A kind of air drilling roller cone bit device

A technology of roller cone bit and air drill, which is applied to drill bit, driving device for drilling in wellbore, earth-moving drilling, etc. Problems such as short life and restricting the well formation speed of hot dry rock development can improve the rock breaking efficiency, enhance the rock breaking effect and prolong the working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is introduced below by accompanying drawing.

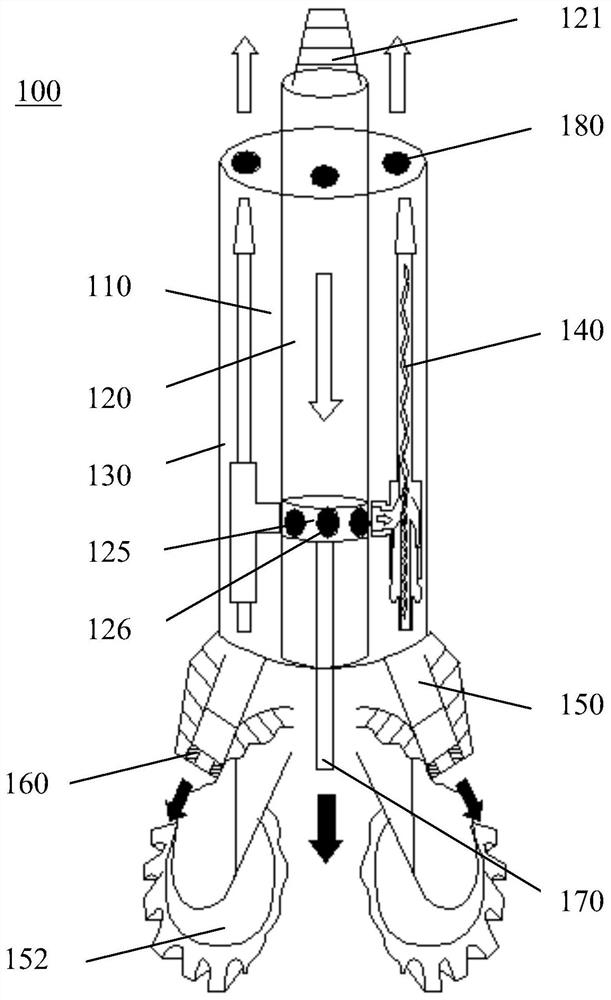

[0022] figure 1 The structure of an air drilling roller cone bit device 100 for developing hot dry rock according to the present invention is shown. Such as figure 1 As shown, the air drilling roller cone bit device 100 is generally in a cylindrical structure as a whole. The air roller cone bit assembly 100 includes an inner barrel 120 for receiving high pressure air. The inner cylinder 120 is configured as a cylindrical structure, and the upstream end of the inner cylinder 120 is provided with a connecting portion 121, which is preferably a connecting thread. Thus, the air drilling roller cone bit device 100 is connected with other downhole drilling tools through connecting threads. The threaded connection structure of the inner cylinder 120 makes the installation and connection of the air drill roller cone bit device 100 very convenient and fast.

[0023] In this application, when the air-drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com