Modified aramid short fiber flame-retardant thermoplastic plastic plate

A thermoplastic, modified aramid fiber technology, applied in the direction of fiber type, fiber processing, sheet/board, etc., can solve the problems of inconvenient transportation, inconvenience for users, lack of disassembly and assembly, and meet the requirements of adhesion enhancement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] A modified aramid short fiber flame retardant thermoplastic board. The raw materials of the modified aramid short fiber flame retardant thermoplastic board are composed of thermoplastics and modified aramid short fiber flame retardant. The above-mentioned thermoplastic is 94.3%, and the modified aramid staple fiber flame retardant is 5.7%;

[0045] The raw material preparation method of the flame-retardant thermoplastic is:

[0046] The temperature of the internal mixer is controlled at 168°C, and the rotational speed is 550 rpm, and the thermoplastic is added to the internal mixer, and the additive flame retardant is added after it is melted, and melted and blended for 12 minutes to obtain a flame-retardant thermoplastic material. Place it in an environment of 25°C and a relative humidity of 60% for 60 hours to form;

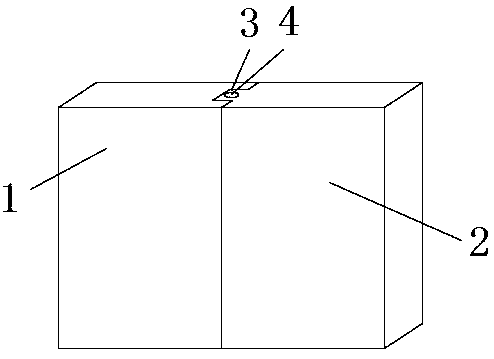

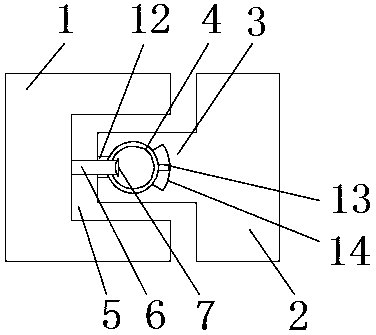

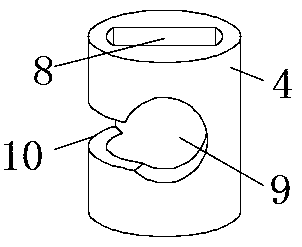

[0047] The material is pressed into a plate body, the plate body includes a first plate body 1, a second plate body 2 is movably connected to one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com