Automatic and manual integrated three-direction stock bin rapping apparatus

A rapping device and silo technology, which is applied in the field of manual three-way hopper rapping device, can solve the problems of simple structure, unobvious blockage removal effect, and small market potential, and achieve wide adaptability and blockage removal The effect is remarkable and the effect of improving the level of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

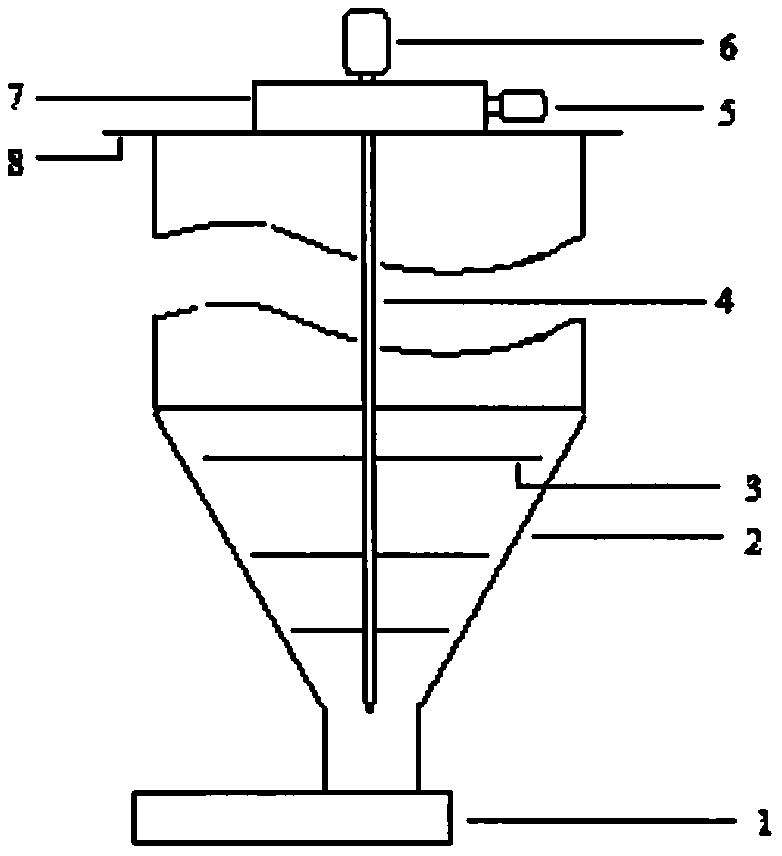

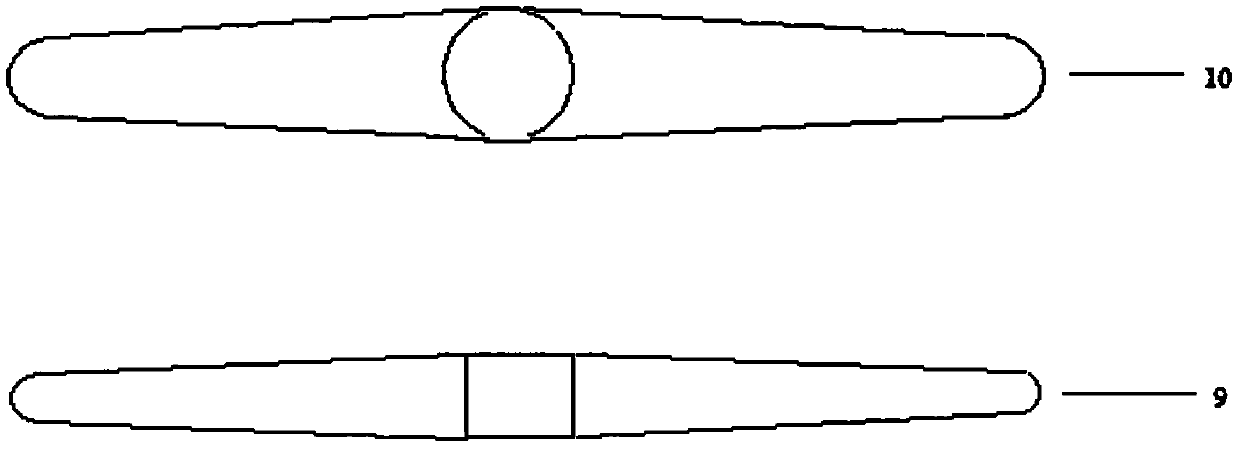

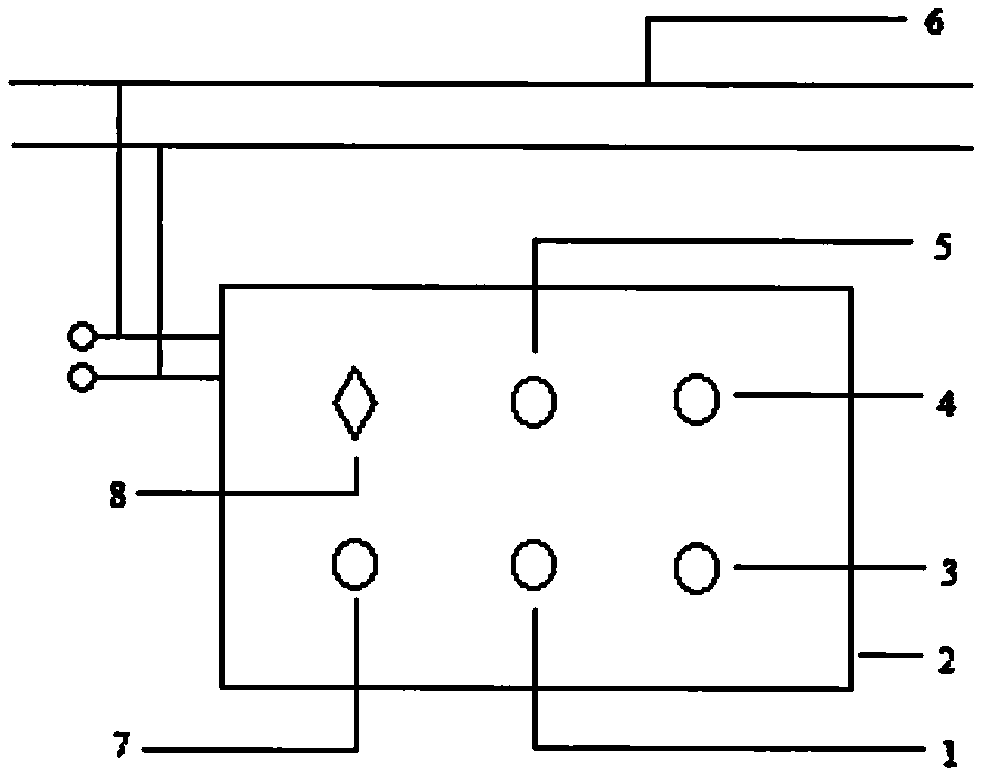

[0022] Such as figure 1 As shown, the present invention is a manual three-way bin rapping device ( figure 1 ) includes: the material falls into the coal feeder (1) through the silo (2), the vibrating fin (3) is fixed on the connecting rod (4), and the low-frequency rapping motor (6) drives the connecting rod (4) to realize low-frequency vertical vibration The low-frequency rotating motor (5) is slowed down by the reducer (7) to rotate slowly in the horizontal direction, and the low-frequency rapping motor (6) and the connecting rod (4) are fixed on the large gear inside the reducer (7) to rotate slowly at regular intervals. The silo end cover (7) is fastened to the silo (2), the side view of the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com