Preparation method for aramid fiber composite rubber pipeline

A technology of aramid fiber and composite rubber, which is applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of rubber molecular weight drop, excessive fiber length reduction, and lack of composite rubber hose materials, etc., to achieve puncture resistance and anti-corrosion The effect of improving the tensile capacity and improving the tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

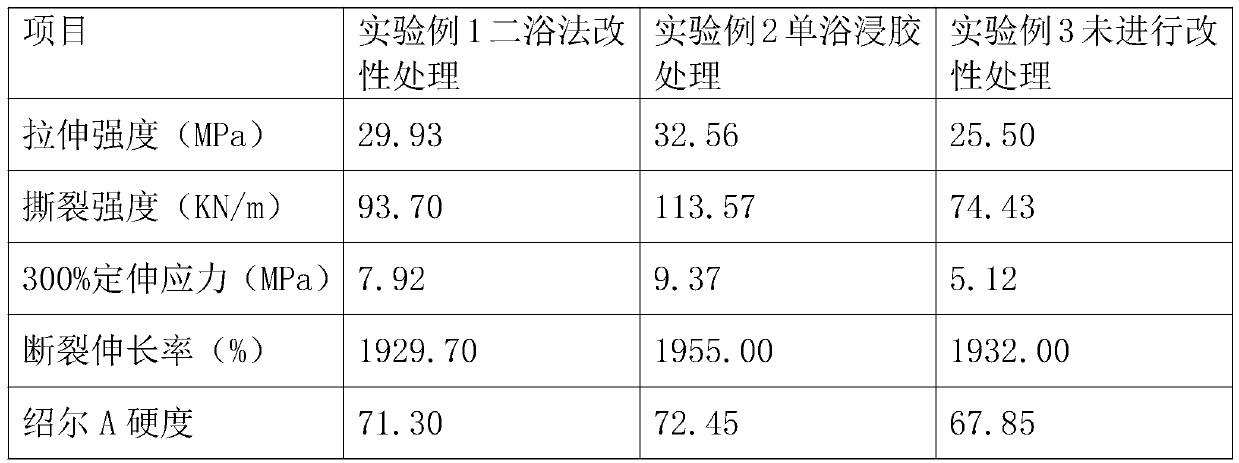

Examples

preparation example Construction

[0056] A preparation method for an aramid fiber composite rubber pipeline, comprising the steps of:

[0057] (1) Modification of aramid fibers;

[0058] (2) Mixed rubber processing

[0059] (3) Forming

[0060] (4) vulcanization;

[0061] Wherein, the specific steps in step one are as follows:

[0062] It includes the following processing steps for aramid raw silk: A: first bath; B: first drying; C: second bath; D: second drying; E: winding; F: cutting; wherein: the steps In A, the water-solvent type highly reactive isocyanate is used for pre-impregnation; in step C, the RFL impregnation solution is used for impregnation, and the formula of the RFL impregnation solution is: RF resin: 420.6 parts by weight; soft water: 95.2 parts by weight; VP Latex 40%: 484.2 parts by weight; Wherein the formula of RF resin is: Soft water: 425.6 parts by weight; Sodium hydroxide 7%: 16 parts by weight; Resorcinol solid: 22 parts by weight; Formaldehyde 38%: 13 parts by weight;

[0063] I...

Embodiment 1

[0072] Embodiment 1: RF resin solution deployment;

[0073] (1) prepare soft water, the resorcinol solid of 22 parts by weight and the formaldehyde 38% of 13 parts by weight;

[0074] (2) Put soft water in the reaction tank, and the water temperature is controlled at 23°C;

[0075] (3) Sodium hydroxide is dissolved in demineralized water, and after being mixed with the aqueous sodium hydroxide solution of 7%, put in the reaction tank, the aqueous sodium hydroxide solution is 16 parts by weight, and stirs and mixes for 10 minutes;

[0076] (4) resorcinol solid is dissolved in demineralized water, is mixed with the resorcinol solution of concentration 10~20% and puts in the reaction tank after, and stirs and mixes 20 minutes;

[0077] (5) Put 38% of formaldehyde into soft water and mix to prepare a formaldehyde solution with a concentration of 5-20%, slowly add the formaldehyde solution into the reaction tank, and continue to stir the reaction tank;

[0078] (6) Cool the react...

Embodiment 2

[0079] Embodiment 2: the deployment of RFL dipping solution;

[0080] One, prepare the RF resin liquid of 420.6 parts by weight, the soft water of 95.2 parts by weight and the VP latex 40% of 484.2 parts by weight, total weight part 1000;

[0081] 2. Put soft water and VP latex into the blending tank;

[0082] 3. Transfer the RF resin liquid to the blending tank and keep stirring. The transfer of the RF resin liquid is completed within 10 minutes. The RF resin liquid is transferred by spraying. The temperature of the glue solution is 20°C, and the pH value is adjusted to between 8-9;

[0083] 4. From the transfer of RF resin, after 27 hours of aging, the obtained RFL impregnation solution is sent to the subsequent impregnation machine for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com