Three-way pipe forming method, forming device and forming system

A forming method and a forming device technology, which are applied in the field of automatic processing equipment, can solve problems such as complicated procedures and few structural types of three-way pipes, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

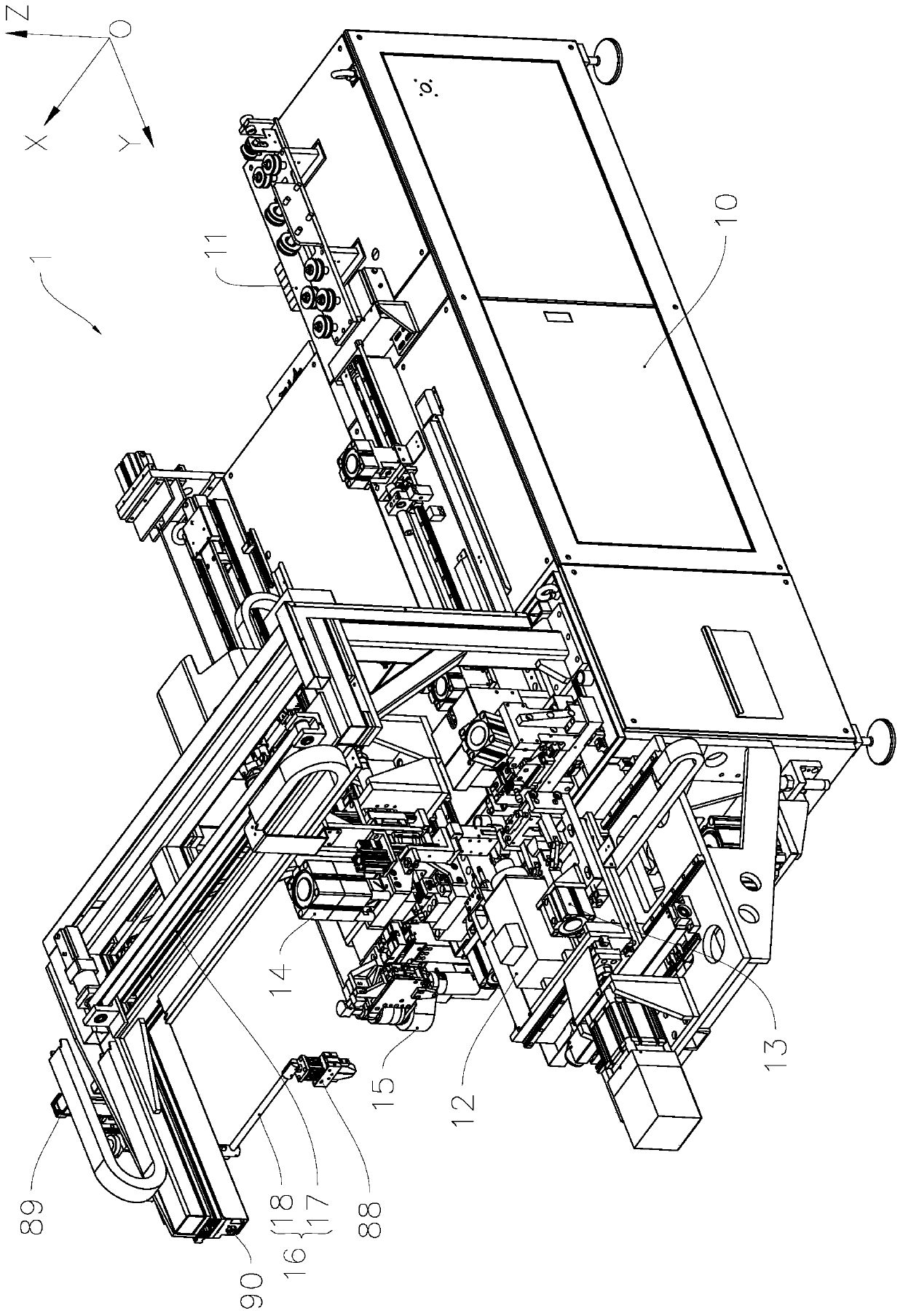

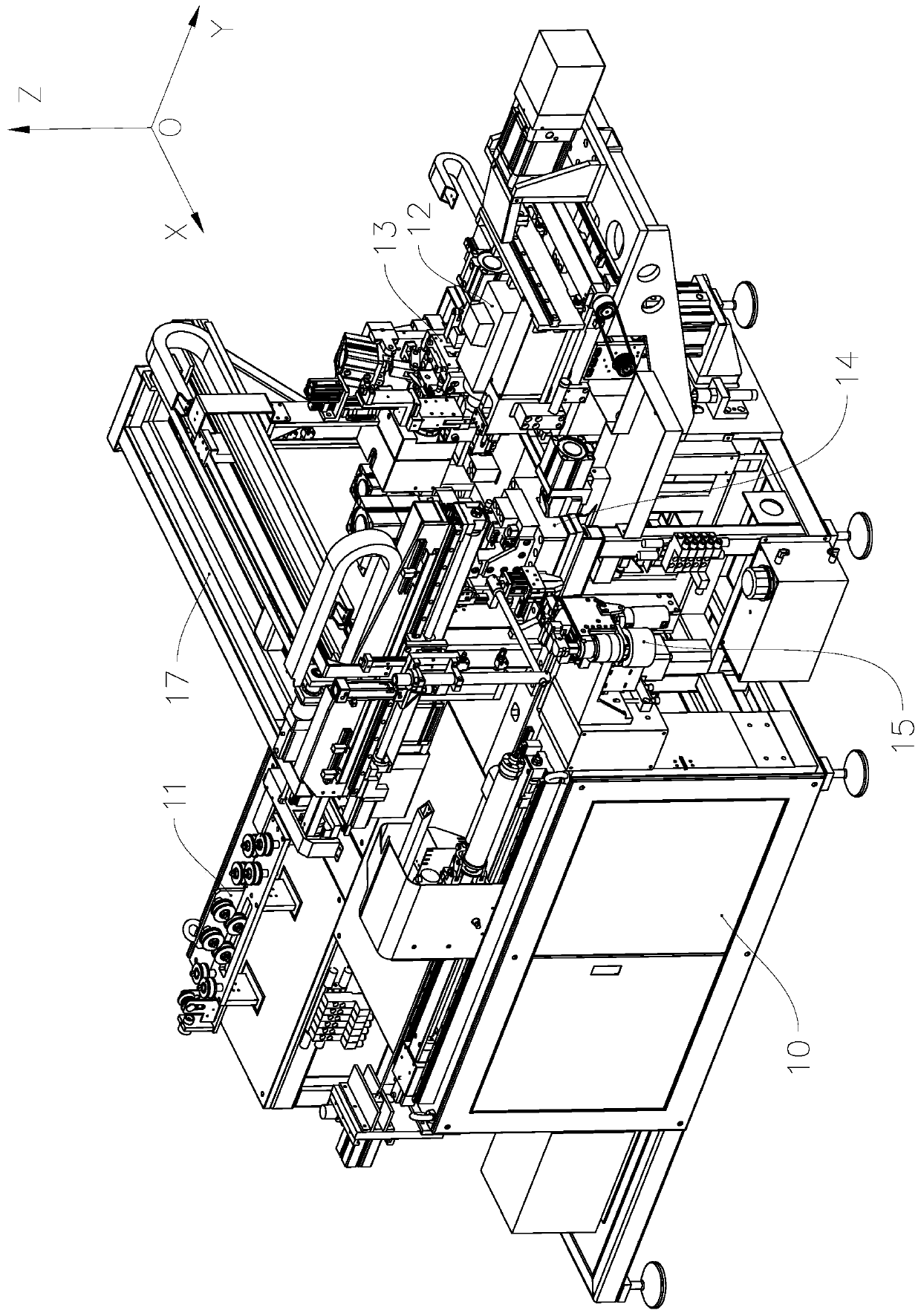

[0043] see Figure 1 to Figure 17 The three-way pipe forming system 1 of the present invention includes a frame 10 and a feeding device 11 installed on the frame 10, a flaring device 12, a forming device 13, a pipe end processing device 14, a pipe bending device 15 and a moving device. The material manipulator system 16, the material transfer manipulator system 16 is used to sequentially transfer pipe materials between each device, the material transfer manipulator system 16 includes a traverse manipulator system 17 and a bend pipe loading and unloading manipulator system 18, so that each device can be processed according to the process sequence , sequentially process the pipe material to obtain such as Figure 18 Tee pipe 01 of the structure shown.

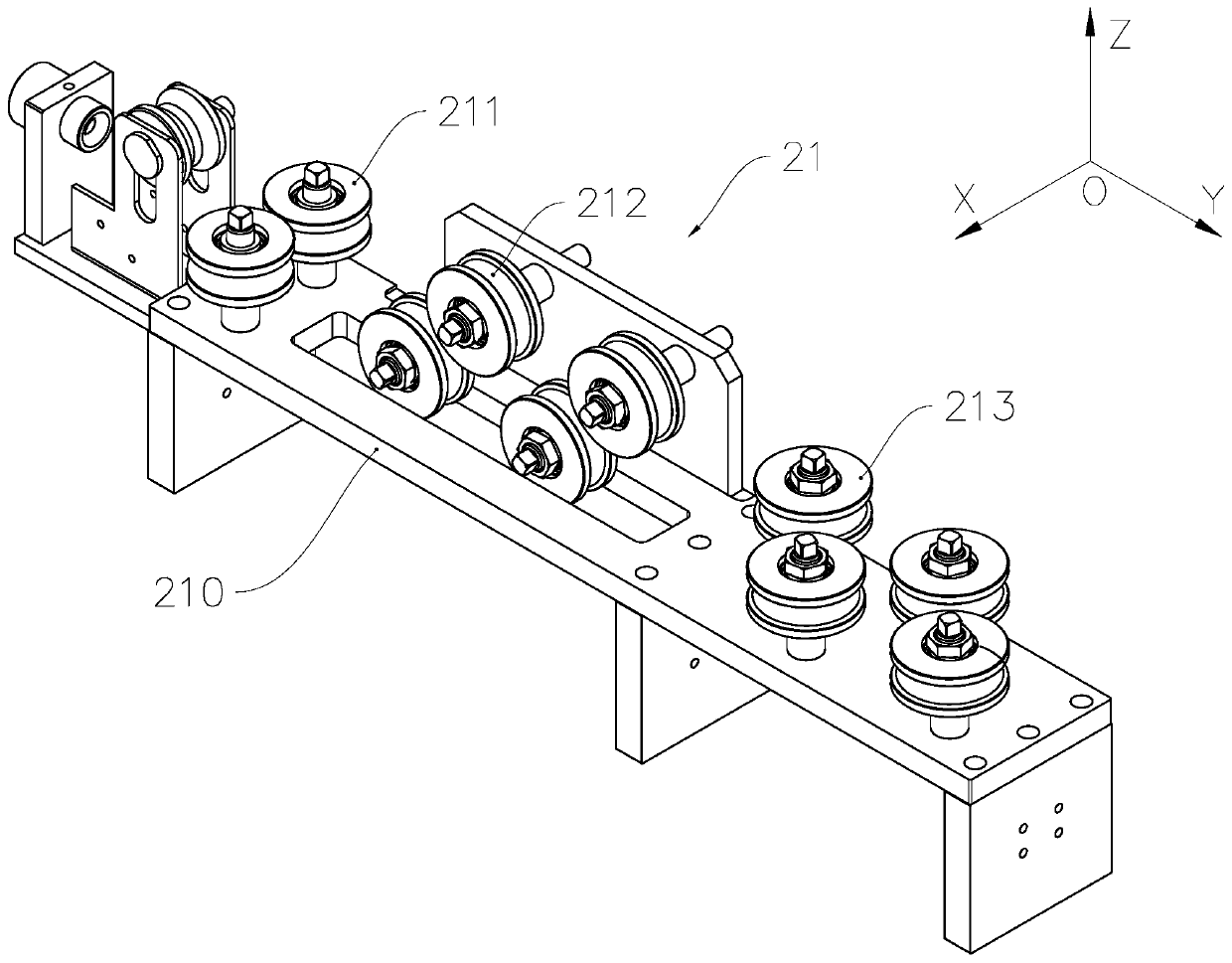

[0044] like Figure 1 to Figure 5 and Figure 8 As shown, the feeding device 11 includes a straightening unit 21 , a feeding unit 22 , a fixed pulling die 23 , a chipless rotary cutting head 24 , a moving pulling die 25 and a p...

Embodiment 2

[0078] As an explanation of Embodiment 2 of the molding system of the present invention, only the differences from Embodiment 1 of the above-mentioned molding system will be described below.

[0079] see Figure 19 , the extruded protrusions 71, 72 of the distance expansion unit are used to squeeze the gap 61020 between the two mandrel seats 61, 62 to expand the gap, thereby driving the distance between the two forming mandrels 63, 64 to expand , that is, in this embodiment, the distance expanding unit is used to squeeze out the gap between the two mandrel seats. At this time, the stress-bearing part on the non-forming rod part is the fixed section of the forming mandrel on the mandrel seat.

[0080] refer to figure 1 In the structure shown, for the traversing manipulator system 17 and the bending pipe loading and unloading manipulator system 18, the degree of freedom of movement along the Y-axis can be added to the traversing manipulator system 17 to form a three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com