A low-capacitance vertical-cavity surface-emitting laser and its manufacturing method

A vertical cavity surface emission and manufacturing method technology, applied in the field of vertical cavity surface emitting lasers and production, can solve the problems of poor MIS capacitance effect reduction effect, serious electrode capacitance effect, and deterioration of chip solderability, etc., to reduce MIS Effect of capacitive effect, reduction of dielectric constant, and improvement of solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

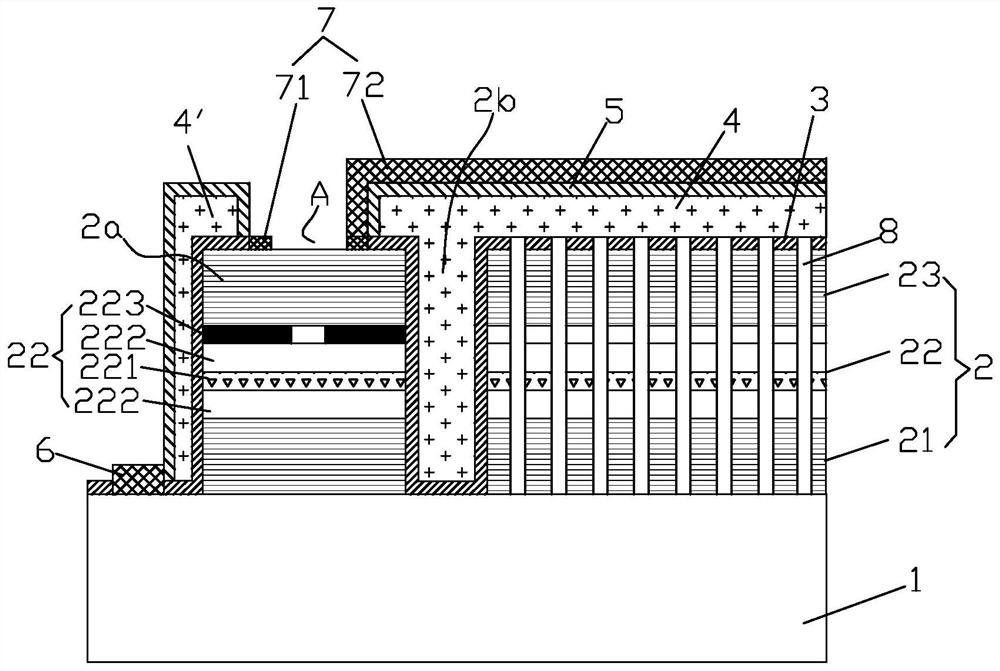

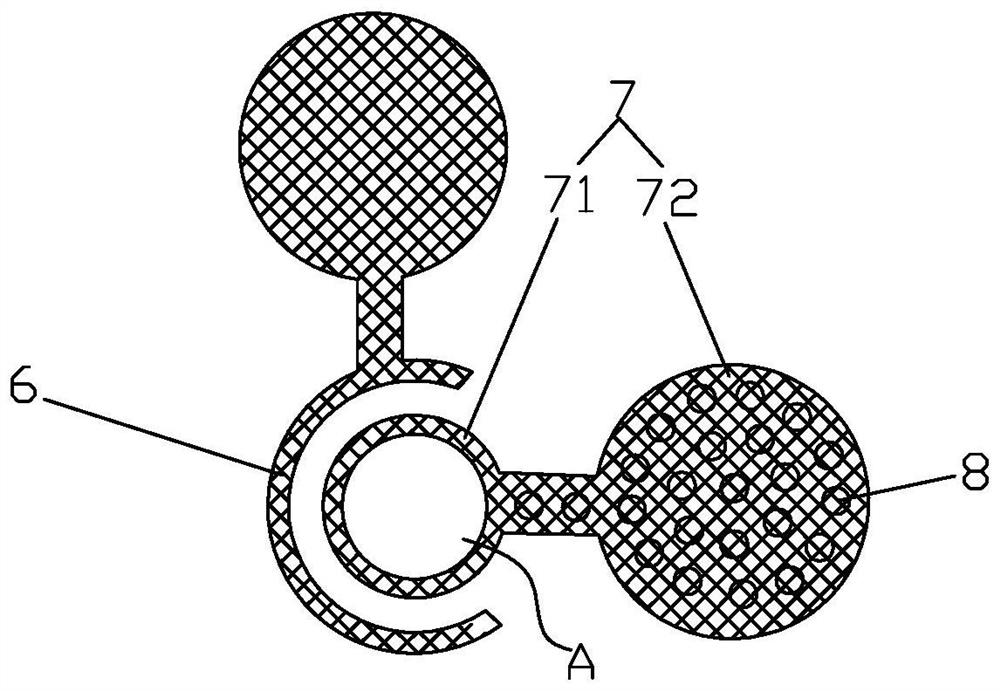

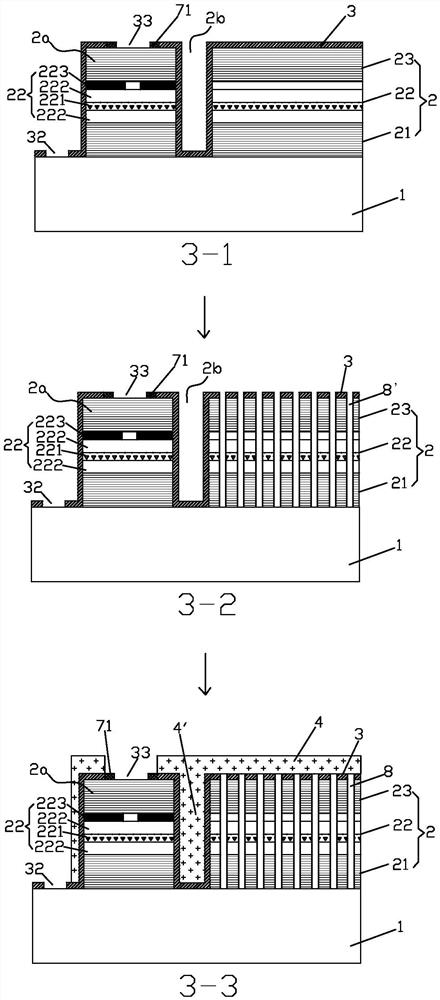

[0038]With the above structure, the first DBR 21 has a thickness of 5.14 μm and an equivalent dielectric constant of 11.59; the resonant cavity 22 has a thickness of 0.0.246 μm and an equivalent dielectric constant of 11.35; the second DBR 23 has a thickness of 3.19 μm and an equivalent The dielectric constant is 11.59; the thickness of the organic polymer layer 4 is 1 μm, and the dielectric constant is 2.25; the total thickness of the first dielectric layer 3 and the second dielectric layer 5 is 0.2 μm, and the dielectric constant is 3.8. The total area of the air column 8 accounts for 50% of the coverage area of the lead-out portion 72 , and the air column 8 penetrates the epitaxial layer 2 . It can be seen through calculation that the equivalent dielectric constant of the above structure is reduced by 44%, and thus the electrode capacitance can be reduced by more than 44%.

[0039] By setting the percentage of the total area of different air columns to the coverage ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com