Surface modification method of aramid fibers

A technology of aramid fiber and surface modification, which is applied in fiber type, fiber treatment, textile and papermaking, etc., and can solve problems such as performance degradation, rubber molecular weight decrease, and excessive fiber length reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0026] Cut the aramid filament (brand: AF-1000, 1500 denier, Korea ALKEX company) into 20mm sections, clean the aramid fiber with acetone ultrasonically for 1 hour, and then dry it to remove the organic coating attached to its surface;

[0027] S1: Unwind the aramid raw yarn smoothly with a pay-off rack, keeping it from loosening and twisting;

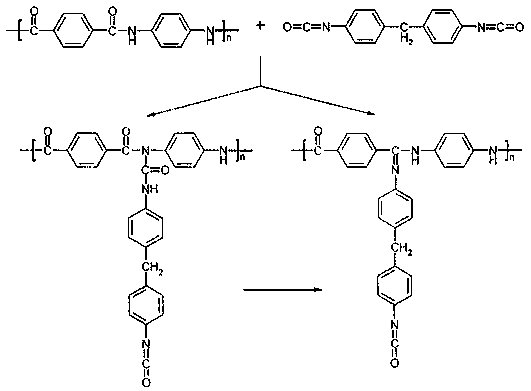

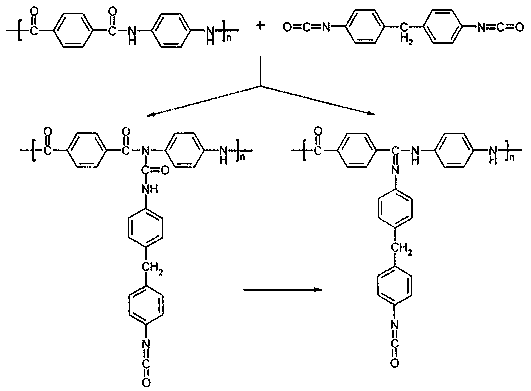

[0028] S2: Reach the first group of drafting rollers through the splitting comb, and enter the first glue tank through the guide roller for a bath; the first bath uses phenol-blocked polyisocyanate, which specifically includes step 1: impregnating with isocyanate at a temperature of 50-15 °C Wash and dry the aramid fiber for 1-3 hours; step 2: impregnate the aramid fiber with an acetone solution of epoxy resin with a mass percentage concentration of 6-18% at room temperature for 2.5-4 hours, and complete after drying Surface modification of aramid fibers.

[0029] S3: enter the first layer of oven for drying, the drying temperature is...

experiment example 2

[0035] Under the same experimental conditions, steps S1-S8 of comparative experimental example 1 were not subjected to any treatment.

[0036] Comparative Experiment:

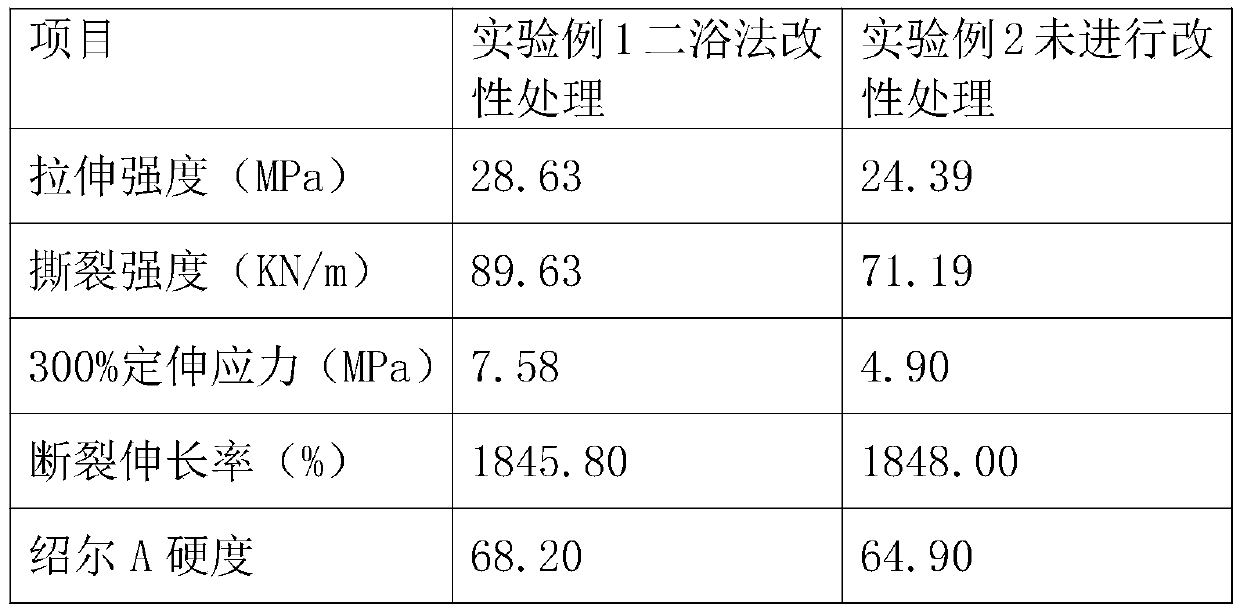

[0037] Take by weighing 40 grams of aramid staple fibers obtained in Experimental Examples 1, 2, and 3 respectively, and mix with 1000 grams of natural rubber, 17 grams of sulfur vulcanizing agent and 10 grams of compounding agent; compounding agent includes 30 grams of zinc oxide, 20 grams of stearin Acid, 17.1 grams of accelerator M, 14.7 grams of accelerator DM, 5 grams of accelerator D, 3.2 grams of accelerator TMTD and 10 grams of anti-aging agent SP-C.

[0038] Mix them in an internal mixer at 120°C for 10 minutes at a speed of 80r / min, then mix them on a double-roll mill at 60°C, add 17g of sulfur vulcanizing agent and 100g of compounding agent, and pass it 4 times. The mixed rubber is obtained; the mixed rubber is vulcanized at 145° C. according to the positive curing time tc90 measured by a vulcanizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com