Battery cover plate component, battery cell, battery module, power battery pack and electric vehicle

A battery cover and component technology, which is applied to battery pack components, battery cover/end cover, electrical components, etc., can solve the problems of failure to protect the battery, failure to disconnect the pull-off structure in time, and battery scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

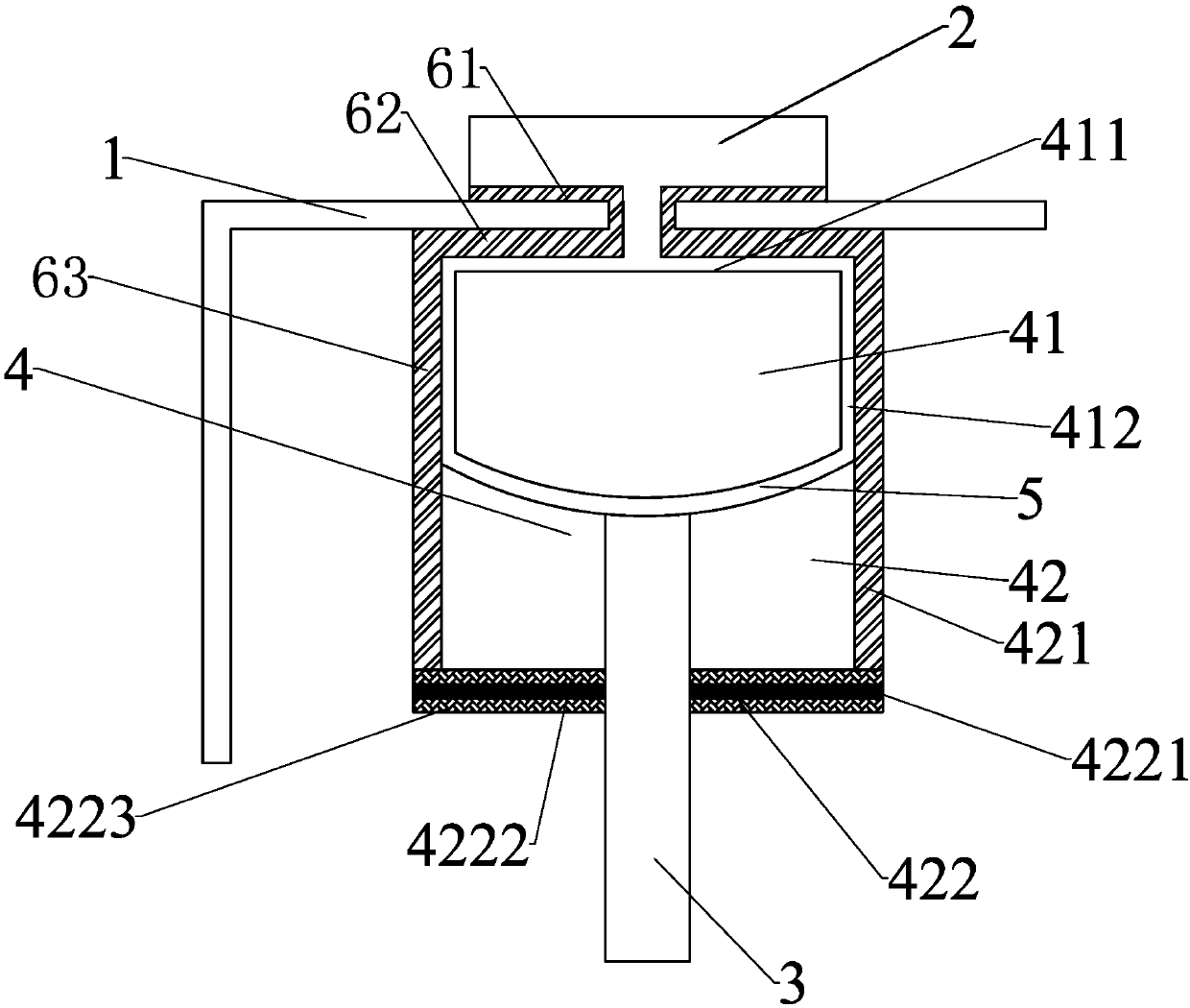

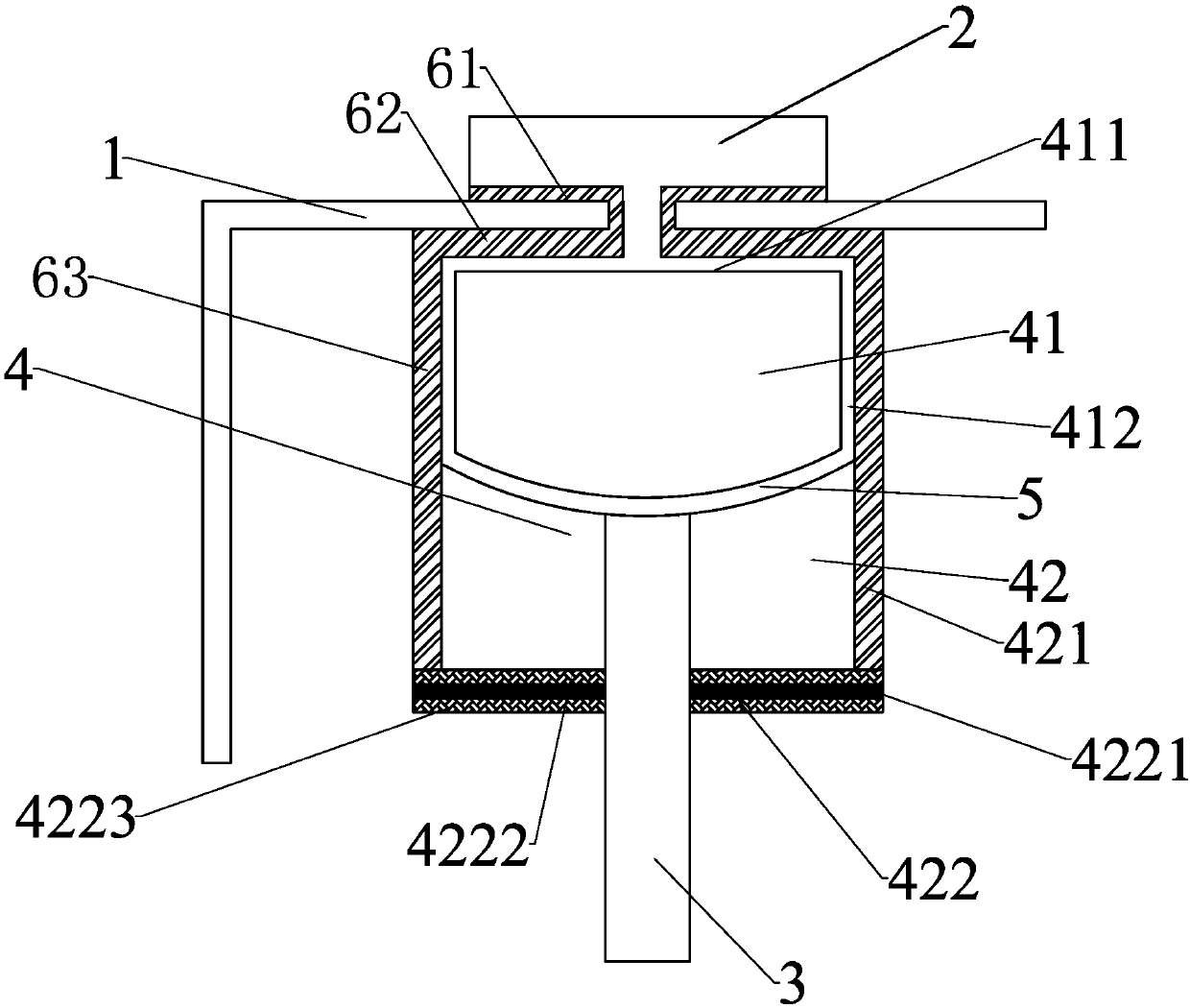

[0045] Wherein, the sealed cavity 4 includes a closed first sealed cavity 41 and a second sealed cavity 42 outside the first sealed cavity 41 . The first sealed cavity wall of the first sealed cavity 41 may be an independent closed system, or a part of the sealed cavity wall of the sealed cavity 4 may be used. Specifically, in one embodiment, the first sealed cavity 41 is located in the sealed cavity 4, and the second sealed cavity 42 surrounds the first sealed cavity 41, that is, the first sealed cavity 41 has an independent closed system, and the second sealed cavity 42 wraps the first sealed cavity. A sealed cavity 41, preferably, the first sealed cavity 41 is located in the upper part of the sealed cavity 4 to facilitate the connection of the electrode outer terminal 2 with the first sealed cavity 41, and to facilitate the gas in the second sealed cavity 42 to disconnect the electrode internal terminal 3 and Electrical connection of electrode external terminal 2. In the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com