Flange assembly of sterile glove

A glove and flange technology, which is applied in the field of flange components of sterile gloves, can solve the problems of inability to test glove integrity, prolong the production cycle, and flanges that cannot be used universally, so as to reduce procurement costs, increase production batches, and achieve versatility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

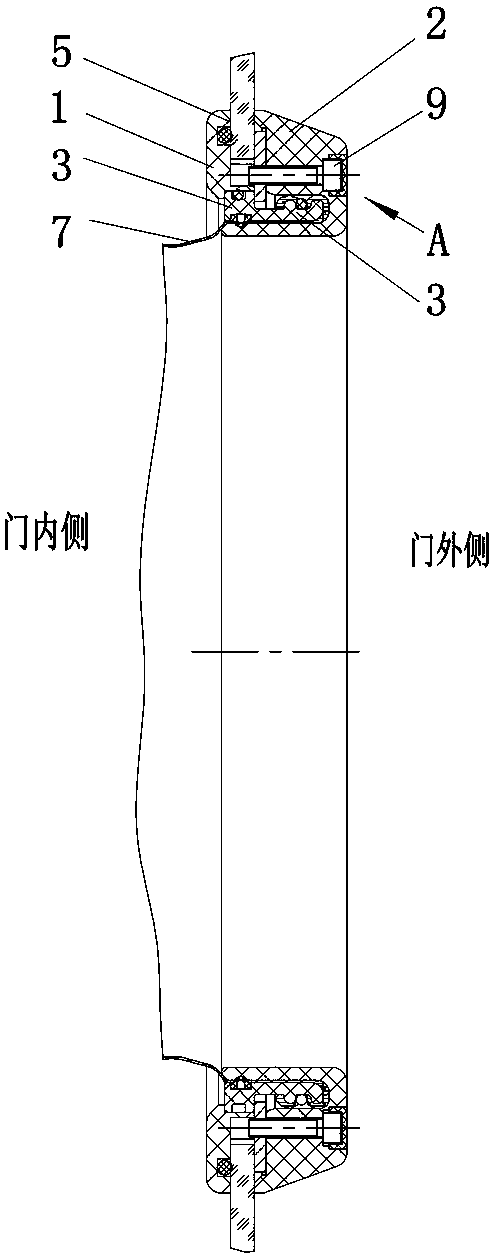

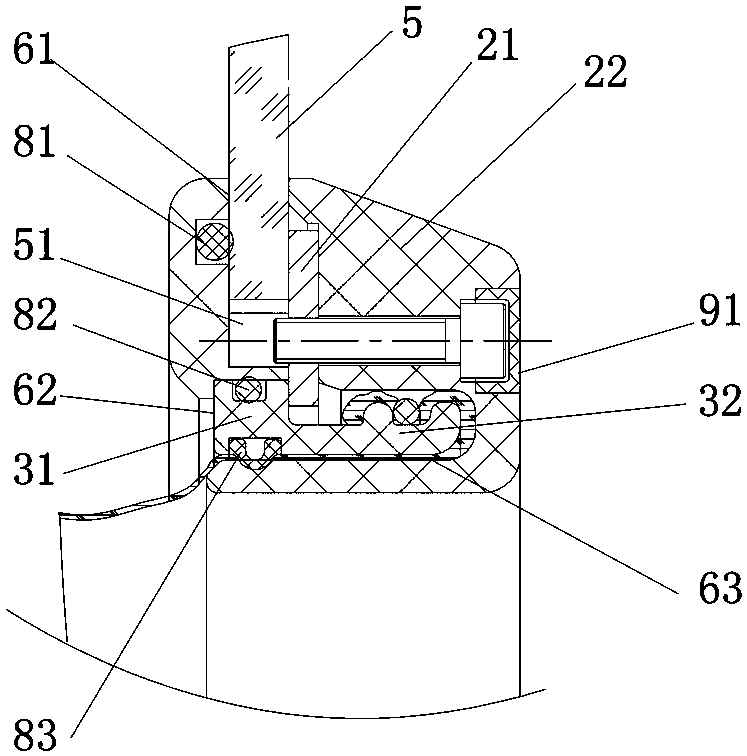

[0034] Such as Figure 1 to Figure 4 As shown, the flange assembly of the sterile glove of the present embodiment includes a first jacket 1, a second jacket 2 and a glove flange 3, and the glove flange 3 includes a fixing part 31 and a handle for installing a sterile glove 7. The glove installation part 32, the first jacket 1 and the second jacket 2 are connected by fasteners 4 to form a first annular groove 61 where the glass door 5 is clamped and a second annular groove 62 where the fixing part 31 is embedded. The jacket 2 is provided with a third annular groove 63 for accommodating the glove mounting portion 32 .

[0035] In a specific application example, the glove installation part 32 may face the first jacket 1 or the second jacket 2. In this embodiment, the glove installation part 32 faces the second jacket 2 and is located in the third annular groove 63 Inside, and the fixing part 31 is supported on the side wall of the third annular groove 63 to ensure that the glove...

Embodiment 2

[0046] Such as Figure 5 and 6 As shown, the flange assembly of the sterile glove of this embodiment is basically the same as that of Embodiment 1, the only difference being:

[0047] In this embodiment, the first jacket 1 is arranged on the outside of the glass door 5 , and the second jacket 2 is arranged on the inside of the glass door 5 . In this way, the second jacket 2 with a larger thickness is arranged on the inside of the glass door 5, and the first jacket 1 with a smaller thickness is arranged on the outside of the glass door 5, which not only occupies a small space, but also is beautiful.

Embodiment 3

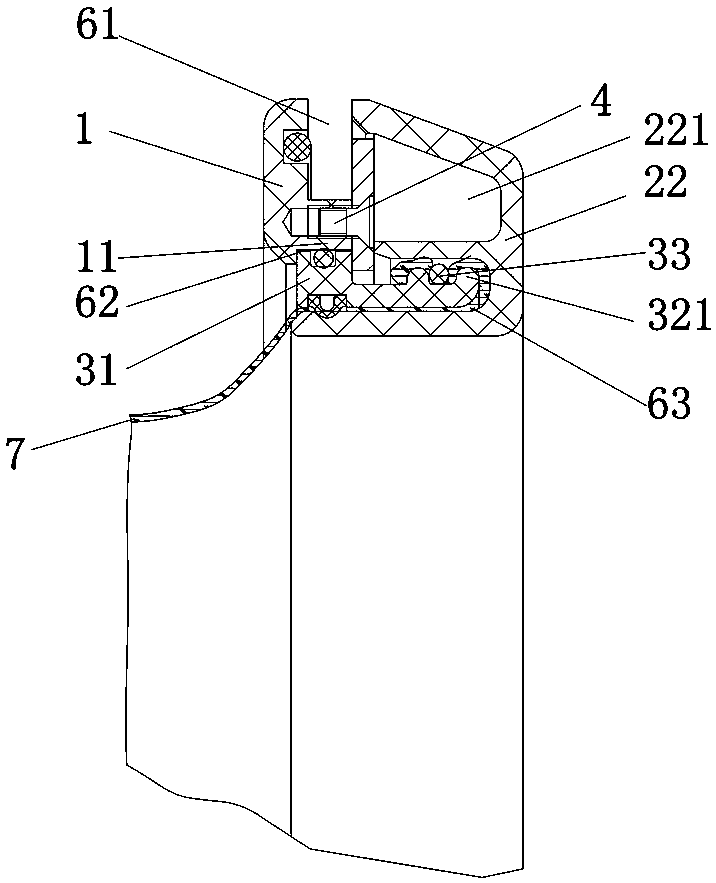

[0049] Such as Figures 7 to 9 As shown, the flange assembly of the sterile glove of this embodiment is basically the same as that of Embodiment 1, the only difference being:

[0050] In this embodiment, the glove installation part 32 is installed in the second annular groove 62 facing the first jacket 1 .

[0051] In this embodiment, the replacement of sterile gloves 7 is an internal replacement type. The replacement process is as follows: first put the sterilized new sterile gloves 7 into the isolator from the sterile inlet, and pass them to the old sterile gloves 7 to be replaced in the isolator; then put the old sterile gloves 7 Pull out to the outermost groove of the glove installation part 32, put the new sterile glove 7 on the old sterile glove 7, and place it in the innermost groove of the glove installation part 32; The old sterile gloves 7 are torn off and taken out from the new sterile gloves 7, and the replacement is completed. This replacement method is suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com