Fully automatic sprout planting room

A fully automatic, sprout technology, applied in germination equipment, seed and rhizome treatment, botanical equipment and methods, etc., can solve the problems of difficult spraying, affecting rooting, large water consumption, etc., to improve disturbance and increase mining. Substance content, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

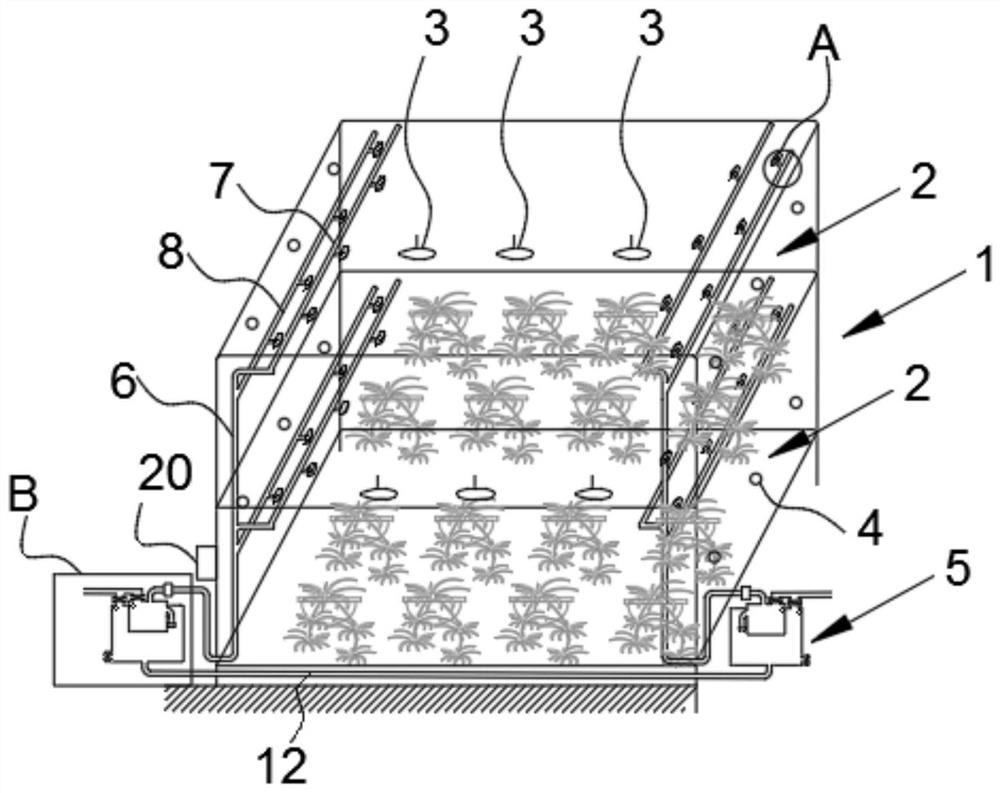

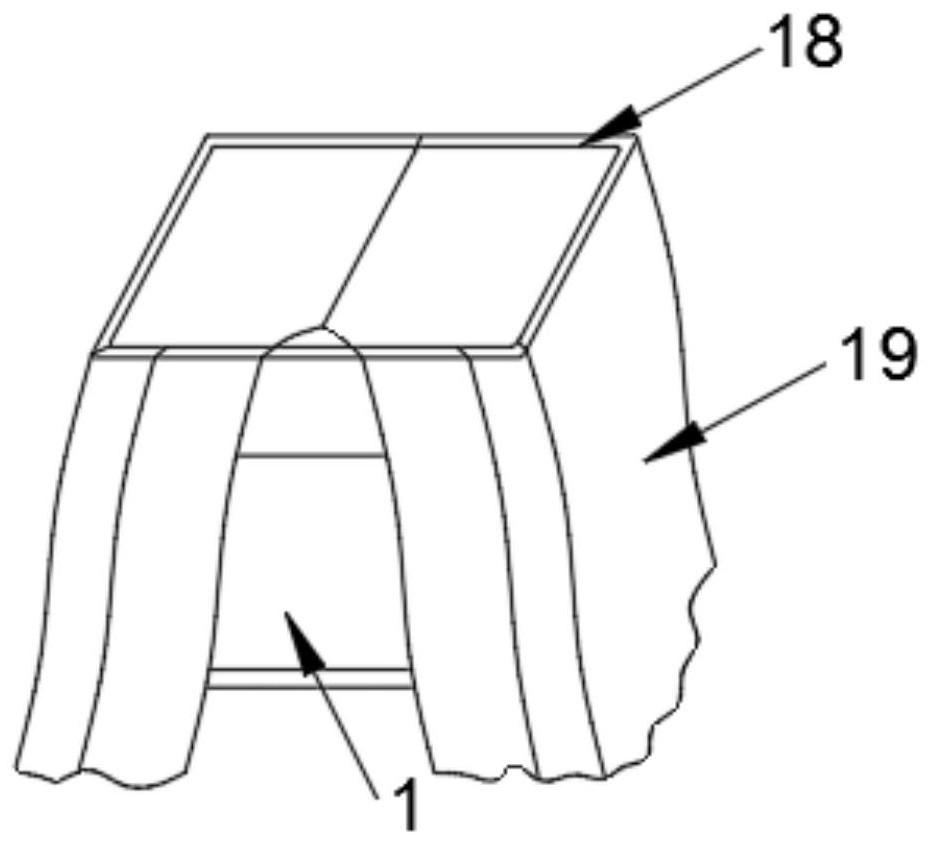

[0045] Embodiment: a kind of fully automatic bean sprouts planting room, as Figure 1-Figure 7 As shown, it includes a planting room body 1, the interior of the planting room body is provided with a plurality of sprout cultivation layers 2, and the top of each of the sprout cultivation layers is provided with a plurality of plant supplementary lights 3, and the planting room The inner wall of the main body is provided with a plurality of temperature sensors 4, a plurality of heating coils and a thermostat 21, and a plurality of the heating coils are electrically connected to the thermostat, and a plurality of the temperature sensors are evenly distributed on the inner wall of the planting room body , a plurality of the heating coils are equally spaced along the height direction of the implant room body;

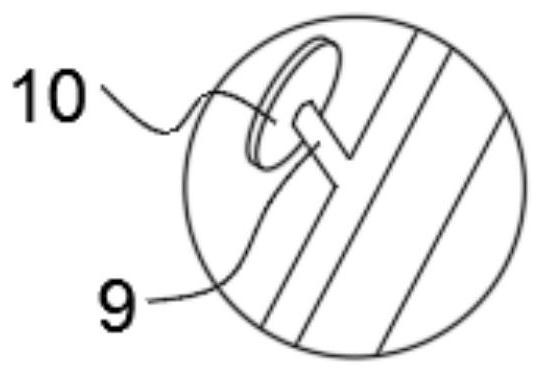

[0046] There is at least one set of spraying devices in the planting room body, and each spraying device includes a water supply tank 5, a main water supply pipe 6 and severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com