Two-dimensional fluid aircraft

An aircraft and fluid technology, applied in the field of aircraft, to achieve low energy consumption, improved performance, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

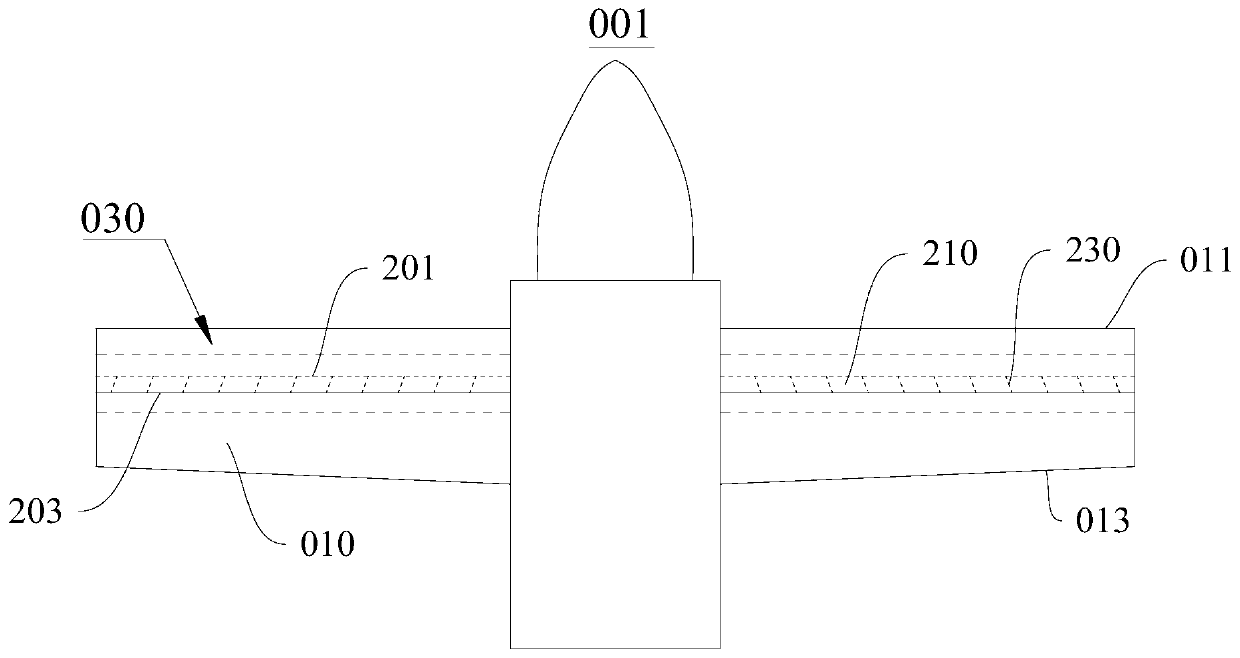

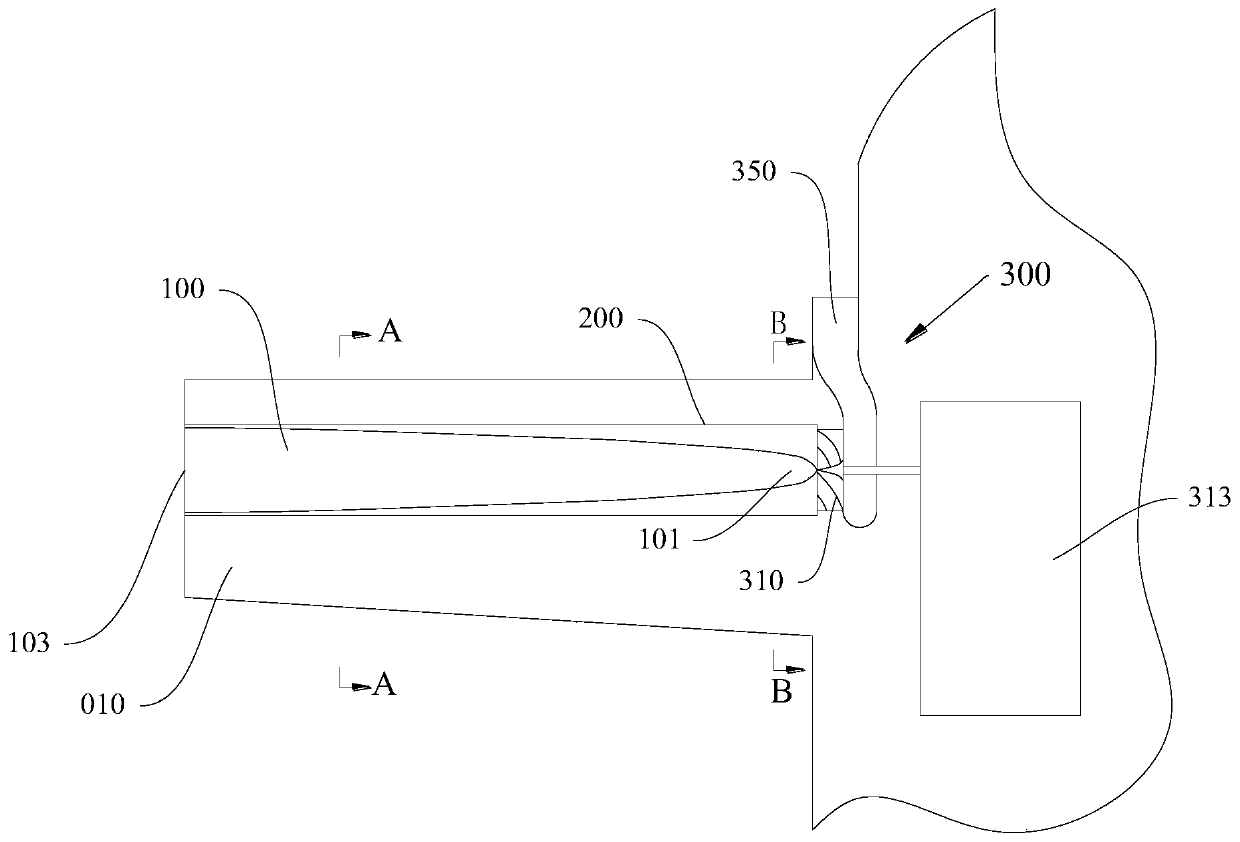

[0041] This embodiment provides a two-dimensional fluid aircraft 001, please refer to figure 1 and figure 2 , this two-dimensional fluid aircraft 001 includes wing body 010 and two-dimensional fluid converter 030; An installation space for installing the rectifying cap 100, a rectifying space is formed between the retaining wall 200 and the outer wall of the rectifying cap 100;

[0042] Retaining wall 200 conforms to the arc of equal differential diameter reduction, and has small diameter layer 201 and large diameter layer 203; The set small diameter end 101 and large diameter end 103;

[0043] The axial center of the blocking wall 200 coincides with the axial center of the rectifying cap 100; the side portion of the blocking wall 200 is formed with a rectification outlet 210 communicating with the rectification space; gap formation;

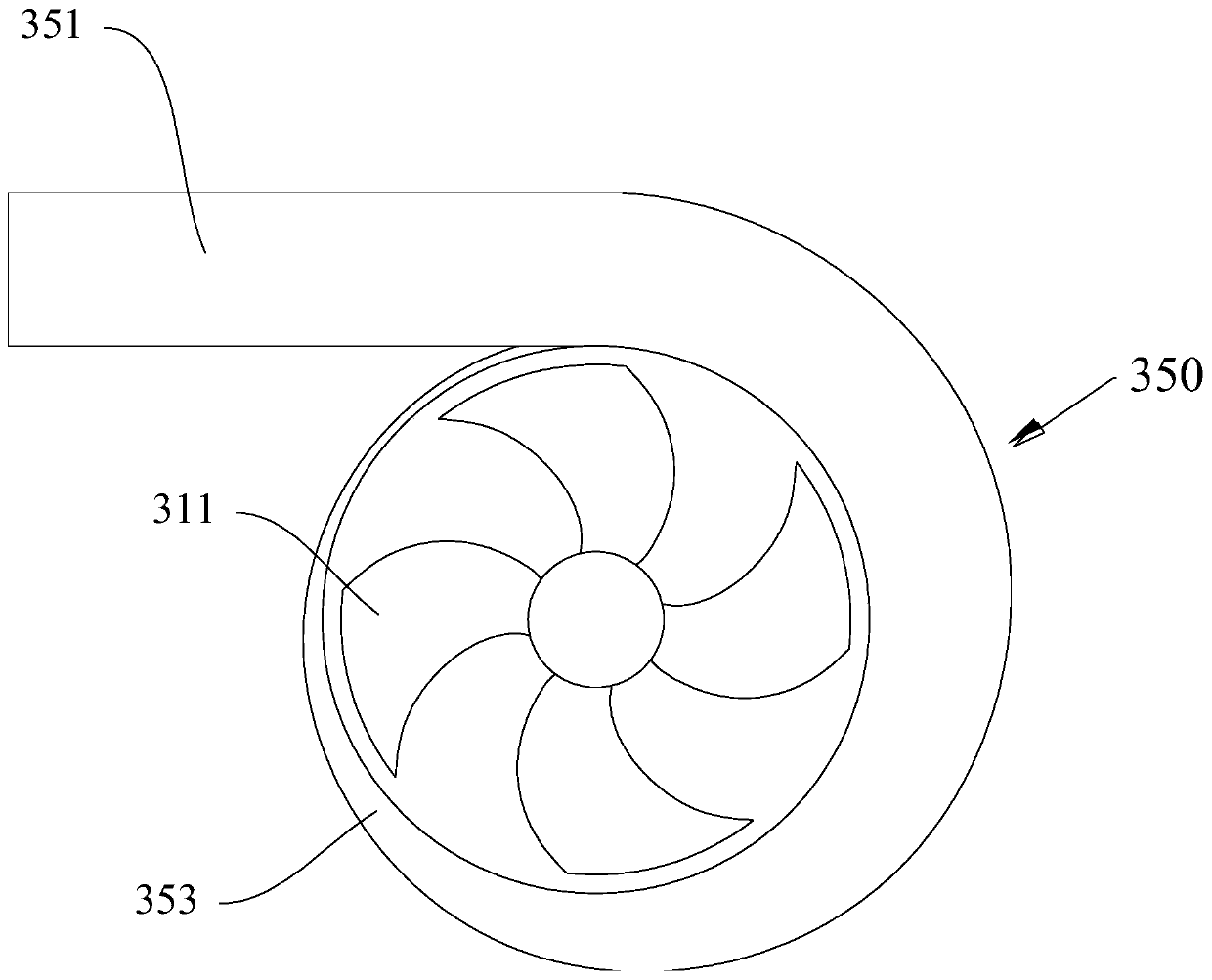

[0044] The drainage assembly 300 includes a fluid outlet, and the fluid outlet faces the small-diameter end 101 of the fairing cap 100; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com