A kind of preparation method of antibacterial glass

A kind of antibacterial glass and glass technology, which is applied in the direction of paint, engraving, coating, etc. containing biocide, and can solve the problems of unsatisfactory antibacterial effect and limited application of antibacterial glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

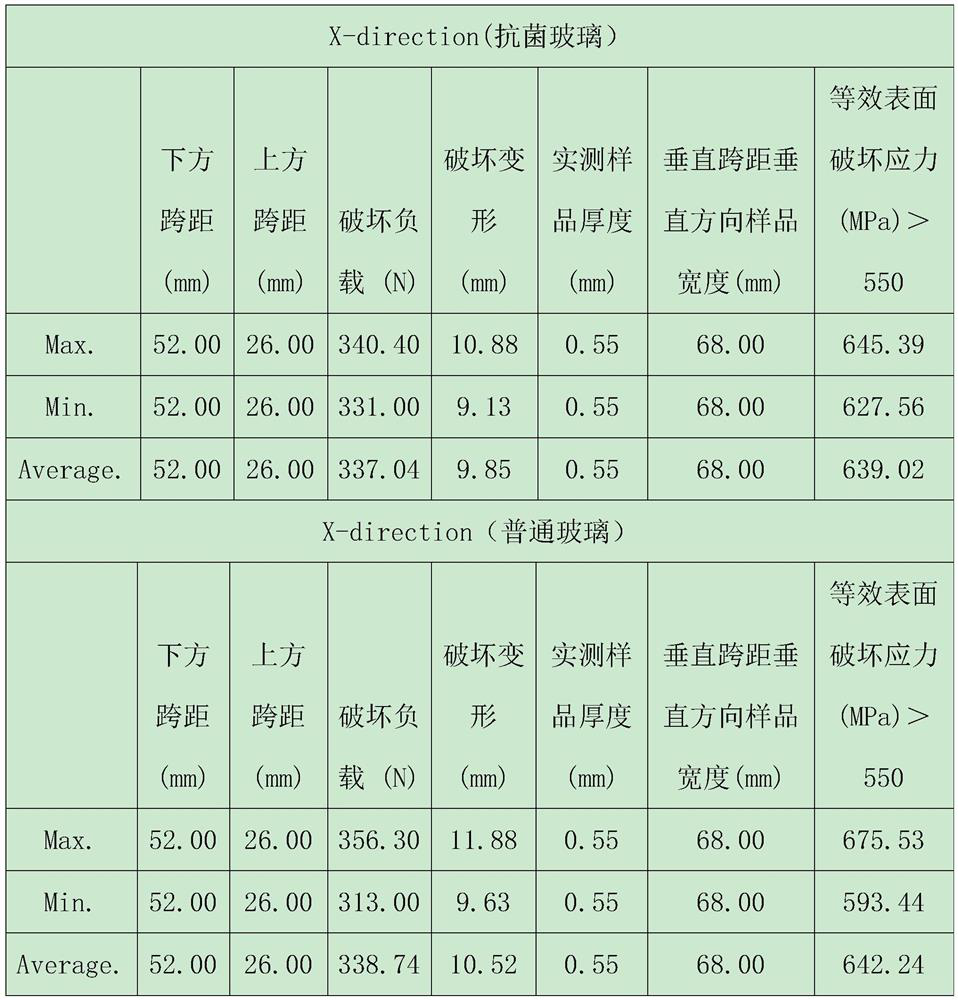

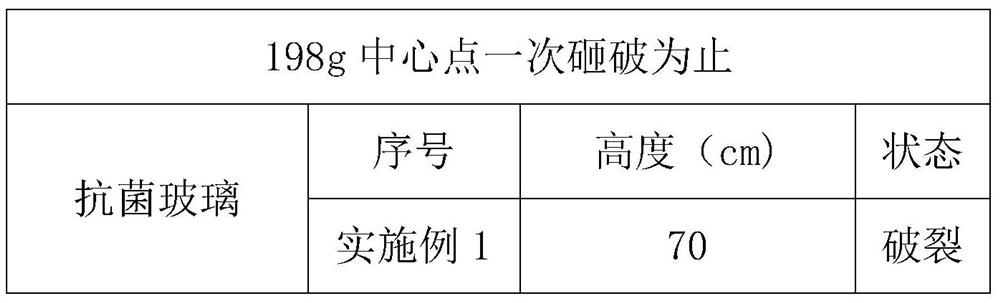

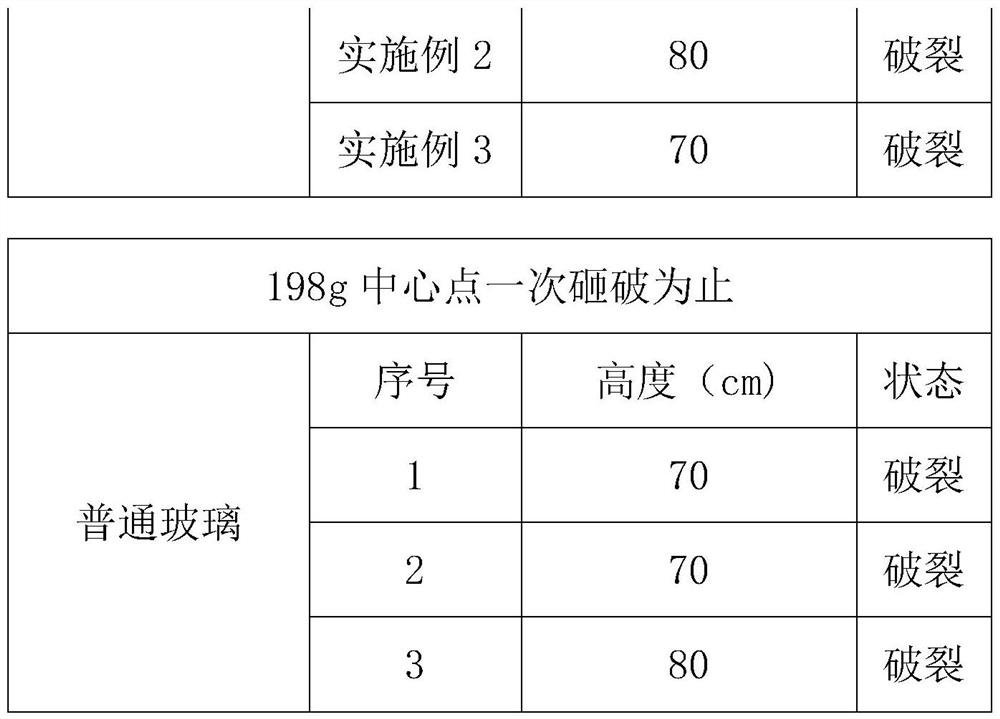

Examples

Embodiment 1

[0021] A method of preparation of antibacterial glass proposed by the present invention includes the following steps:

[0022] S1, cut the glass raw material, then carry out the process, and preprocessing the pretreatment glass after cleaning;

[0023] S2, after mixing the potassium nitrate and silver nitrate, heat the antibacterial temperature furnace water, and the pretreatment glass is added to the antibacterial temperatures in the antibacterial temperatures to obtain the antibacterial glass.

Embodiment 2

[0025] A method of preparation of antibacterial glass proposed by the present invention includes the following steps:

[0026] S1, cut the glass raw material, then carry out the process, and preprocessing the pretreatment glass after cleaning;

[0027] S2, after mixing the potassium nitrate and silver nitrate to heat the antibacterial temperatured furnace water, the pretreatment glass is added to the antibacterial temperatures in the antibacterial tempered treatment to obtain the antibacterial glass;

[0028] Among them, in S1, the temperature of the preheating treatment is 340 ° C, and the time is 3 h;

[0029] In S2, the weight ratio of potassium nitrate and silver nitrate is 80: 0.35;

[0030] In S2, the purity of the potassium nitrate is 99.8 wt%; silver nitrate is silver nitric acid;

[0031] In S2, the temperature of the antibacterial tempered treatment is 370 ° C, and the time is 2 h.

Embodiment 3

[0033] A method of preparation of antibacterial glass proposed by the present invention includes the following steps:

[0034] S1, cut the glass raw material, then carry out the process, and preprocessing the pretreatment glass after cleaning;

[0035] S2, after mixing the potassium nitrate and silver nitrate to heat the antibacterial temperatured furnace water, the pretreatment glass is added to the antibacterial temperatures in the antibacterial tempered treatment to obtain the antibacterial glass;

[0036] Among them, in S1, the temperature of the preheating treatment is 380 ° C, and the time is 1 h;

[0037] In S2, the weight ratio of potassium nitrate and silver nitrate is 70: 0.4;

[0038] In S2, the purity of the potassium nitrate is 99.8 wt%; silver nitrate is silver nitric acid;

[0039] In S2, the temperature of the antibacterial tempered treatment is 420 ° C, and the time is 0.5 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com