Array substrate, preparation method thereof and display device

A technology of array substrates and substrate substrates, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as increased production costs and expensive masks, and achieves reductions in process preparation costs and savings in masks. Stencil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

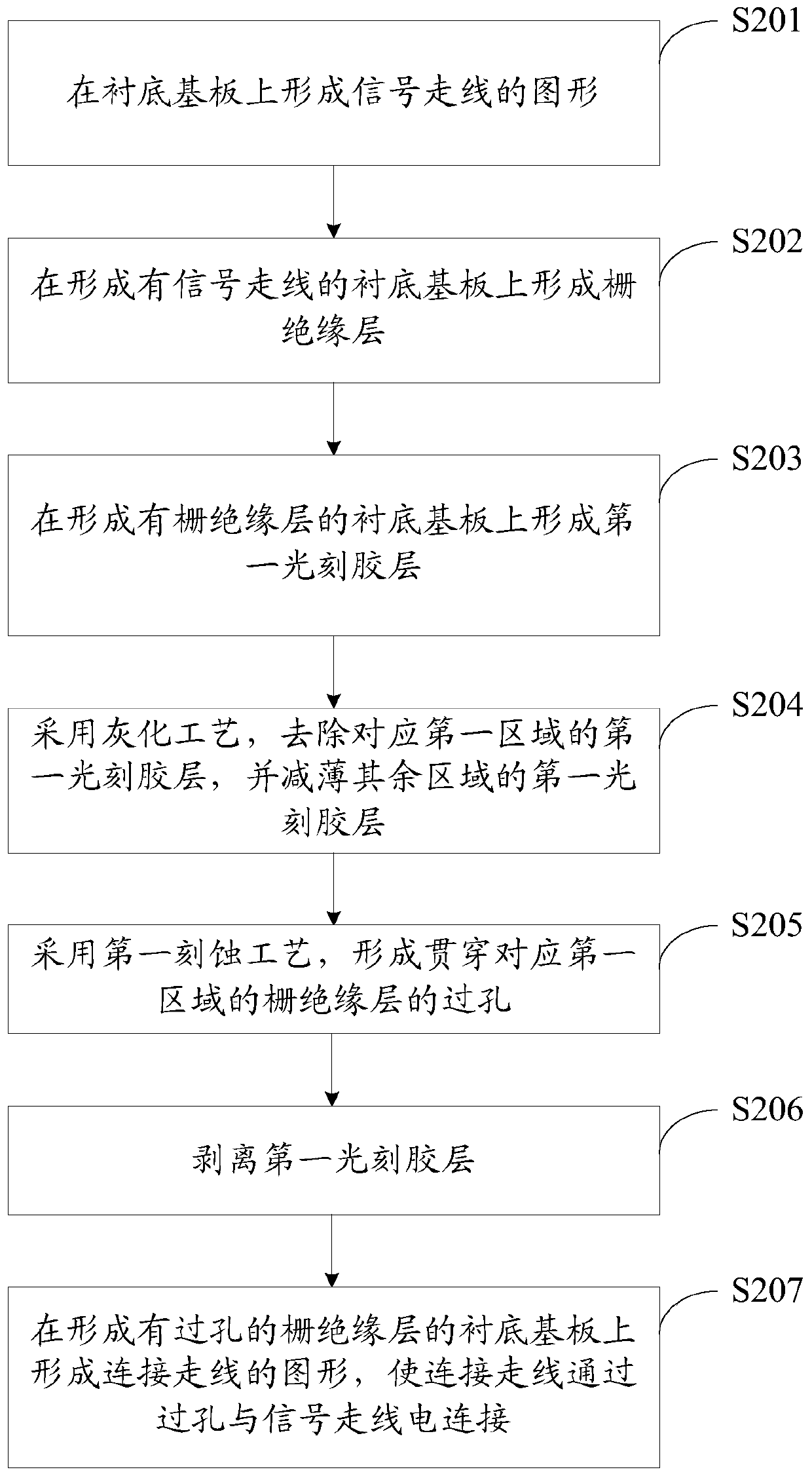

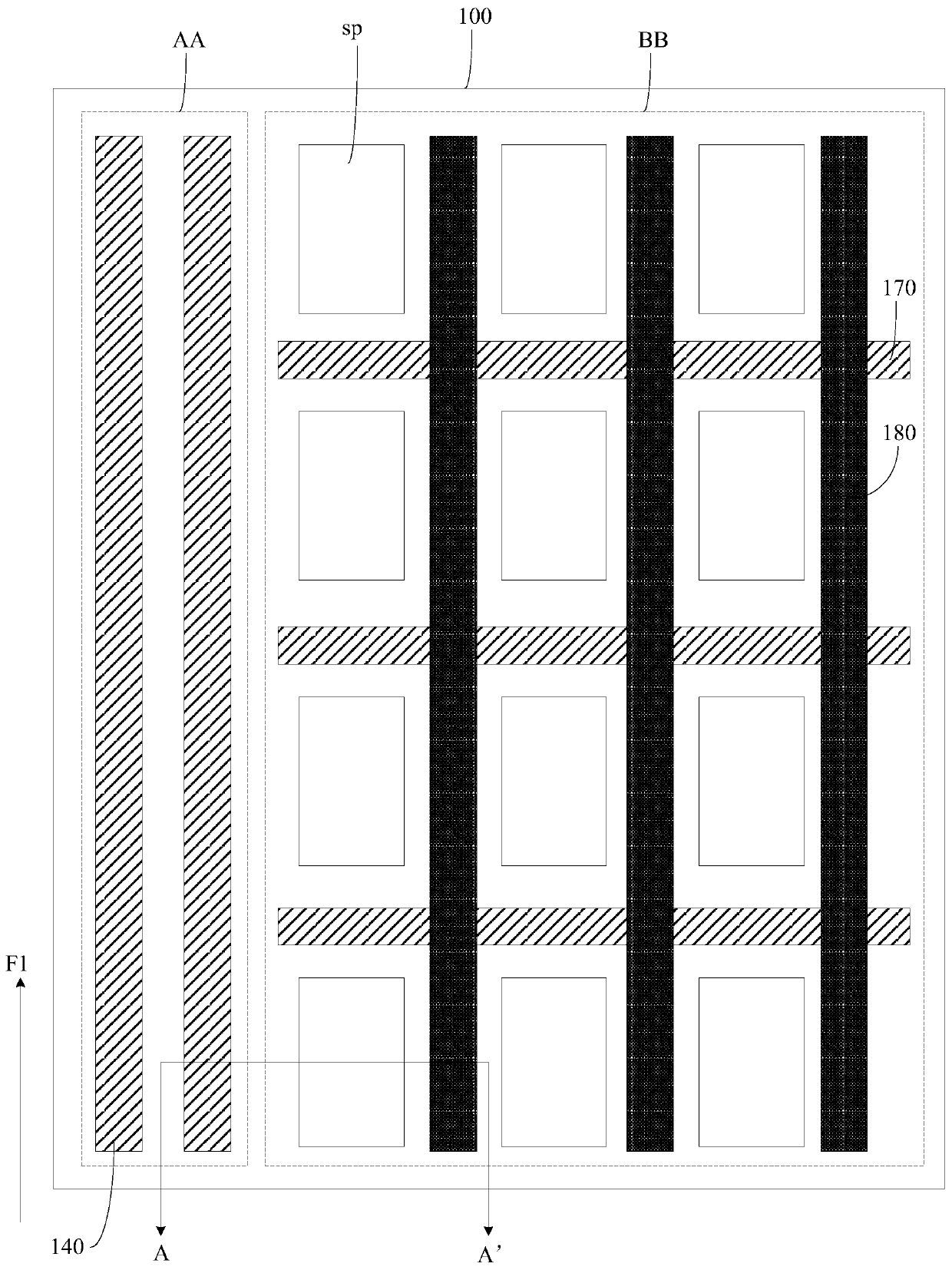

[0051] Based on this, an embodiment of the present invention provides a method for preparing an array substrate, such as figure 2 As shown, the following steps may be included:

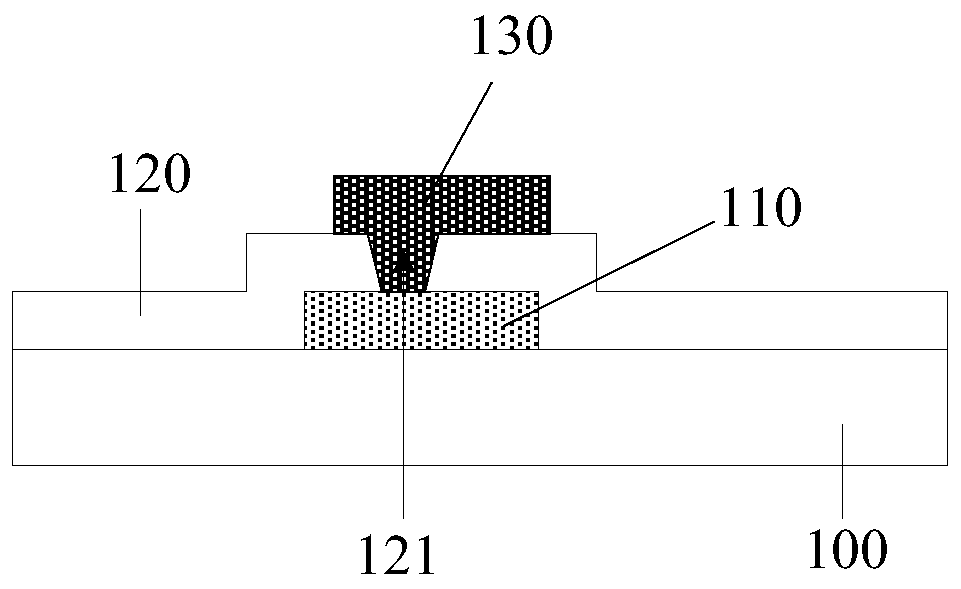

[0052] S201. Form a pattern of signal traces on the base substrate; wherein, in a direction perpendicular to the extension direction of the signal traces, the cross section of the signal traces has a first area and a second area, and on a plane perpendicular to the base substrate, The thickness of the first region is greater than the thickness of the second region. Further, during specific implementation, the first area may be the central area of the signal routing, and the second area may be the edge area of the signal routing;

[0053] S202, forming a gate insulating layer on the substrate on which the signal traces are formed;

[0054] S203, forming a first photoresist layer on the base substrate on which the gate insulating layer is formed; wherein, the thickness of the first photoresist laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com