Vehicle stand test system and method

A bench test and vehicle technology, which is applied to the vehicle bench test system and its test field, to achieve the effects of reducing wear, improving safety, and shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

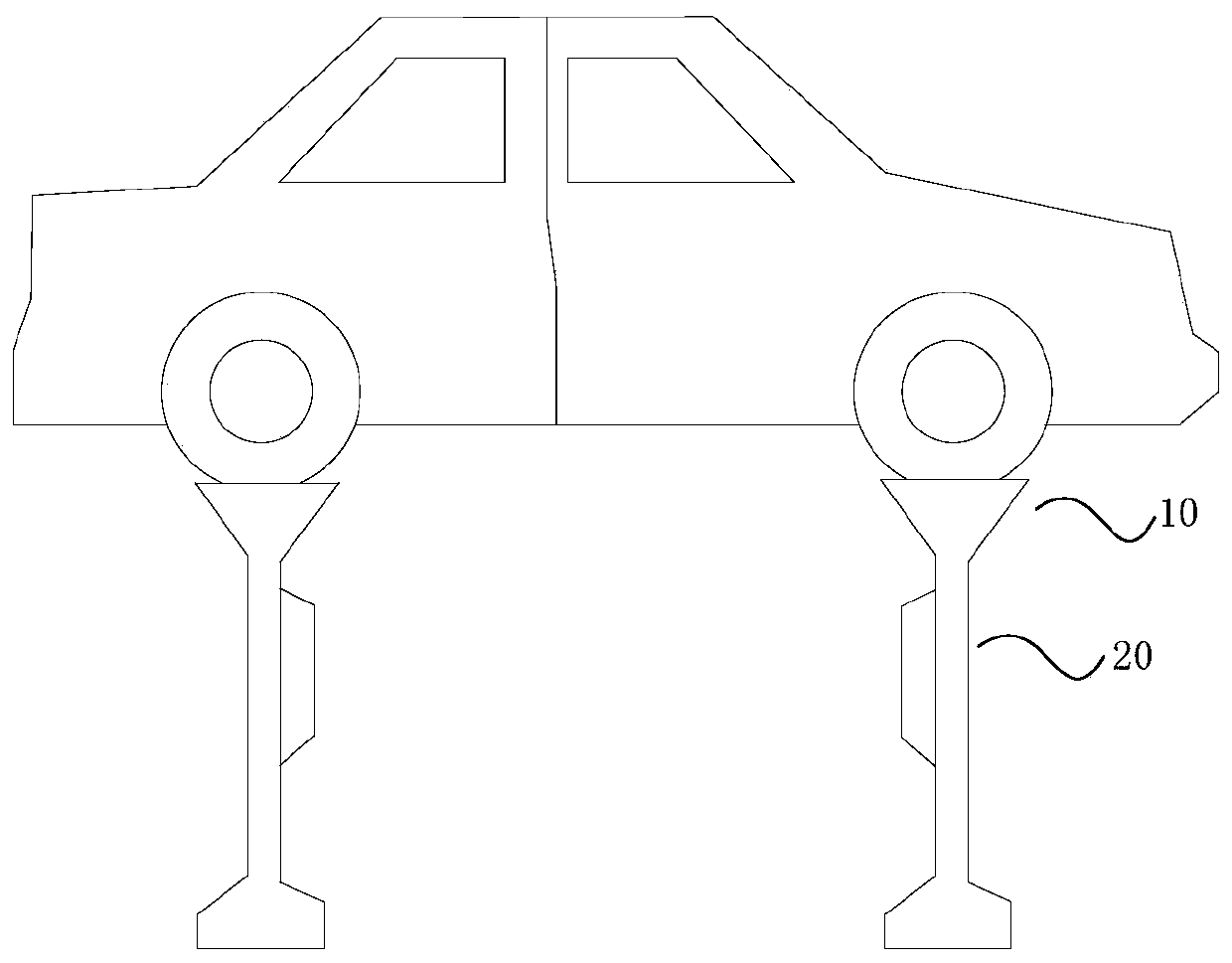

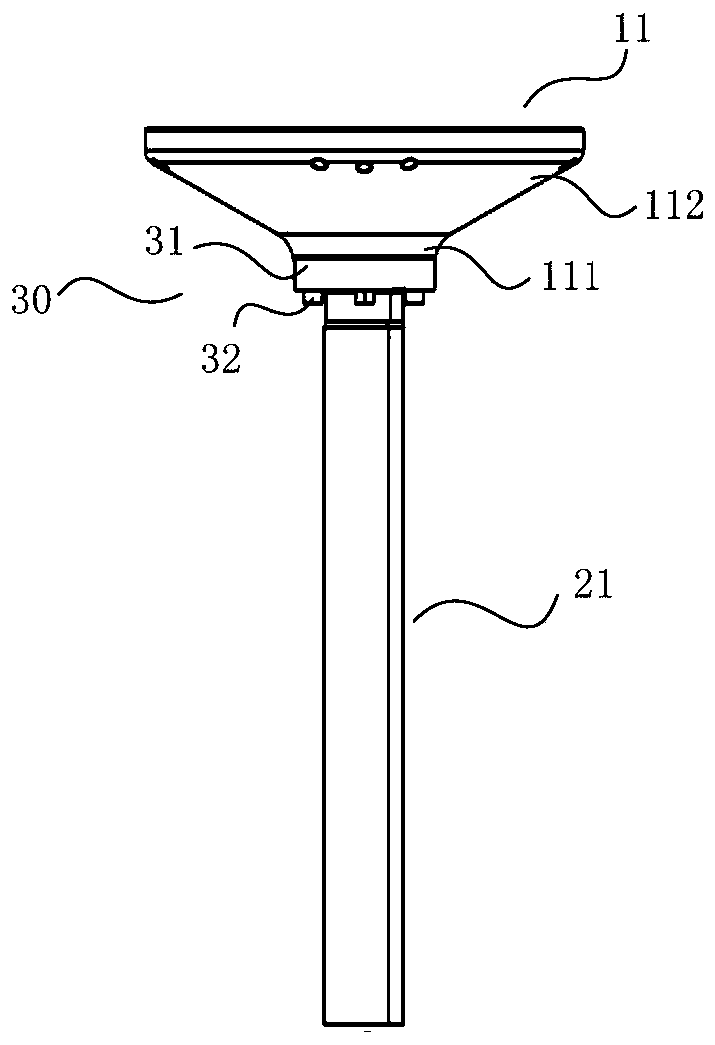

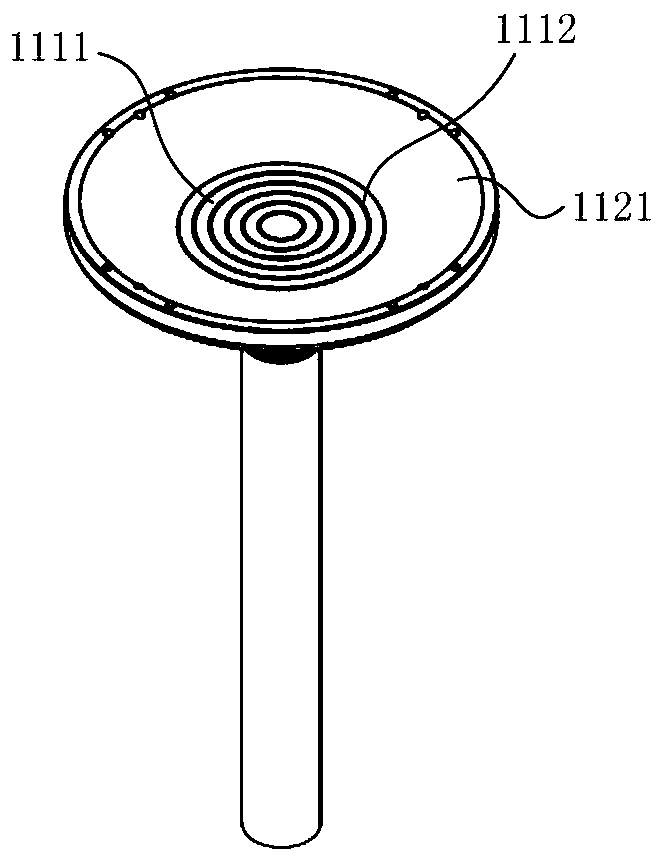

[0053] See Figure 1-4 This embodiment provides a vehicle bench test system, which includes an excitation mechanism 20 and a bearing mechanism 10.

[0054] Wherein, the excitation mechanism 20 includes an actuator 21 for generating excitation, and the actuator can be adjusted accordingly according to the test items of the vehicle bench test. For example, if the road simulation fatigue test of a test vehicle is performed, the road spectrum can be input to the actuator to simulate actual road conditions, and the actuator can be controlled to directly or indirectly generate a vertical upward excitation and install it on the vehicle to be tested. Carry out road simulation test. Of course, if the torsion test of the vehicle is tested, the actuator can be controlled to generate excitation in the corresponding direction and installed on the vehicle to be tested to perform the corresponding performance test. The actuator may be a hydraulic cylinder. Of course, the hydraulic cylinder ca...

Embodiment 2

[0078] Figure 5 It is a schematic structural diagram of a vehicle bench test system during a test process according to another embodiment of the present invention. Such as Figure 5 As shown, unlike Embodiment 1, this embodiment provides a vehicle bench test system, which further includes a displacement detection device 40 and a test controller.

[0079] Wherein, the displacement detection device 40 is connected to the body of the vehicle to be tested, and is used to detect the offset of the vehicle to be tested in the horizontal direction. The test controller is connected with the actuator, and is used to control the actuator to stop providing excitation if it is judged that the received offset exceeds the preset protection interval.

[0080] By setting the displacement detection device 40, the offset under each test condition can be monitored in real time. If the detected offset of the vehicle exceeds the preset protection interval, the actuator can be controlled to quickly stop...

Embodiment 3

[0092] This embodiment also provides a vehicle bench test method, which adopts the test system of embodiment 2 and includes at least the following steps:

[0093] Park the vehicle to be tested on the pallet;

[0094] Fix the test end of the displacement sensor on the body of the vehicle to be tested in the horizontal direction, and connect the other end to the fixed seat and the data acquisition line of the data acquisition instrument respectively to calibrate the sensor coefficient;

[0095] Connect the data collector to the controller and input the sensor calibration coefficient;

[0096] Set the channel path and program protection value interval of the sensor;

[0097] Start the road spectrum iteration and durability test of the vehicle, and use the response signal of the displacement sensor collected during the period as the protection target;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com