A kind of preparation method of polyimide resin and film thereof

A polyimide resin and film technology, which is applied in the preparation method of polyimide resin and the field of film, can solve the problems of difficulty in stabilizing resin viscosity, reducing the performance and quality of polyimide resin, and difficult polycondensation, etc., to achieve a solution Easy to crimp, lower dielectric constant, and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] Based on the problem that the performance and viscosity of polyimide resins prepared in China cannot be preserved for a long time under normal temperature and pressure, the invention provides a preparation method of polyimide resins, comprising the following steps:

[0013] S1. After dissolving the first batch of polyvalent diamines in a solvent under an inert gas atmosphere, add 105-110% of the first batch of polyvalent diamines in a low-temperature environment at or below 30°C to polymerize and form Resin solution, control the resin solution viscosity at 50000-70000 cps;

[0014] S2. Monitor the viscosity of the resin solution and gradually increase the temperature within 30-80°C, and gradually add the second batch of polydiamine in batches, first more and then less, until the viscosity of the resin solution is 180000-200000cps;

[0015] S3, adding a fluorine-containing end-capping agent and mixing evenly, and obtaining a polyimide resin solution after high-vacuum def...

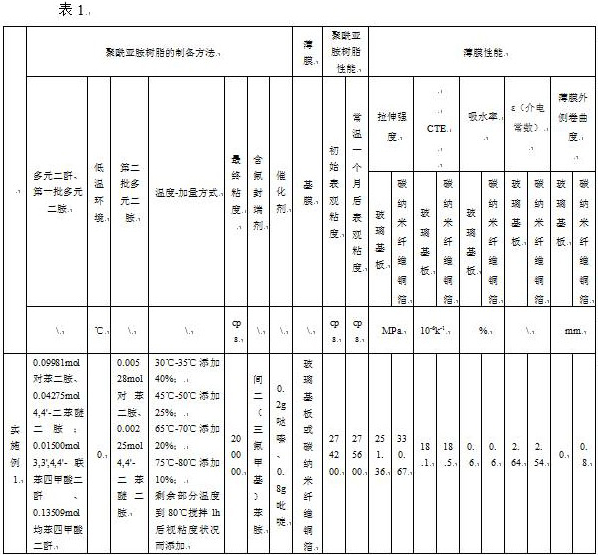

Embodiment 1

[0032] Weigh 245.98g of N,N-dimethylformamide (analytical grade) and high-purity nitrogen atmosphere in a flask, weigh 0.09981mol of p-phenylenediamine and 0.04275mol of 4,4'-diphenyl ether diamine in the flask Dissolve completely; weigh 0.01500mol of 3,3',4,4'-biphenyltetracarboxylic dianhydride and 0.13509mol of pyromellitic dianhydride, mix them into the flask, and control the reaction temperature at about 0°C.

[0033] After 120 minutes of reaction, the temperature of the water bath began to rise to 80°C. Weighed 0.00528mol of p-phenylenediamine and 0.00225mol of 4,4'-diphenyl ether diamine and dissolved them in 20g of N,N-dimethylformamide under a nitrogen atmosphere. The configured mixed solution adopts the principle of adding more first and then less multiple times by the differential method, adding 40% at 30°C-35°C, adding 25% at 45°C-50°C, adding 20% at 65°C-70°C, adding 20% at 75°C-80°C 10%, and the remaining part is added depending on the viscosity after stirrin...

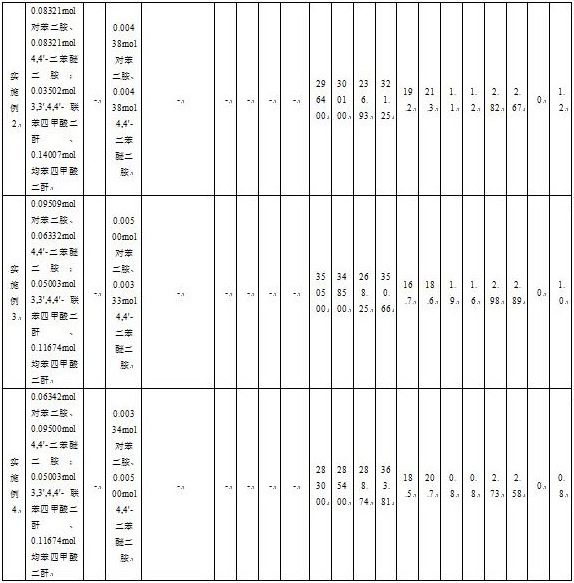

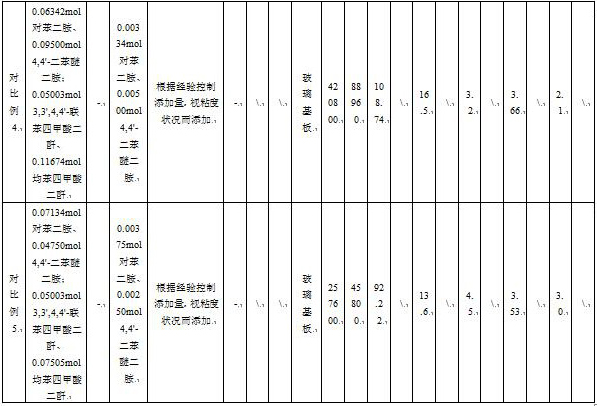

Embodiment 2

[0035] Weigh 307.85g of N,N-dimethylformamide (analytical grade) and high-purity nitrogen atmosphere in a flask, weigh 0.08321mol of p-phenylenediamine and 0.08321mol of 4,4'-diphenyl ether diamine in the flask Dissolve completely; weigh 0.03502mol of 3,3',4,4'-biphenyltetracarboxylic dianhydride and 0.14007mol of pyromellitic dianhydride, mix them into the flask, and control the reaction temperature at about 0°C. After 120 minutes of reaction, the temperature of the water bath was raised to 80°C, and 0.00438mol of p-phenylenediamine and 0.00438mol of 4,4'-diphenyl ether diamine were weighed and dissolved in 4g of N,N-dimethylformamide under a nitrogen atmosphere. To configure the mixed solution, the difference method is used to add more first and then less. Add 40% at 30°C-35°C, 25% at 45°C-50°C, 20% at 65°C-70°C, and 10% at 75°C-80°C. %, the remaining part is added depending on the viscosity after stirring at 80°C for 1 hour. The stirring rate is 15 rad / min, and the apparent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com