Electric connector

A technology for electrical connectors and docking parts, which is applied in the directions of connections, circuits, and parts of connecting devices, etc., can solve problems such as unfavorable high-frequency connector transmission rate, poor impedance matching of high-frequency connectors, and large differential signal transmission loss. , to improve the impedance low point, improve the matching, and improve the high-frequency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

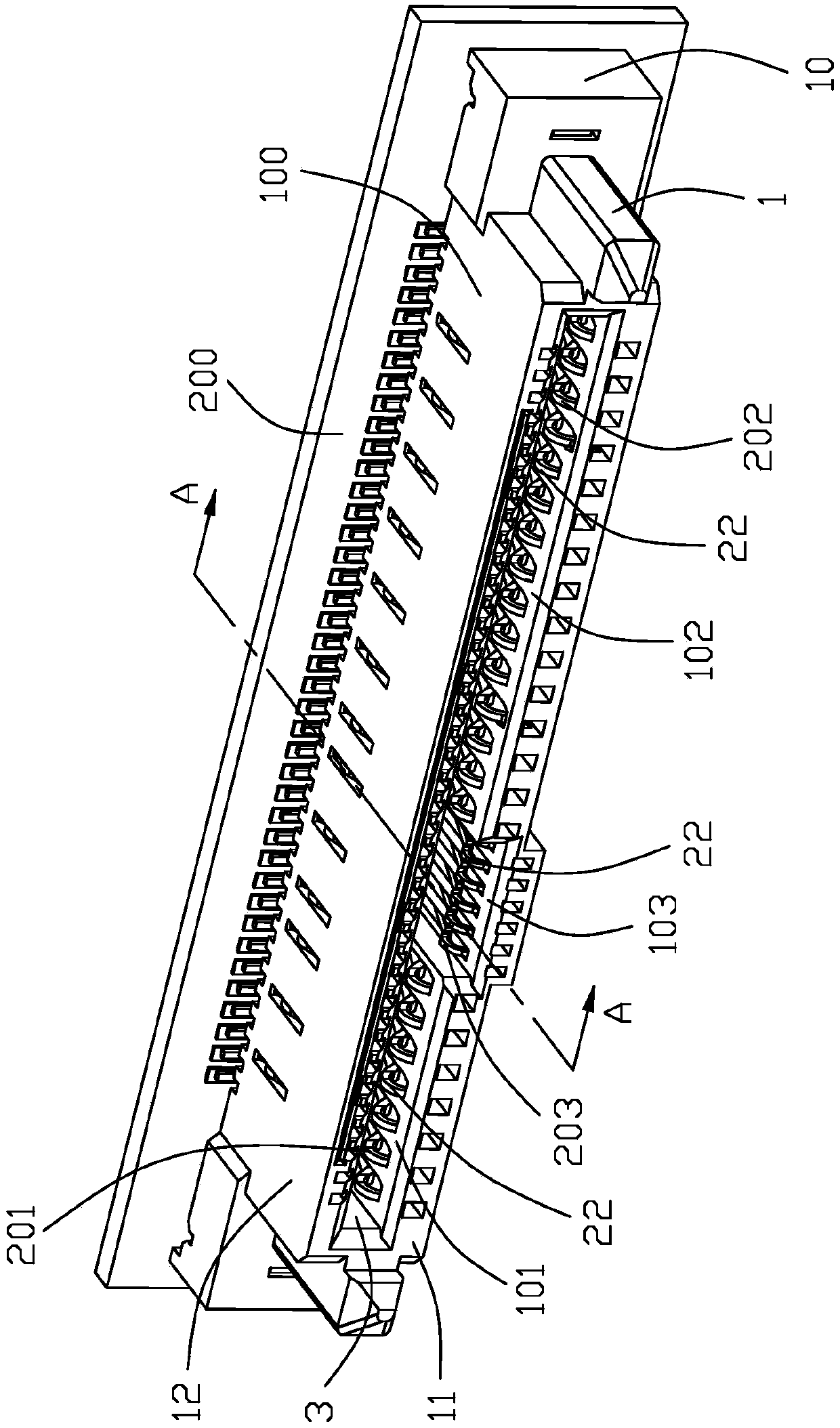

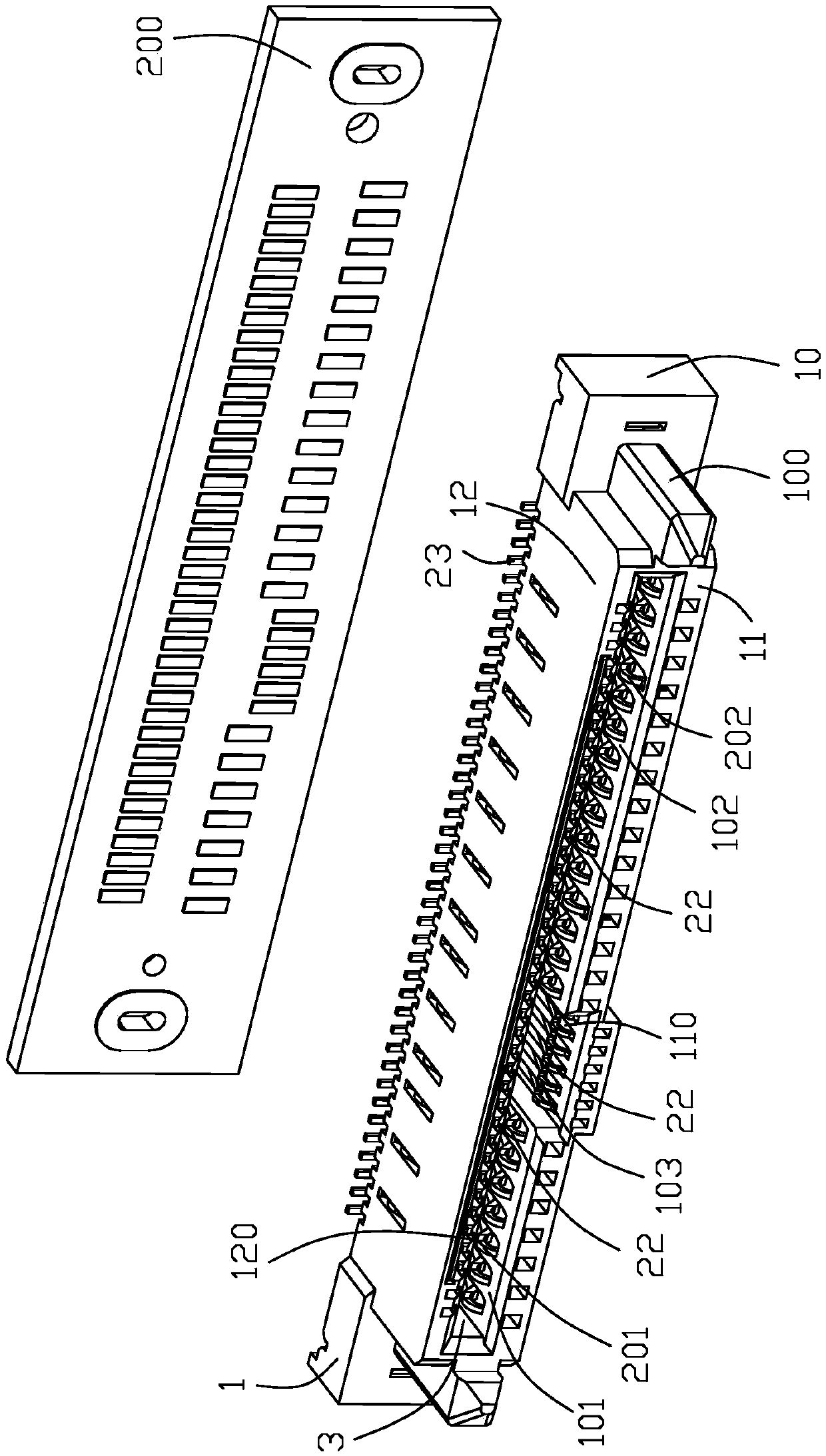

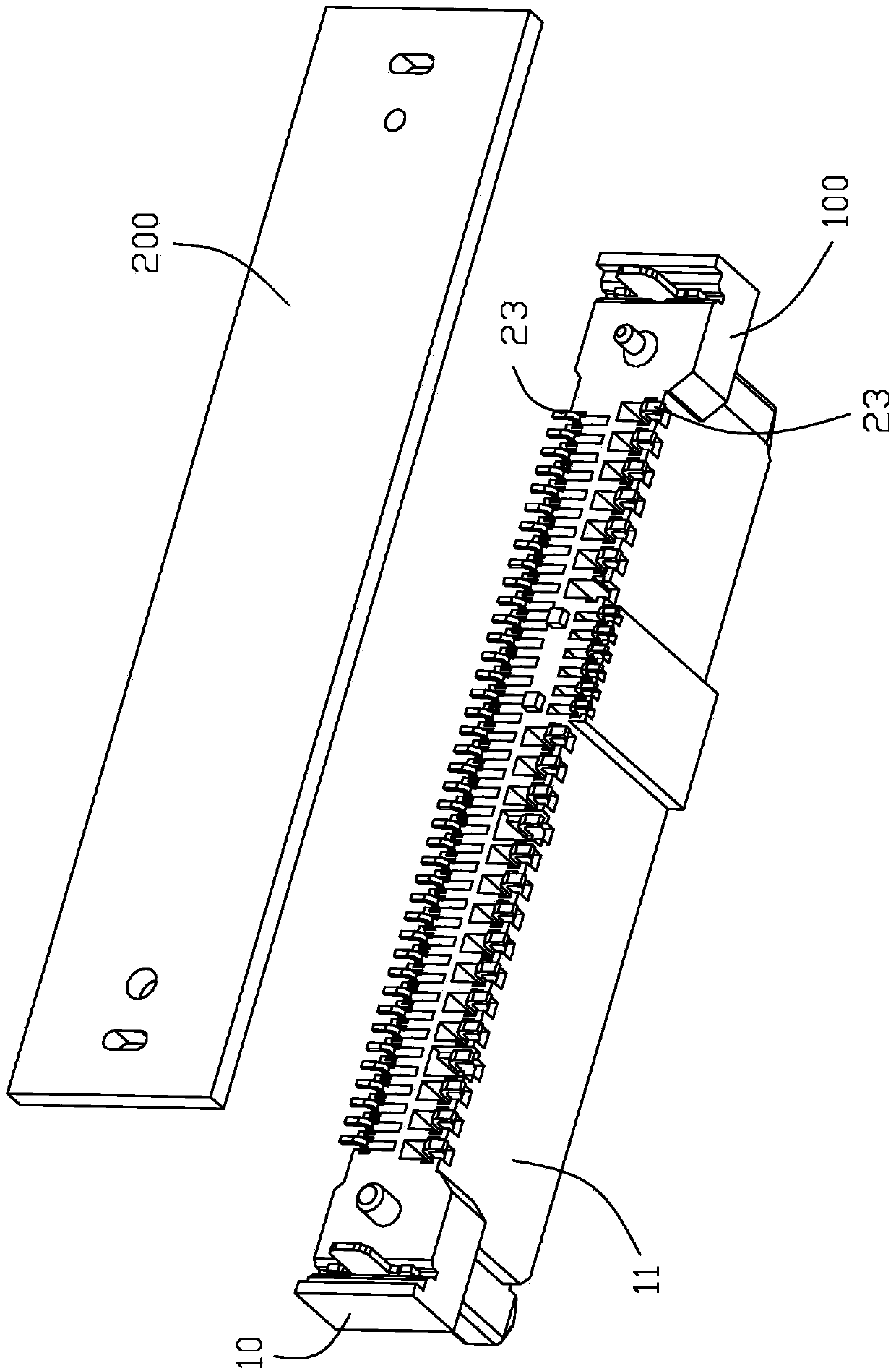

[0047] Below, will combine Figure 1 to Figure 9 The specific implementation manner of the conductive terminal of the present invention is introduced.

[0048] Such as Figure 1 to Figure 7 As shown, the present invention provides an electrical connector 100 for mounting on a circuit board 200 to transmit high-frequency signals, comprising a lengthwise insulating body 1 and a plurality of conductive terminals 2 held in the insulating body 1, the The insulating body 1 is provided with a continuous receiving groove 3 along its longitudinal direction, and the insulating body 1 includes a base 10, a first side wall 11 and a second side wall 12, and the first and second side walls 11, 12 Extended from the base 10 and located on opposite sides of the receiving groove 3 , the conductive terminal 2 is held on the first and second side walls 11 , 12 and includes a fixing portion fixed on the base 10 21. The arc-shaped bent contact portion 22 extending into the receiving groove 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com