Field disassembling and assembling process of upper reactor internal control rod guide cylinders

A technology of guide cylinders and internal components, which is applied in the field of on-site disassembly and assembly of control rod guide cylinders of upper reactor internal components, can solve the problems of unreachable personnel and limited operating space of the upper support plate, so as to avoid equipment damage, stabilize and Precise dismantling and assembly, tools and simple process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

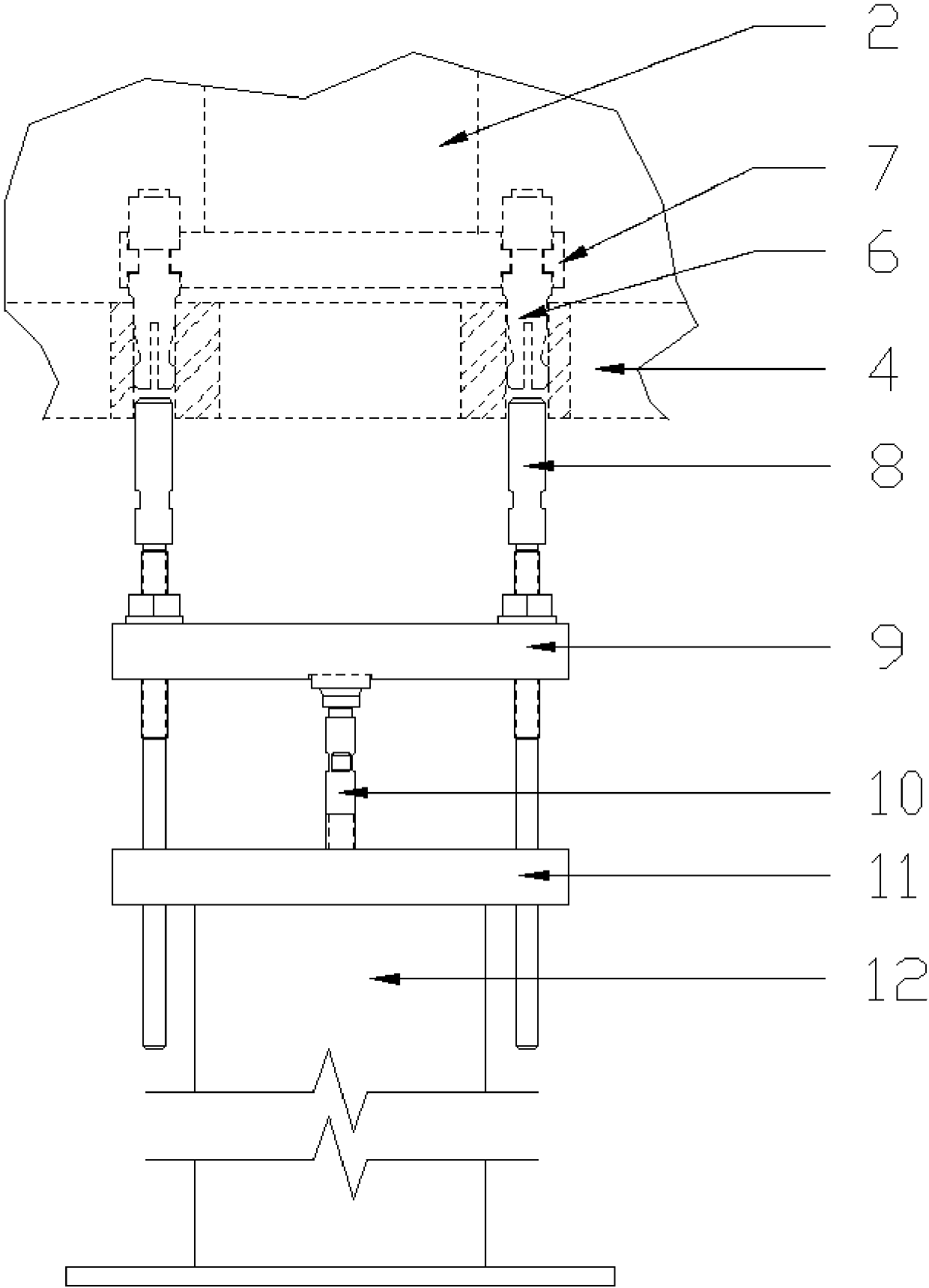

[0085] Such as figure 2 As shown, a support pin ejection tool is mainly composed of a support base, a coarse thread screw, a top plate, two ejector rods and other components. The upper plate of the support base is tapped with a threaded through hole, which is engaged with the screw mandrel. The screw mandrel is processed with a flat or hexagonal head for screwing. The two ejector rods pass through the upper plate and the top plate of the support base and pass through Intermediate threads and nuts are fixed on the top plate. By turning the screw mandrel, the top plate and the two ejector rods are fed upwards, and an upward thrust can be applied to the support pin of the lower guide cylinder.

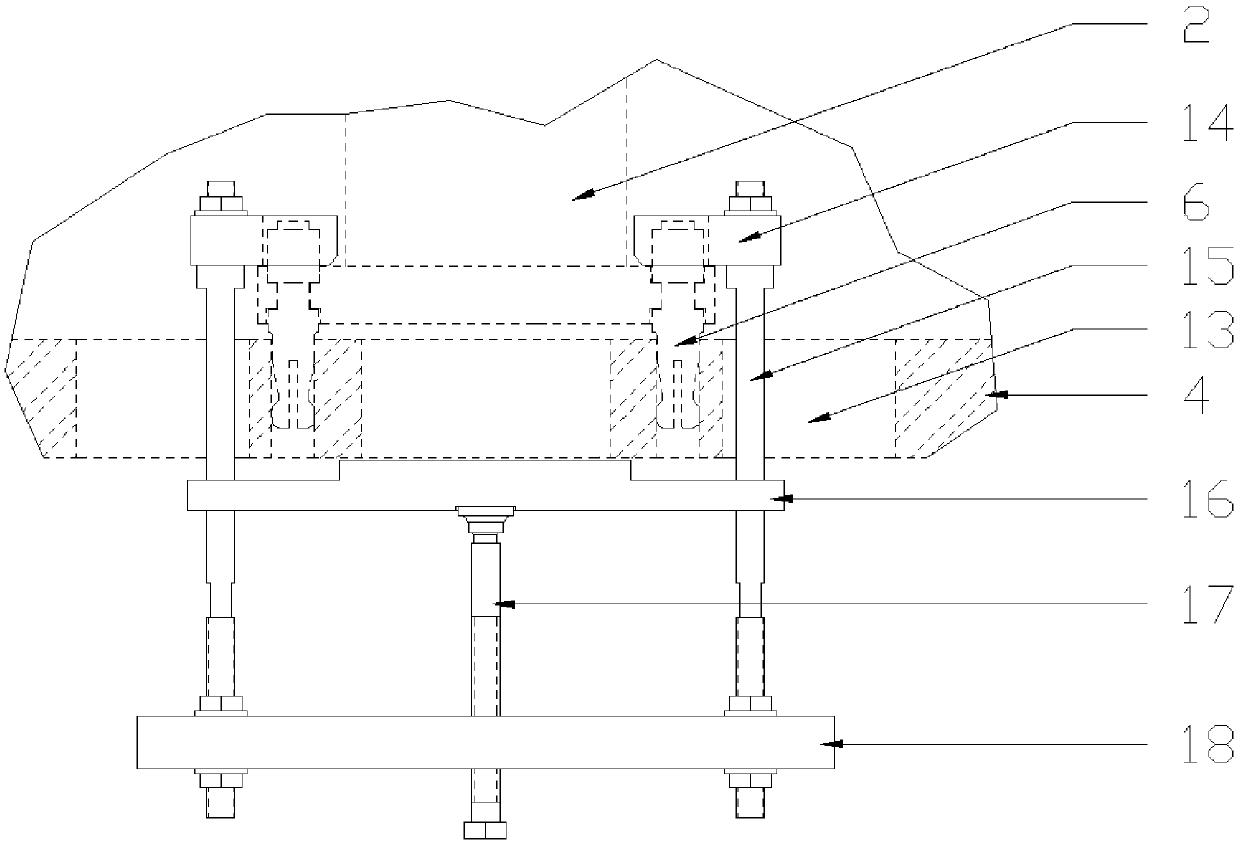

[0086] Such as image 3 , 4 As shown, a support pin press-in tool is mainly composed of two pull claws, two pull rods, a pull plate, a coarse tooth screw, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com