Front explosion-proof seat of military vehicle

A technology for military vehicles and seats, which is applied in the field of explosion-proof armored vehicles, can solve the problems of inconvenient matching and replacement of special models, inability to defend against secondary effects, and serious structural homogeneity, so as to improve reusability and prevent excessive The effect of deformation and small space requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

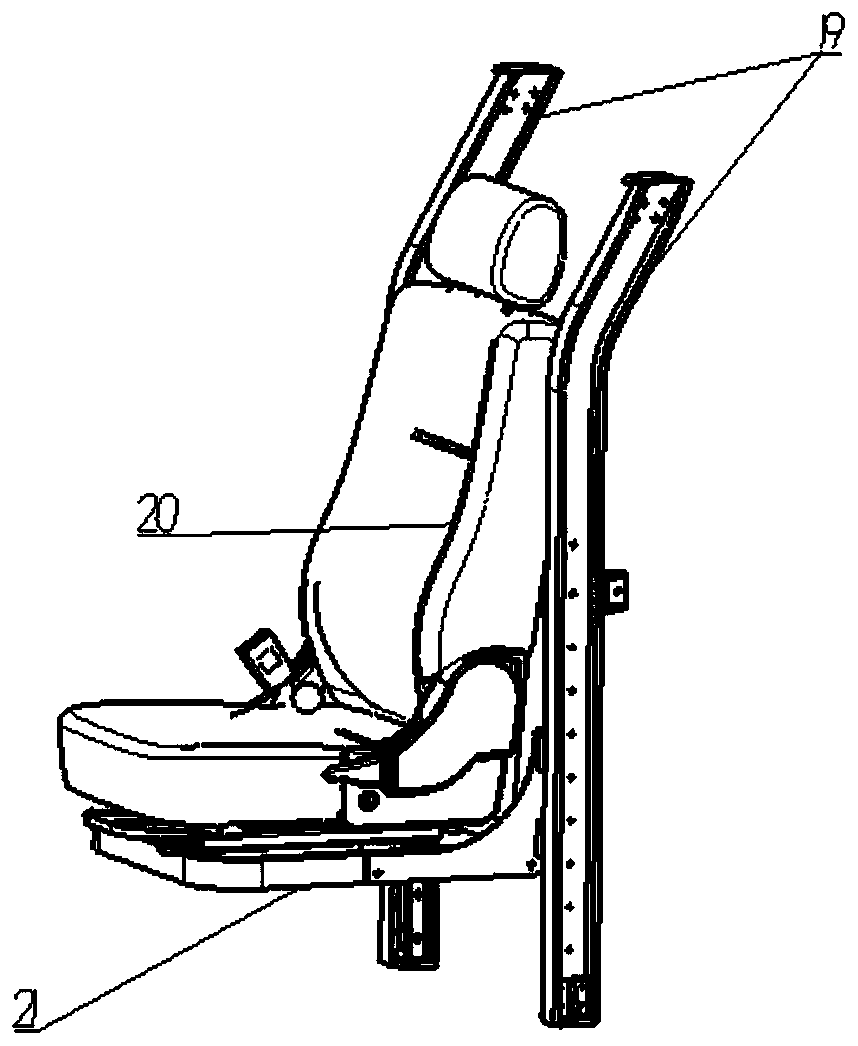

[0036] The purpose of the present invention is to reduce occupant injury in an explosive environment, thereby providing a vehicle anti-explosion seat frame, the seat cushion is installed on the frame, which can not only buffer the impact from the floor, disperse the explosion energy, improve the protective effect of the seat, but also Effectively reduce occupant injury.

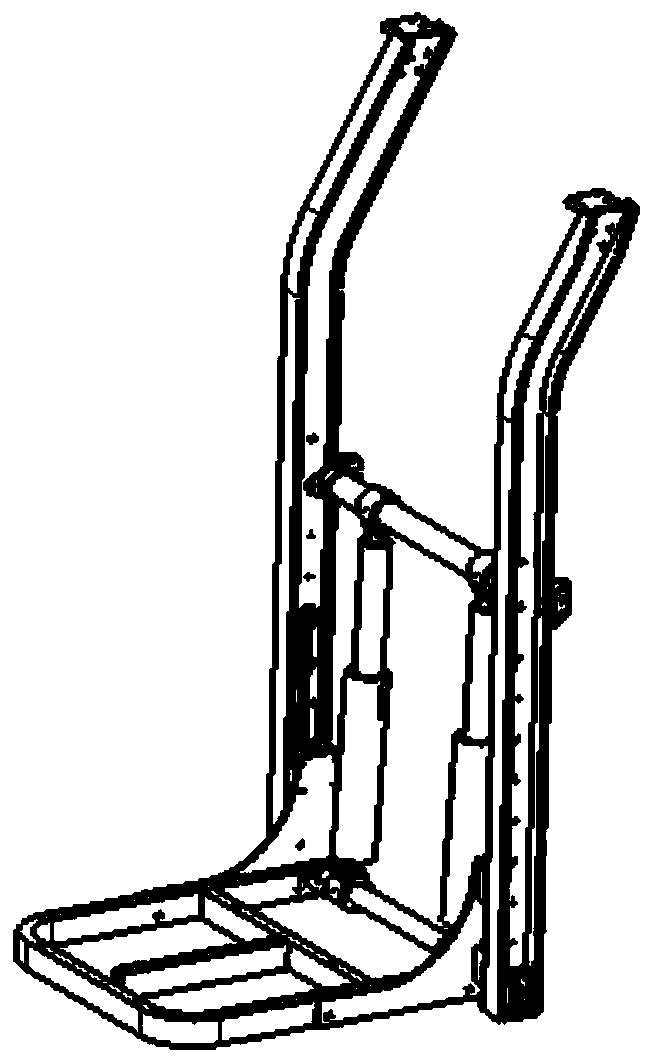

[0037] Such as image 3 As shown, the explosion-proof seat includes three parts: a fixed part 19, a movable part 21 and an energy-absorbing element 22, wherein the seat frame of the movable part 21 is installed on the sky-earth beam through the guide rail 15 and the slider 9, between which The connection is done with bolts.

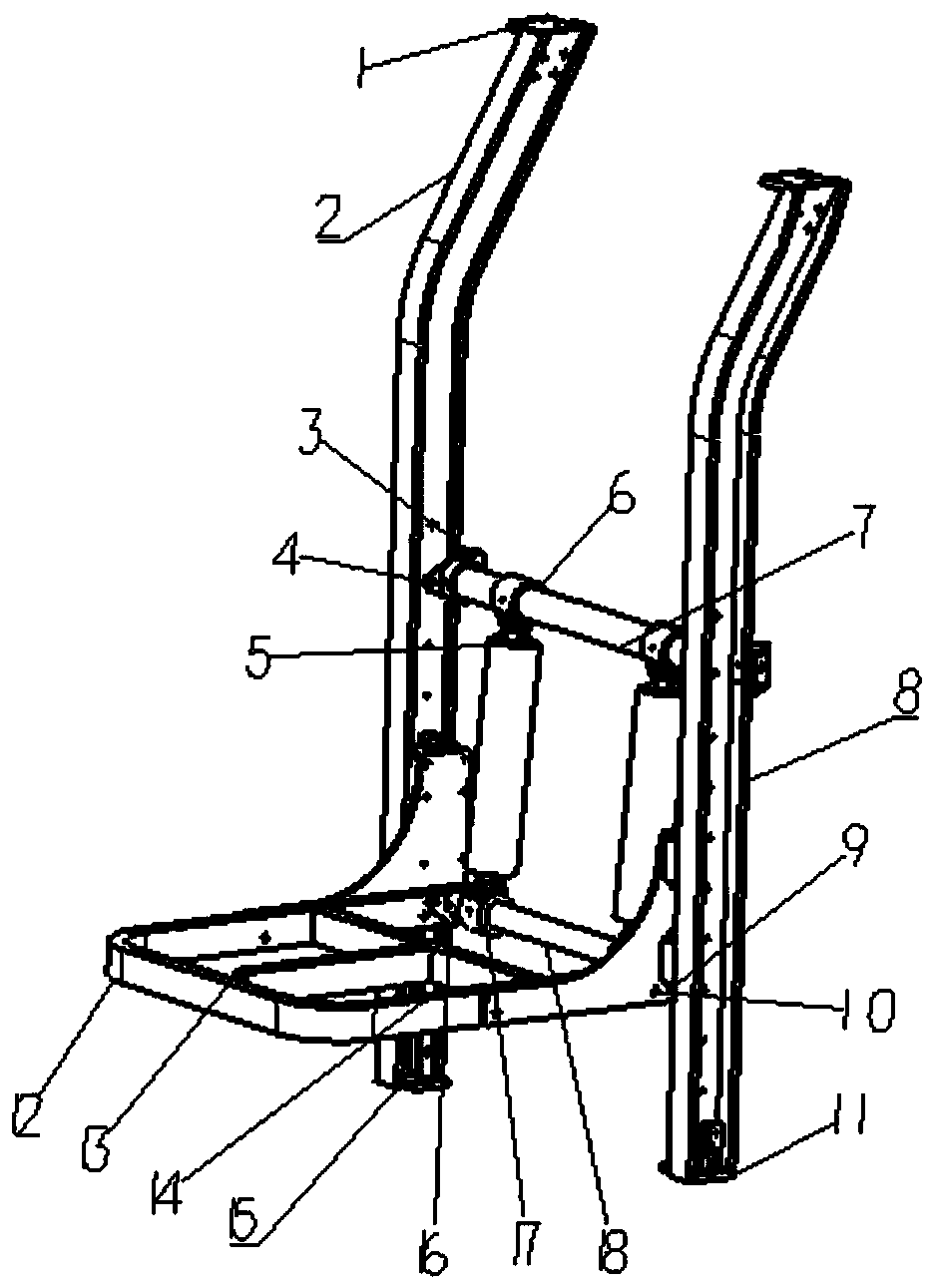

[0038] The fixed part 19 includes the upper fixing part 1 of the heaven and earth beam, the heaven and earth beam I2 and the heaven and earth beam II8, the fixing part 3 of the fixed beam, the connecting part 4 of the fixed beam, the upper connecting part 6 of the energy absorbing eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com