Preparation method of antibacterial glass

A kind of antibacterial glass and glass technology, which is applied in the direction of biocide-containing paint, decorative art, sculpture, etc., can solve the problems of limited application and unsatisfactory antibacterial effect of antibacterial glass, so as to improve the bending strength and wear resistance, excellent The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

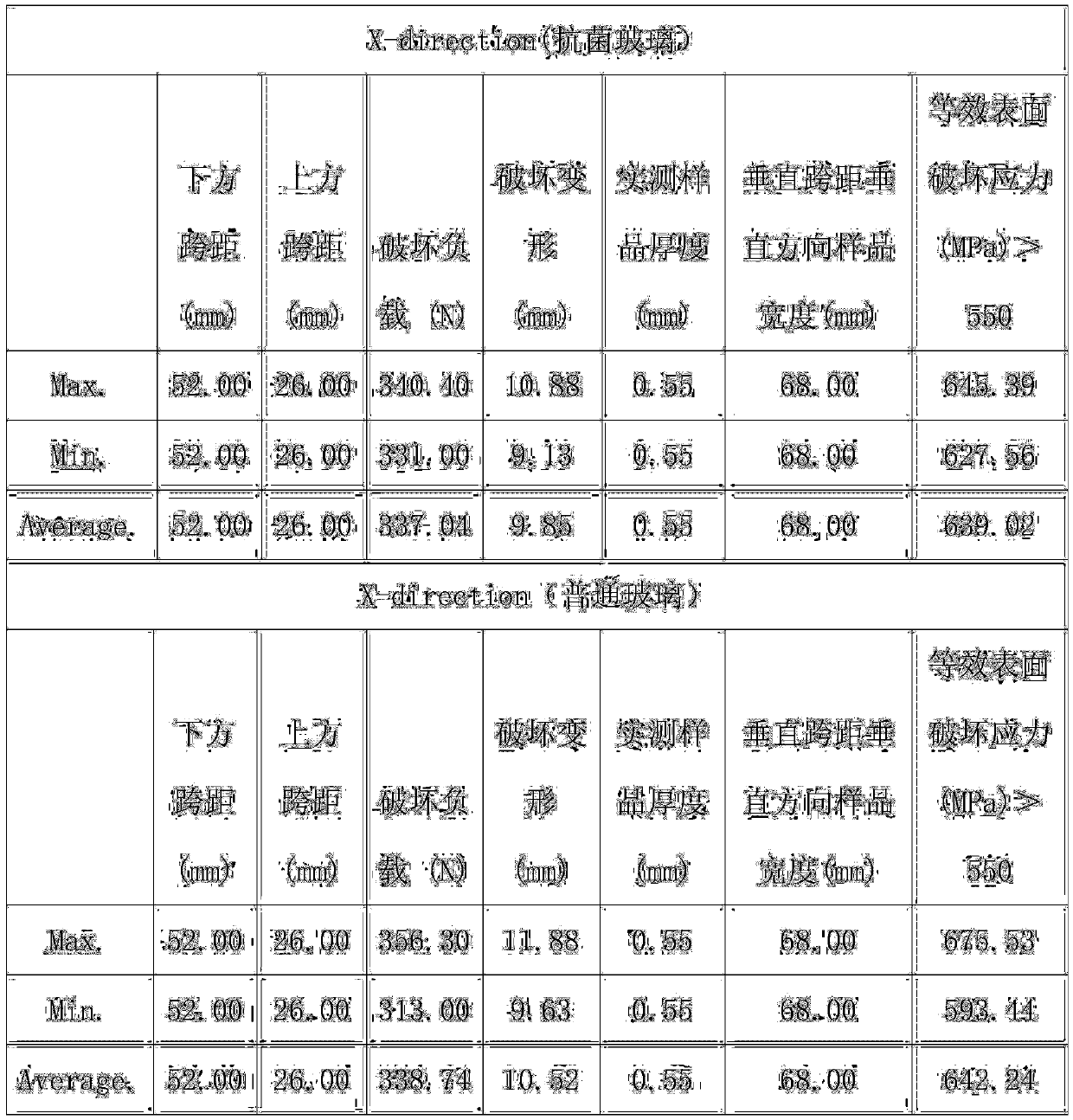

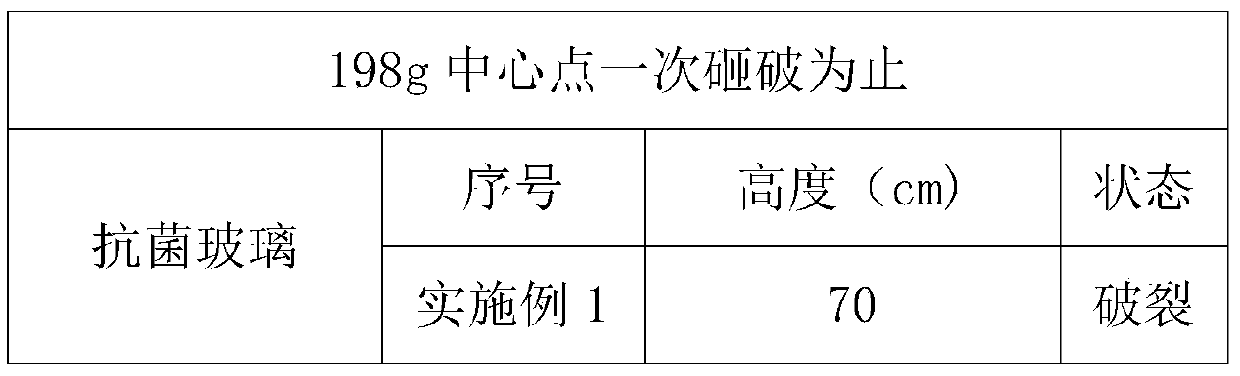

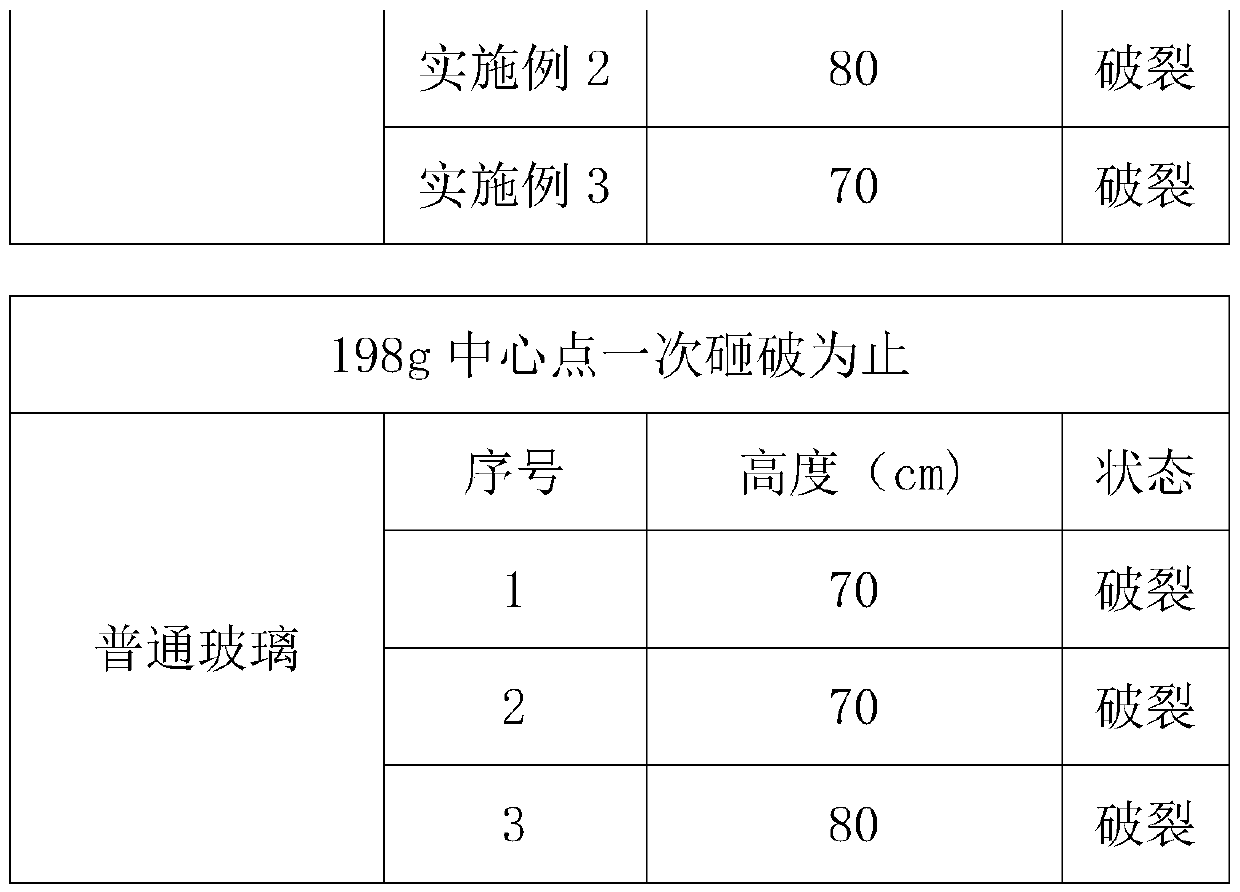

Examples

Embodiment 1

[0021] A kind of preparation method of antibacterial glass that the present invention proposes, comprises the following steps:

[0022] S1. Cut the glass raw material, then carry out fine carving processing, preheat treatment after cleaning to obtain pretreated glass;

[0023] S2, mixing potassium nitrate and silver nitrate, heating and melting to obtain antibacterial tempering furnace water, adding pretreated glass into the antibacterial tempering furnace water to perform antibacterial tempering treatment to obtain the antibacterial glass.

Embodiment 2

[0025] A kind of preparation method of antibacterial glass that the present invention proposes, comprises the following steps:

[0026] S1. Cut the glass raw material, then carry out fine carving processing, preheat treatment after cleaning to obtain pretreated glass;

[0027] S2, mixing potassium nitrate and silver nitrate, heating and melting to obtain antibacterial tempering furnace water, adding the pretreated glass to the antibacterial tempering furnace water for antibacterial tempering treatment to obtain the antibacterial glass;

[0028] Wherein, in S1, the temperature of the preheating treatment is 340° C., and the time is 3 hours;

[0029] In S2, the weight ratio of potassium nitrate to silver nitrate is 80:0.35;

[0030] In S2, the purity of the potassium nitrate is 99.8wt%; the silver nitrate is analytically pure silver nitrate;

[0031] In S2, the temperature of the antibacterial tempering treatment is 370° C., and the time is 2 hours.

Embodiment 3

[0033] A kind of preparation method of antibacterial glass that the present invention proposes, comprises the following steps:

[0034] S1. Cut the glass raw material, then carry out fine carving processing, preheat treatment after cleaning to obtain pretreated glass;

[0035] S2, mixing potassium nitrate and silver nitrate, heating and melting to obtain antibacterial tempering furnace water, adding the pretreated glass to the antibacterial tempering furnace water for antibacterial tempering treatment to obtain the antibacterial glass;

[0036] Wherein, in S1, the temperature of the preheating treatment is 380°C, and the time is 1h;

[0037] In S2, the weight ratio of potassium nitrate to silver nitrate is 70:0.4;

[0038] In S2, the purity of the potassium nitrate is 99.8wt%; the silver nitrate is analytically pure silver nitrate;

[0039] In S2, the temperature of the antibacterial tempering treatment is 420°C, and the time is 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com