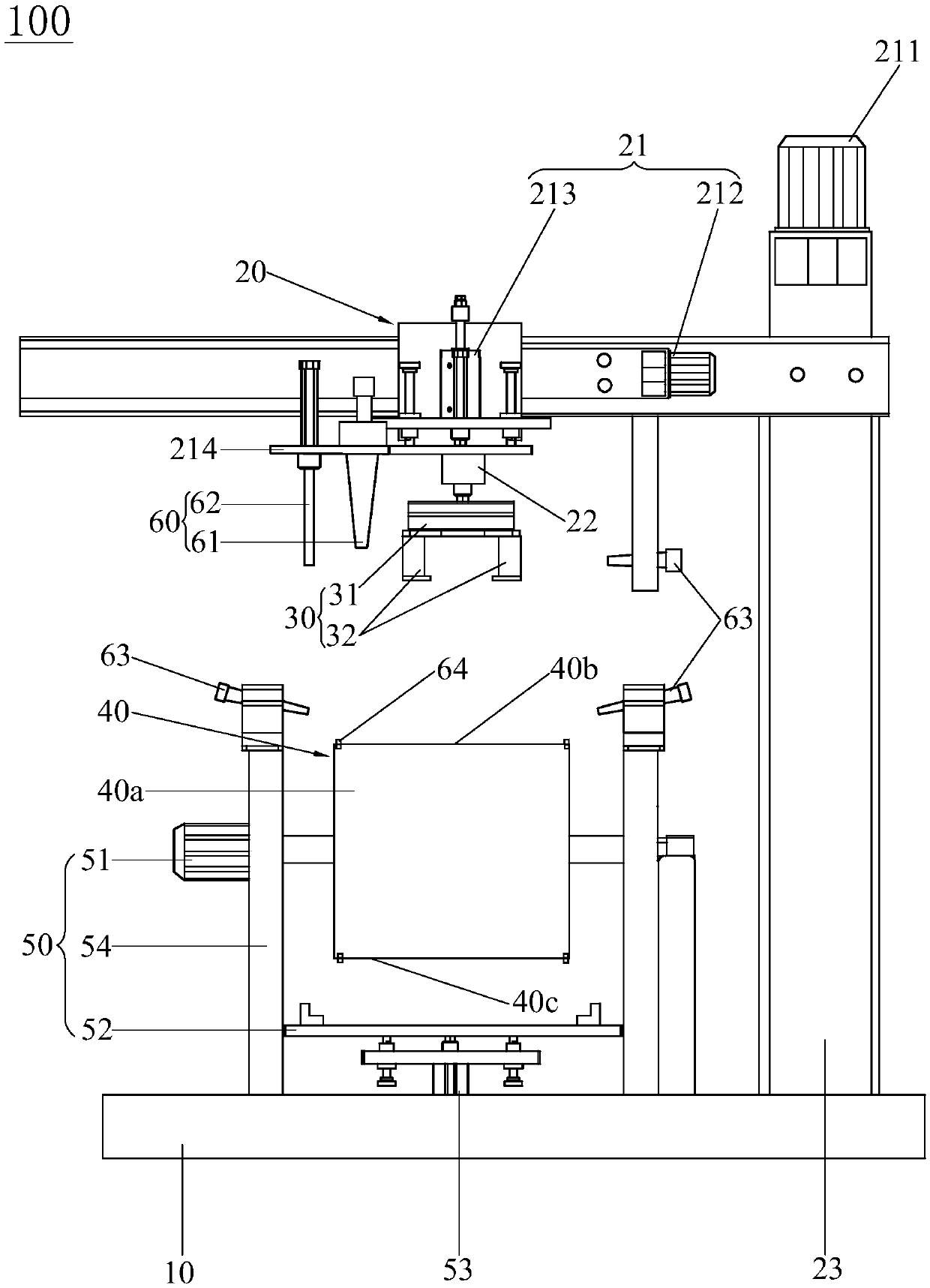

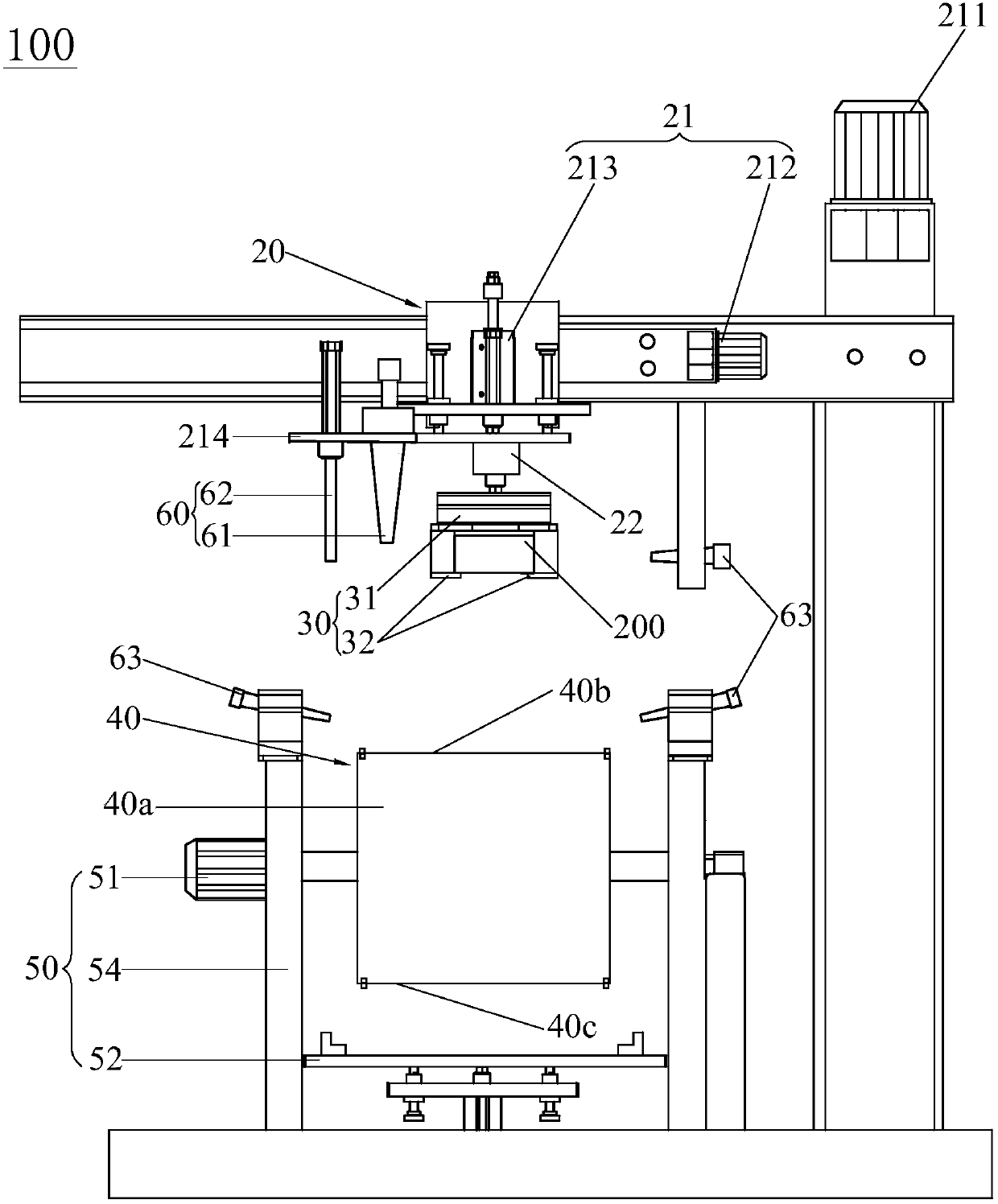

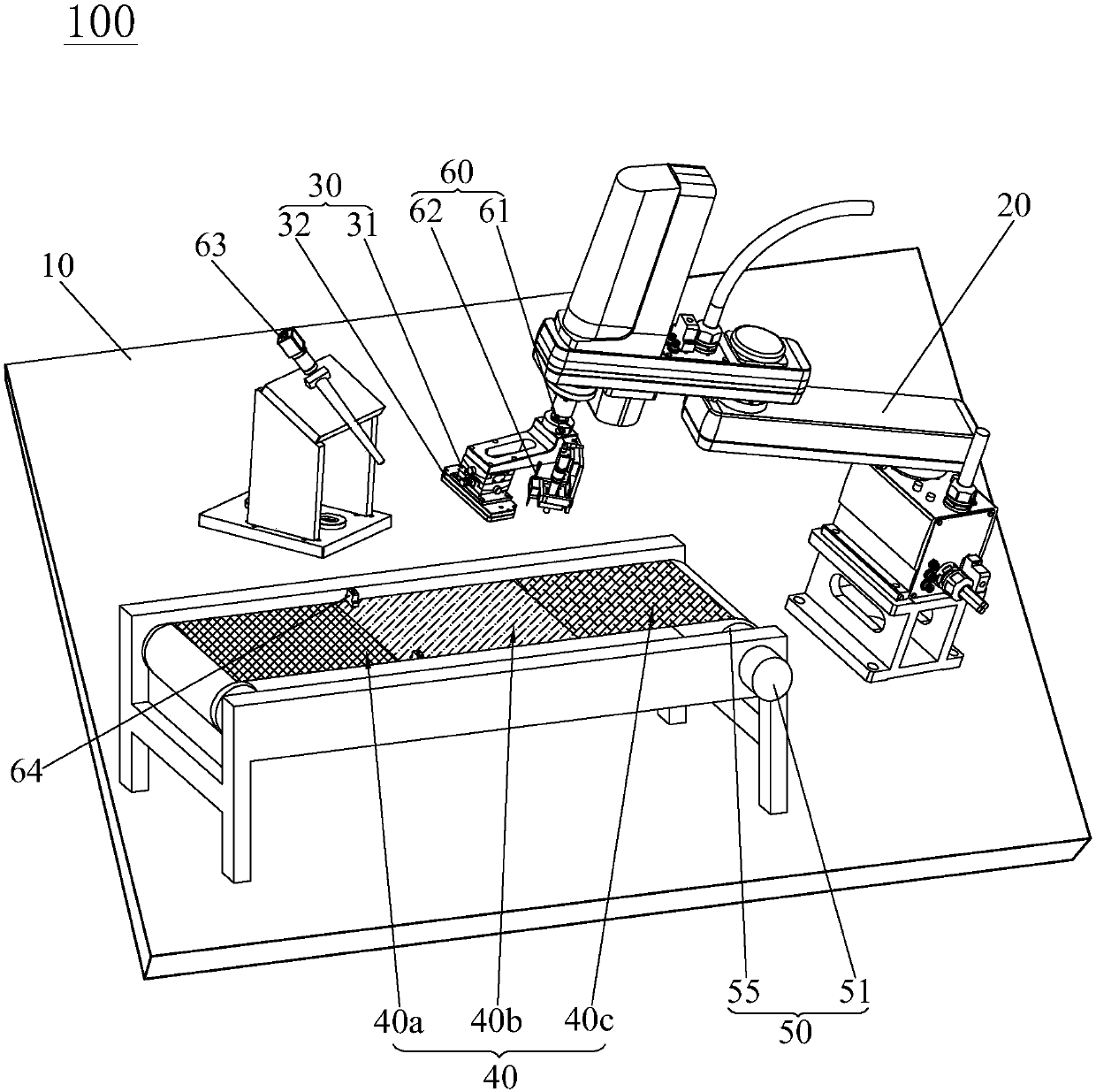

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0028] Please refer to Figure 1 to Figure 3 , the present invention provides a box drop test device 100, which is suitable for packaging the products packed in the box 200, and optimizes the packaging through the drop test in order to better protect the products in the box 200. The box body drop test equipment 100 comprises a bearing platform 10 and a drive mechanism 20 located on the bearing platform 10, a pick-and-place mechanism 30, a test ground 40, a test ground conversion mechanism 50 and a controller (not shown in the figure). out). The controller is electrically connected with the driving mechanism 20 , the pick-and-place mechanism 30 and the test ground conversion mechanism 50 , so as to effectively ensure the degree of automation of the box drop test device 100 of the present invention. Wherein, the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com