Processing technology of pure oxygen metal burner distributor and distributor based on same

A processing technology and distributor technology, which is applied in the field of coke oven gas distributor, can solve the problems of economic loss of enterprises, coke oven gas wearing parts, and process operation in harsh environment, so as to increase market share and reduce technical level requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

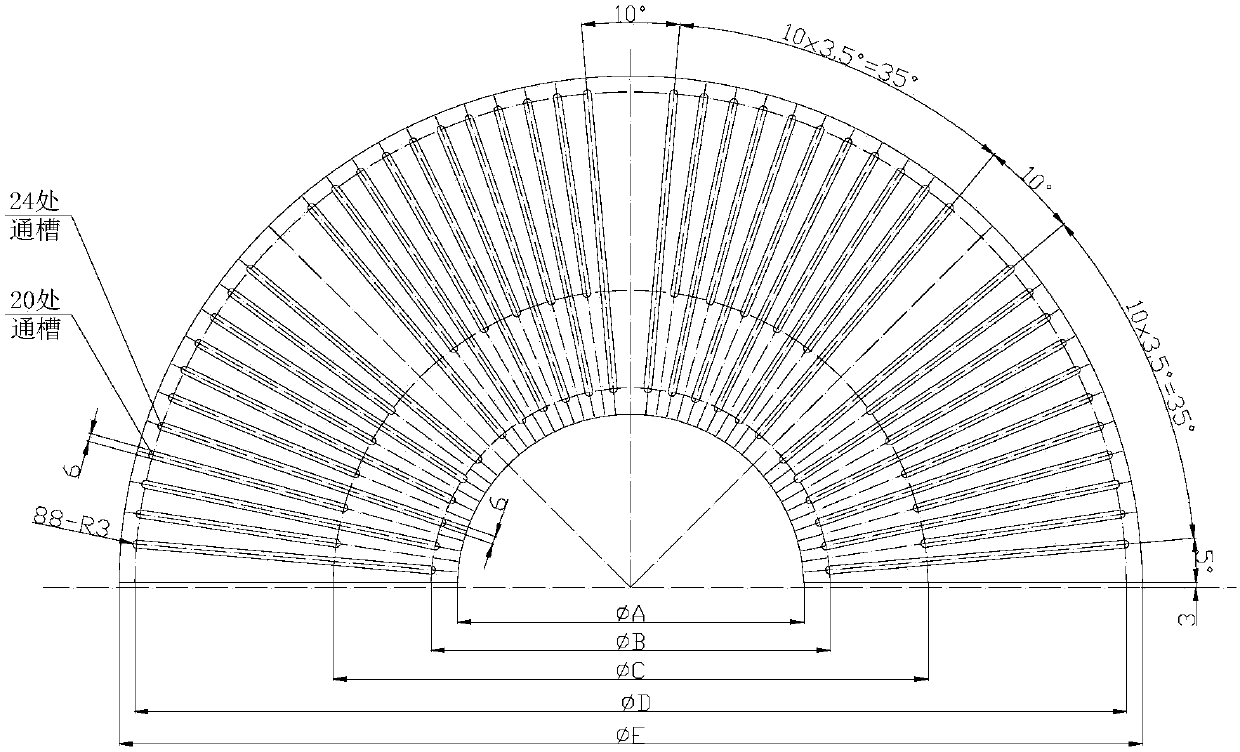

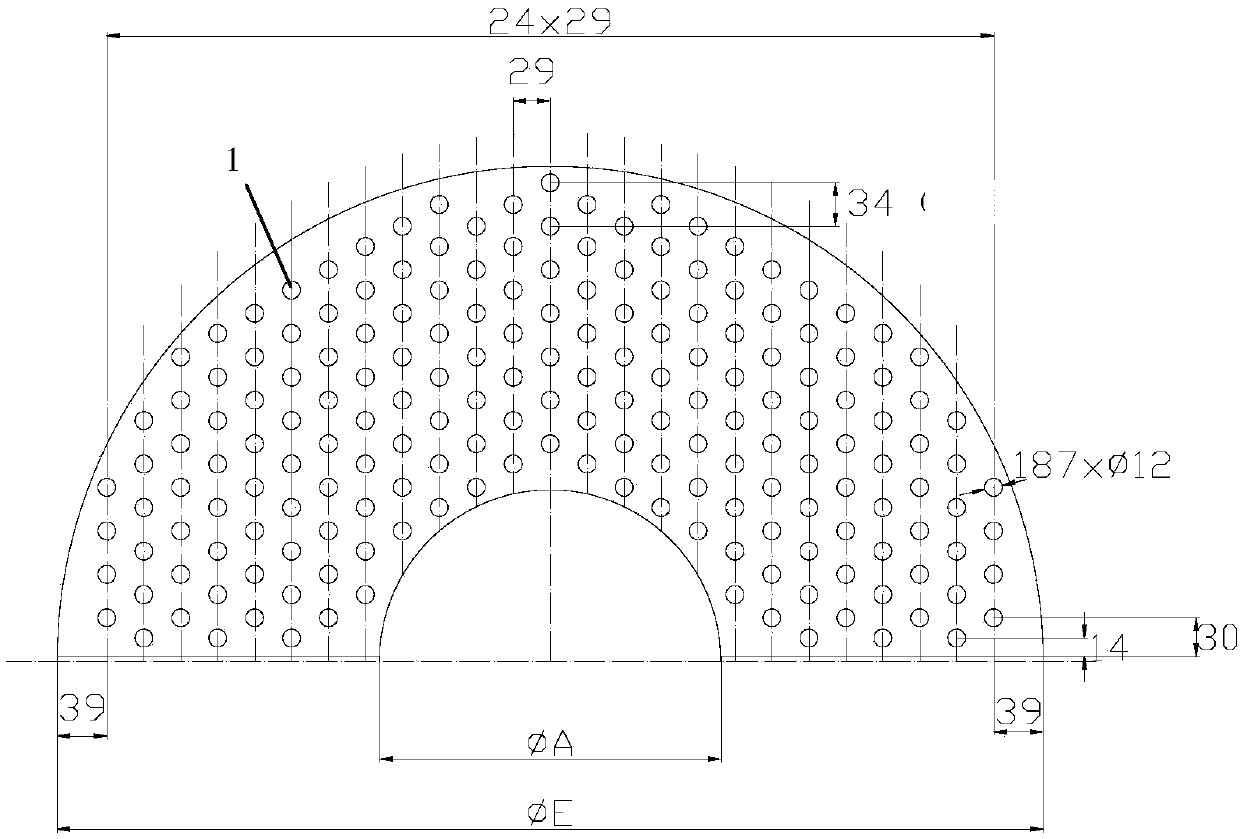

[0017] Under the function of ensuring the uniform and reasonable distribution of coke oven gas by the pure oxygen metal burner distributor, the present invention changes the slotting and wire cutting process of the prior art into the ordinary electric perforation process, which shortens the processing and manufacturing cycle and reduces the Staff technical requirements, saving production costs. That is to say, 24+20 6mm wide through slots in the prior art (such as figure 1 ) was improved to Φ12 opening, and the slotting wire cutting process was changed to the ordinary electric transfer drilling process.

[0018] see figure 2 : The pure oxygen metal burner distributor of the present invention includes a distributor main body 1, and several openings are provided in the distributor main body 1, and the openings are Φ12 openings. The distance between the centers of adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com