Ridge-planting straw crushing and returning machine for ridge-furrow operation

A technology of straw crushing and ridge furrowing, which is applied in the field of ridge farming straw crushing and returning machines, which can solve the problems of incapable of straw crushing operations and fast plowing and sowing agronomy, and achieves the effects of saving manpower and material resources, simple structure, and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

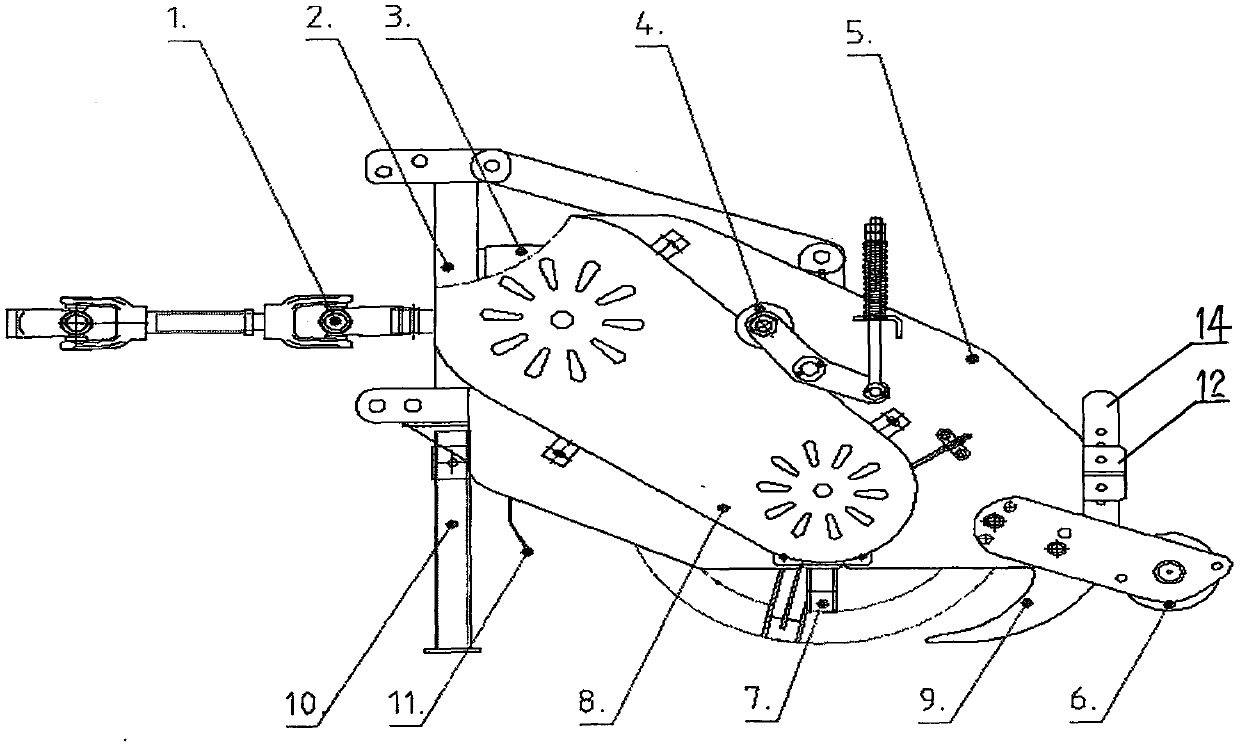

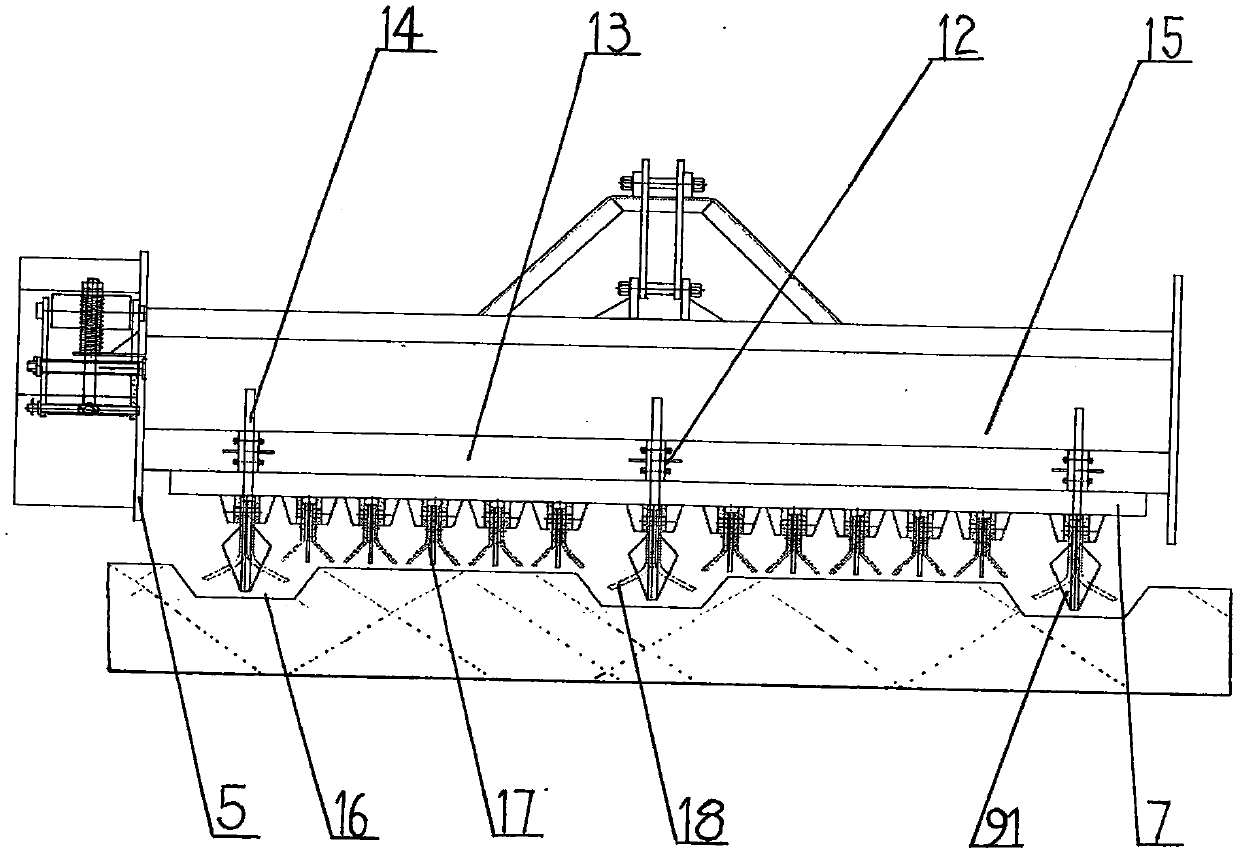

[0023] Embodiment 1: as Figure 1 to Figure 6 As shown, the present invention is provided with a stalk picking plow hook device 9 on the back beam of the ridge-growing straw crushing and field returning machine.

[0024] The straw picking plow hook device is provided with several plow hook fixing seats 12 on the rear beam 13 of the straw crushing and field returning machine according to the same size of the center distance of the furrows 16 in the field. The two ends of the back beam are integrated with the two side frames of the corresponding part, the front end of the back beam is a casing plate, and the front side of the lower end of the back beam is a straw crushing knife roller.

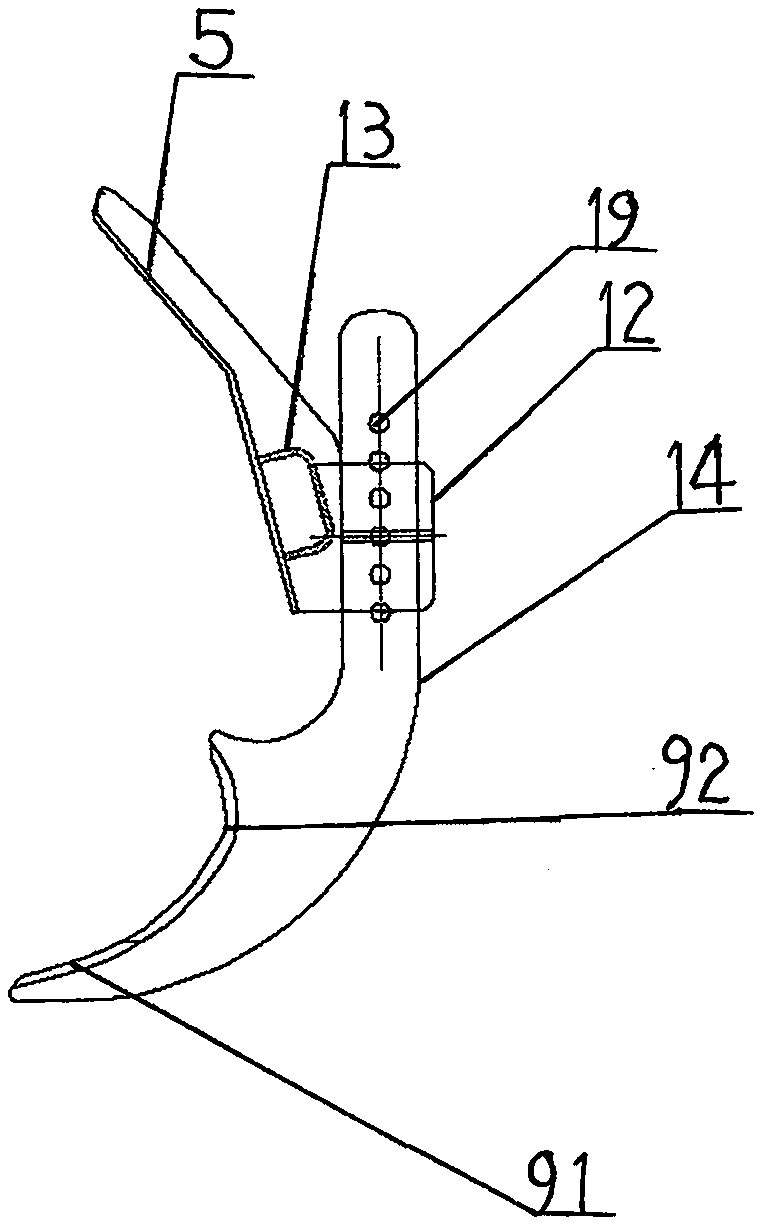

[0025] The plow hook fixed seat is horizontally provided with a penetrating adjustment seat screw hole 33, and the upper end of the plow hook rod 14 is fixed in the plow hook fixed seat from bottom to top, and the lower end of the plow hook rod is a fixed baffle seat 94. The corresponding adjus...

Embodiment 2

[0033] Embodiment 2: as Figure 1 to Figure 7 As shown, the present invention is equipped with a straw picking plow hook device on the front end frame of the rear limit ground wheel of the ridge farming straw crushing and returning machine.

[0034] The straw picking plow hook device is provided with a support beam 30 with two ends fixed to the corresponding frame on the front end frame of the rear limit ground wheel 6 of the straw crushing and field returning machine. And the cross-section of the plow hook bar is rectangular. Several sliders 31 are slidingly fitted on the support beam, and the upper end of each slider is provided with a slider fixing screw hole 32, and the fixing screw holes communicate with the upper end surface of the slider, and the lower part of the slider fixing bolt is screwed on the slider fixing screw. In the hole, the slide block can be fixed on the supporting beam corresponding to the upper end of the ditch through the slide block fixing bolt. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com