Box body assembling system and method of polyurethane insulation box for liquefied natural gas (LNG) ships

An assembly system and LNG ship technology, which is applied in the field of box assembly system of polyurethane insulated boxes for LNG ships, can solve problems such as substandard connection strength and assembly accuracy, low production efficiency, and uneven stress on splints, etc., to achieve consistent product quality Good performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]L03, L03+ and other types of reinforced polyurethane insulation boxes are composed of multiple polyurethane boards, plywood and wooden splints and other components that are glued and assembled; this embodiment overcomes the shortcomings of the prior art in the assembly quality control method, and designs a The control system and method for the box assembly accuracy of LNG-enhanced polyurethane standard insulation boxes in the form of L03, L03+, etc., which are suitable for multi-type L03, L03+, etc., take advantage of the high efficiency of automation equipment, and the key points for glued plywood, polyurethane board and wooden plywood, etc. The final assembly dimensional accuracy of the part and the reliability of the glued joint are overall corrected.

[0037] The part of the insulating box assembled in the previous process is sent into the assembly system by the material conveying mechanism, and then the corrected insulating box is sent out by the material conveying m...

Embodiment 2

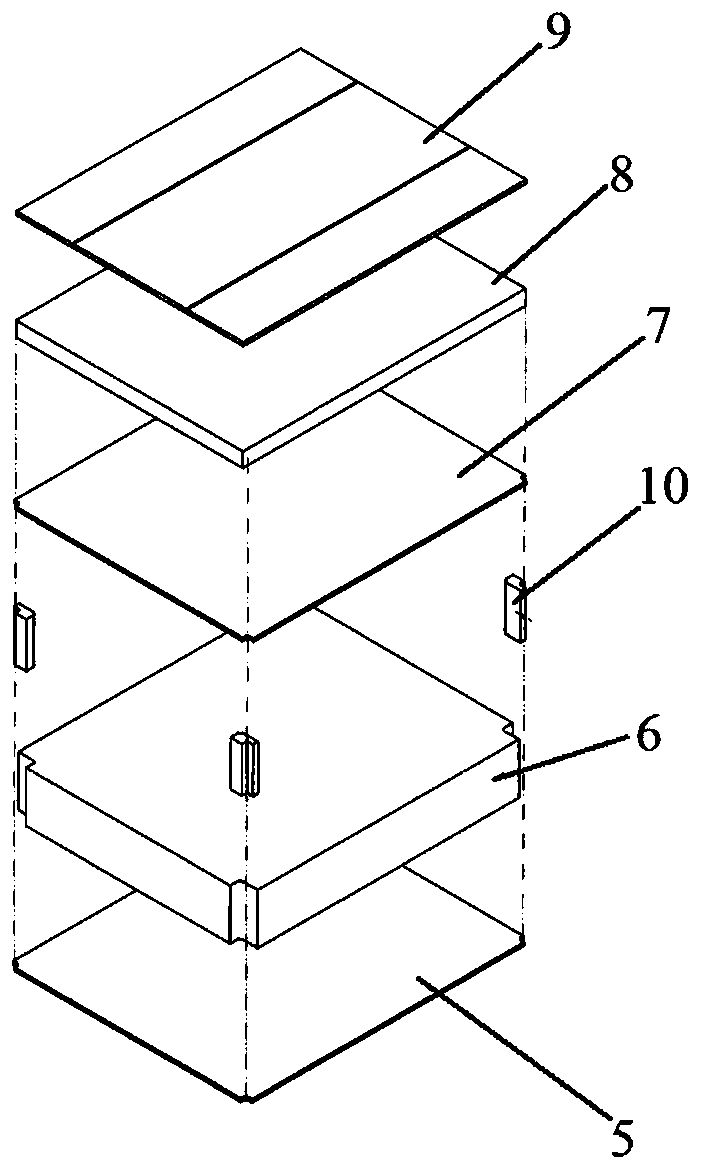

[0139] Such as figure 1 As shown, the L03 type insulation box includes the bottom plywood 5, the bottom polyurethane board 6, the middle plywood 7, the top polyurethane board 8, the top plywood 9 and four layers respectively arranged on the bottom polyurethane board 6. Wood splint 10 at four corners.

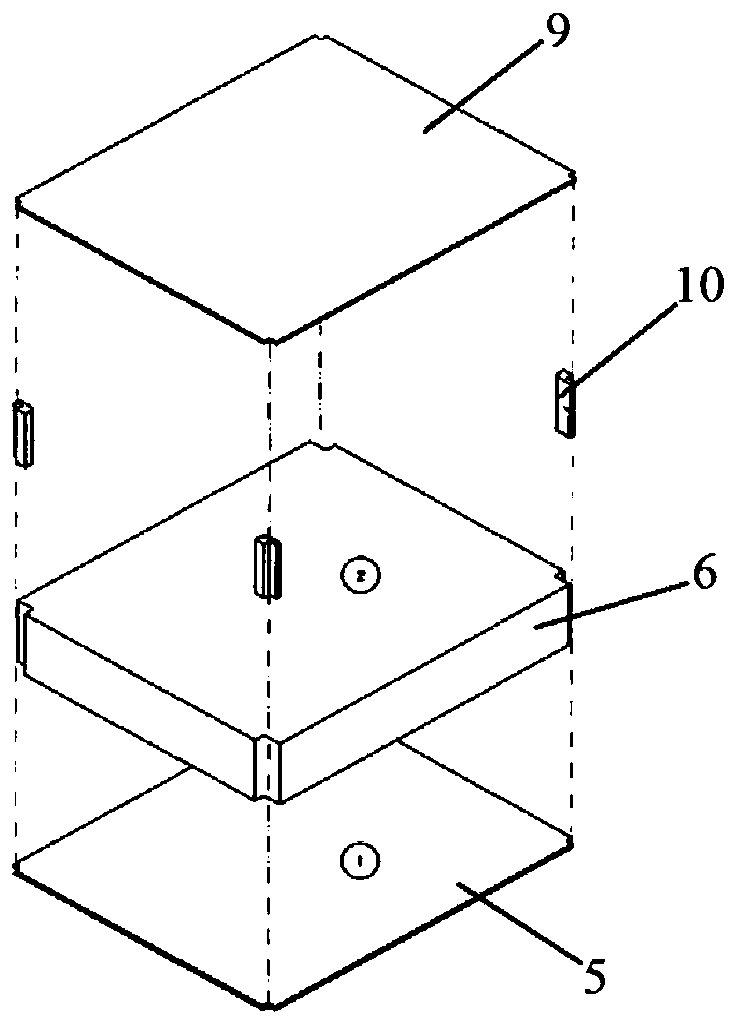

[0140] Such as figure 2 As shown, the L03+ type insulating box includes a bottom plywood 5, a bottom polyurethane board 6, a top plywood 9 and four wooden splints 10 respectively arranged at the four corners of the bottom polyurethane board 6, which are laminated together from bottom to top.

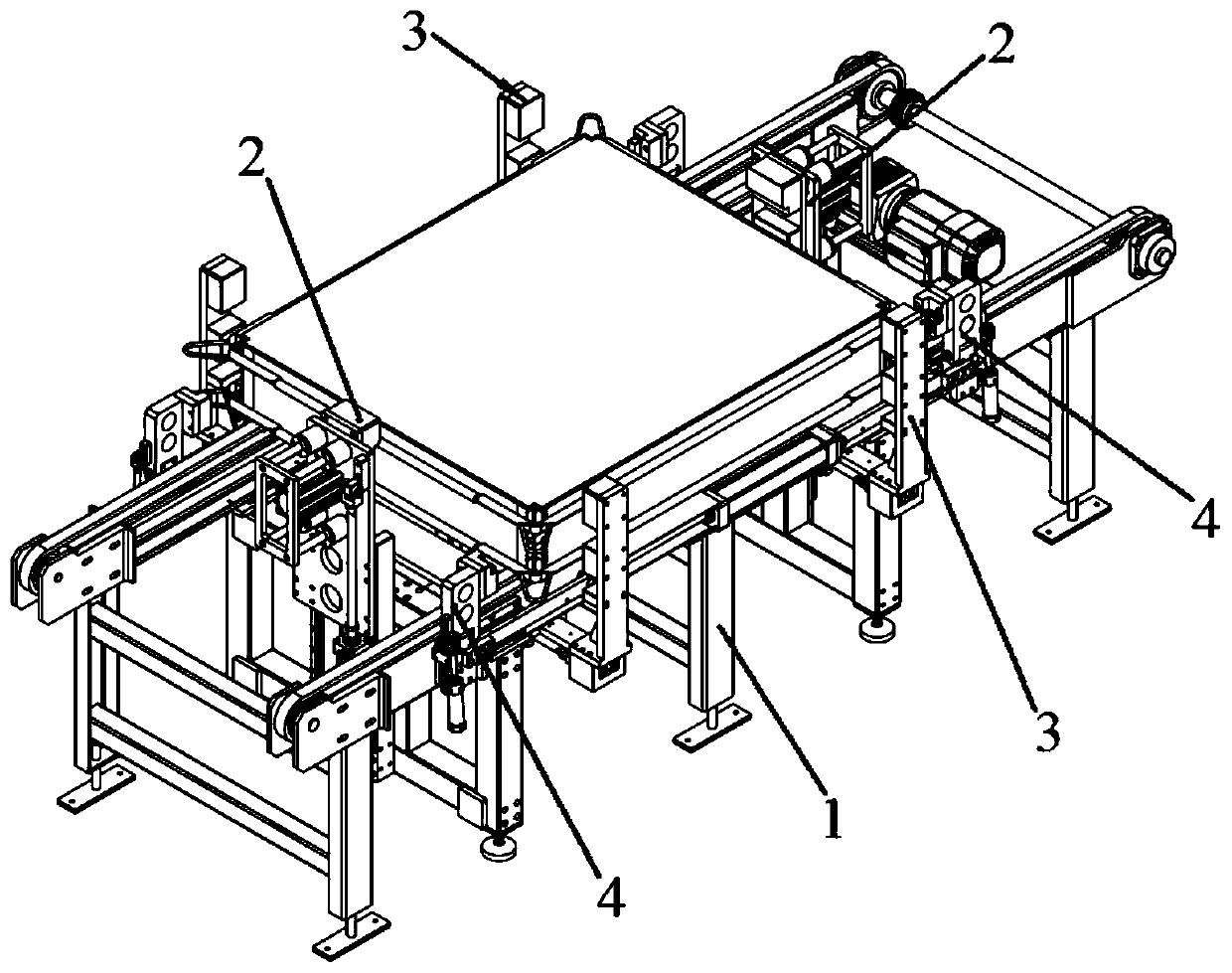

[0141] Such as image 3 The box assembly system of the polyurethane insulation box for LNG ships shown includes a base 1 and an X-direction positioning correction mechanism 2 , a Y-direction positioning correction mechanism 3 , and a wooden splint correction mechanism 4 respectively arranged on the base 1 . A pair of X-direction positioning correction mechanisms are arranged along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com