Band-type automatic net-changing device and drip irrigation zone producing method using band-type automatic net-changing device

A technology of automatic screen changing and heating device, which is applied in the field of belt automatic screen changing device and the drip irrigation belt formed by using it, can solve the problem of pulling off; Chinese patent was announced on May 4, 2011, the efficiency of changing the screen is low, The mesh belt is broken and other problems, so as to achieve the effect of easy automatic control, power saving and power demand reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

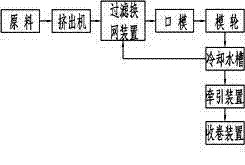

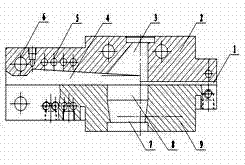

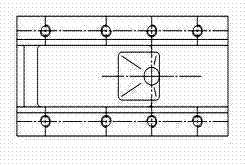

[0034] Refer to attached figure 1, Embodiment 1: a mesh belt type automatic screen changing device, including a screen changing plate 2 and a fixed plate 9 and the two are movably connected and form a sealing channel for the mesh belt to pass through at the joint, the screen changing plate and the fixed plate A heating device 6 and a cooling device 5 are provided, a pressure sensor is also provided on the screen changer, a discharge channel 7 communicating with the sealing channel 4 is provided on the fixed plate, a perforated plate 8 is provided at the outlet of the discharge channel, and the fixed plate Connect the die, and the screen changer is provided with a feed channel that communicates with the sealing channel and generates lateral force along the direction of the sealing channel. The feed channel is a special-shaped round structure, and the side of the feed channel connected to the extruder It is a circular mouth, and the other side is a square mouth. A bus line on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com