Solar heat collecting tube structure with external getter device

A technology of solar collector tubes and getters, applied to solar collectors, solar collectors using working fluids, solar collector safety, etc., can solve problems such as failure and high temperature of getters, and achieve production costs Low cost, low processing cost, and the effect of improving vacuum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

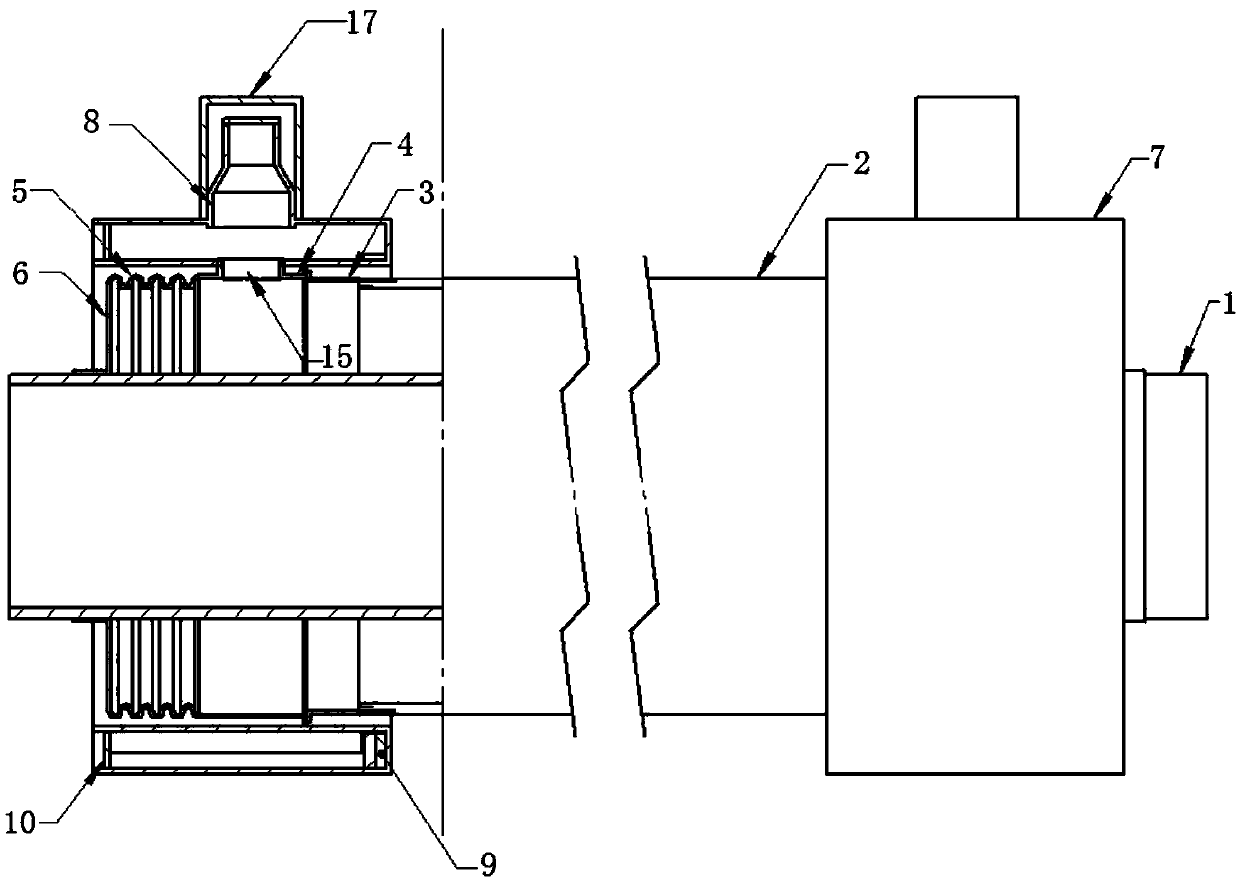

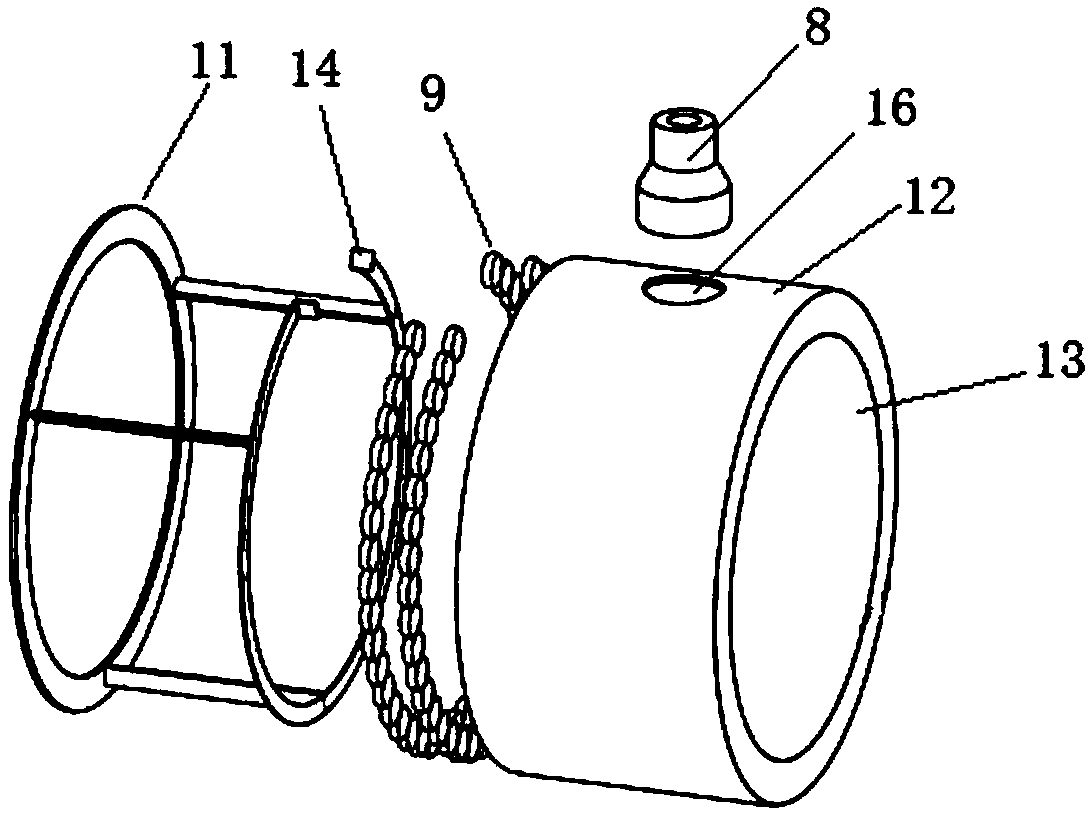

[0028] Such as figure 1 As shown, the heat collecting tube structure provided by the present invention includes coaxially arranged stainless steel tube 1 and glass tube 2, the stainless steel tube 1 is used as the inner tube of the heat collecting tube, and the glass tube 2 is used as the outer tube of the heat collecting tube. The two ends of the glass tube 2 are respectively symmetrically connected to the coaxial Kovar ring 3 through glass-metal fusion seals along the axial direction. The outer end of the Kovar ring 3 is connected with the stainless steel joint 4 by welding. The bellows 5 is used as the elastic expansion joint, and the bellows 5 is welded to the outer end of the stainless steel joint 4 . The outer side of the stainless steel ring 6 is welded with the bellows 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com