Integrated rear axle assembly with automatic gear shifting transmission for electric vehicle, and gear shifting method

An automatic shifting and transmission technology, applied in electric vehicles, control drive, power management, etc., can solve the problems of damage to the motor, electronically controlled battery system, large load of the motor and rear axle, and inability to take into account the climbing ability, etc., to achieve optimization. The effect of motor operating range, extending cruising range, reducing design matching and resource organization workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

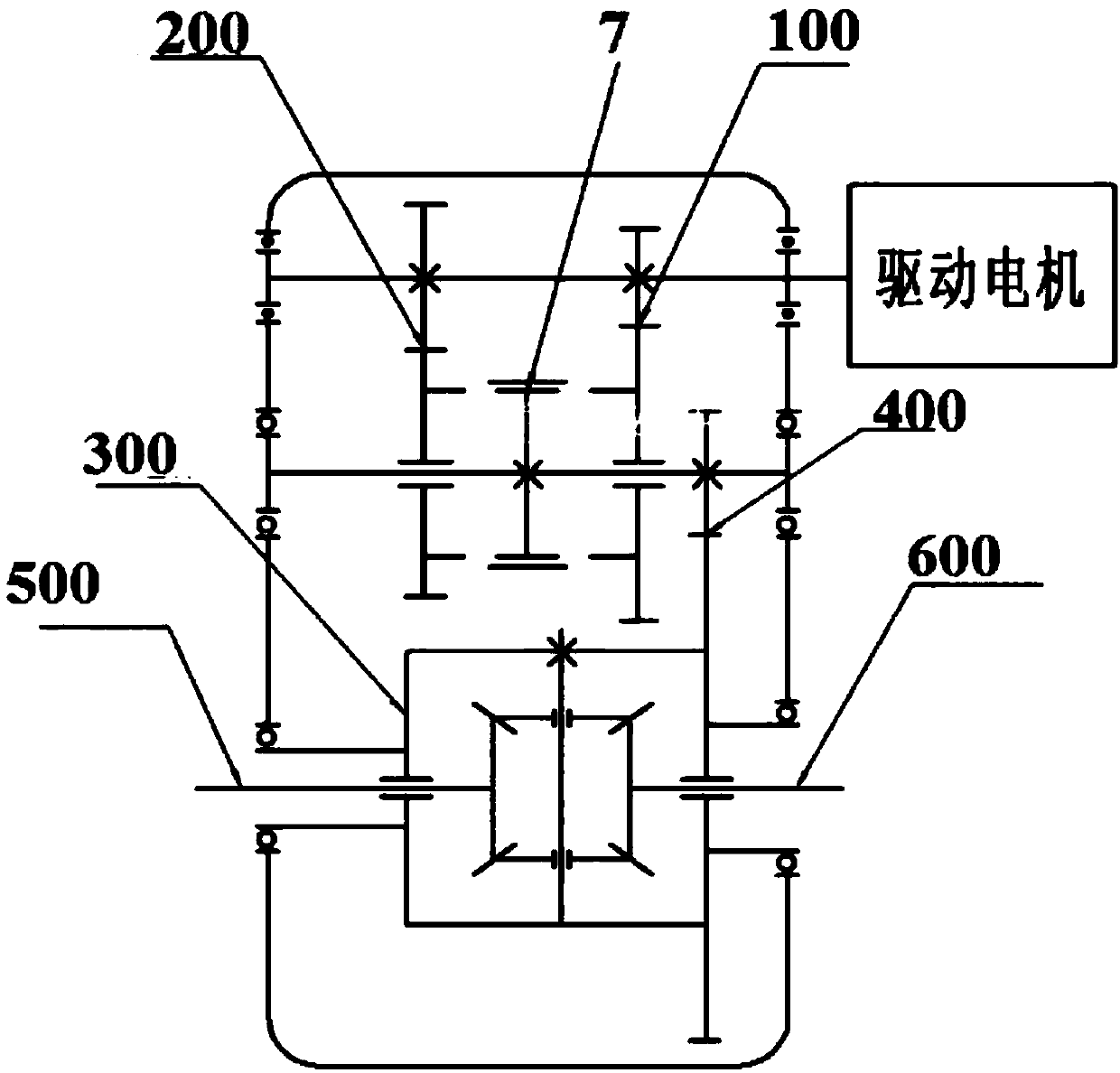

[0034] Embodiment 1: a rear axle assembly of an integrated automatic shift transmission for an electric vehicle, such as figure 1 As shown, 100-low speed gear set, 200-high speed gear set, 300-differential, 400-main reduction gear set, 500-left half shaft output, 600-right half shaft output.

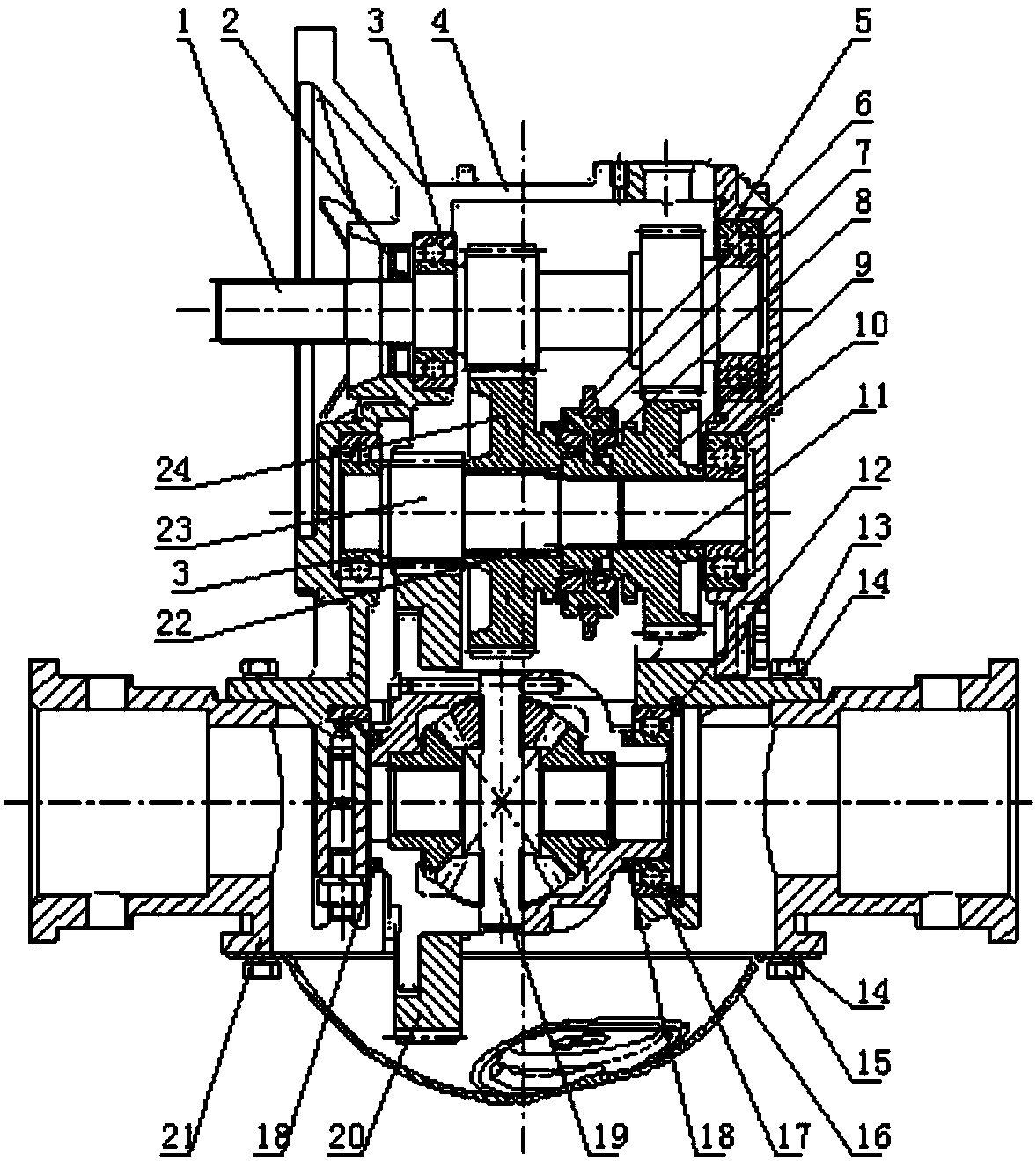

[0035] Such as figure 2 As shown, the transmission assembly includes: first shaft-1; oil seal-2; first bearing-3; box assembly-4; bearing-5; shift fork shaft rack-6; synchronizer-7; Synchronization ring-8; high-speed gear driven gear-9; second bearing-10; first needle bearing-11; stop ring-12; first bolt-13; spring washer-14; second bolt-15; rear axle Shell cover-16; third bearing-17; washer-18; differential gear assembly-19; first gear-20; casting middle section-21; second needle roller bearing-22; Driven gear-24; first pin-25; second pin-26;

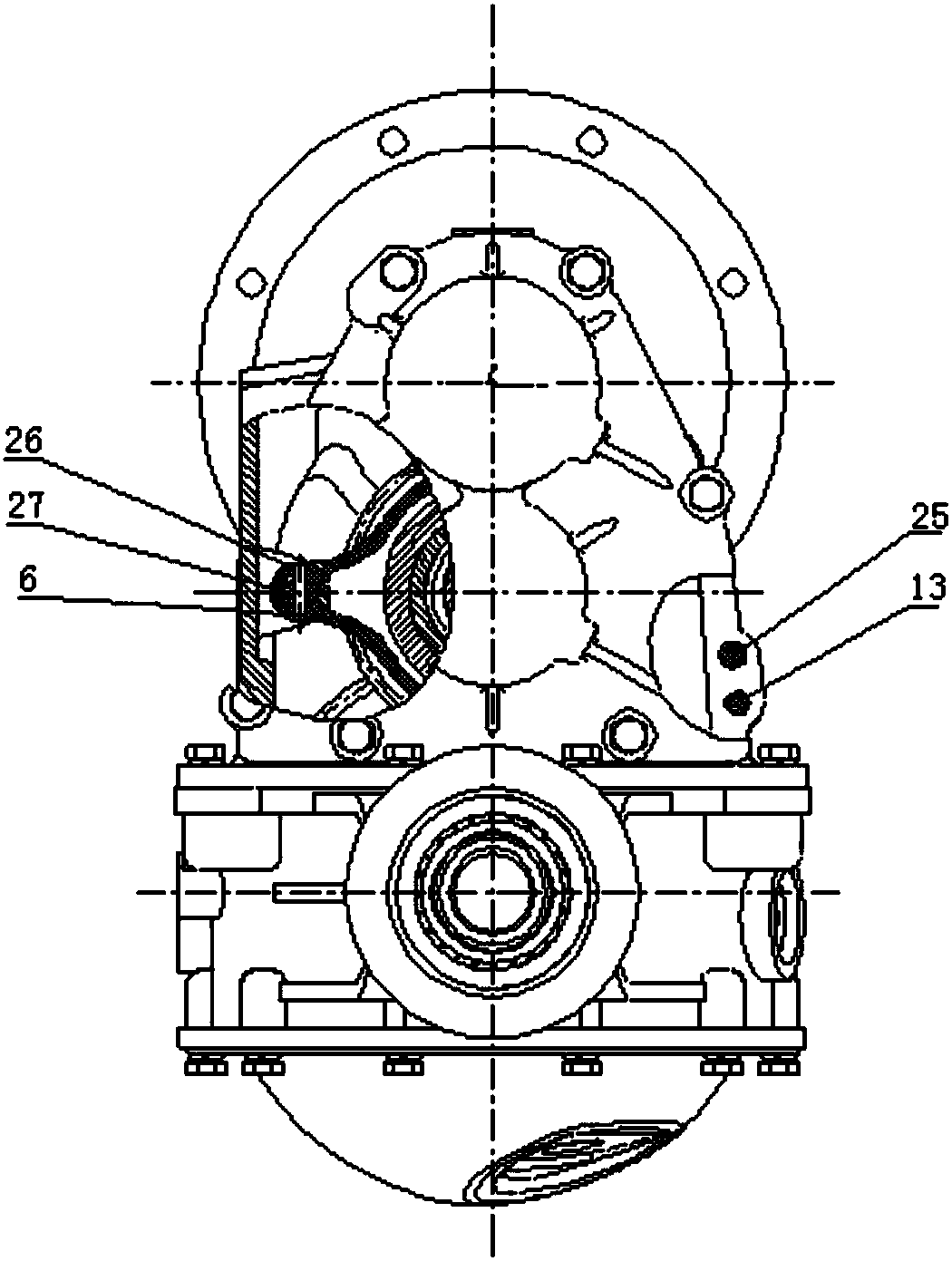

[0036] Such as image 3 As shown, it includes shift motor-28; first reduction gear-29; second reduction gear-30; third reduction gear-31; f...

Embodiment 2

[0041]A rear axle assembly of an integrated automatic shift transmission for an electric vehicle, which includes a drive motor 36, a first shaft 1, a second shaft 23, a high-speed gear set, a low-speed gear set, a synchronizer 7, and a differential assembly 19;

[0042] The drive motor 36 drives the first shaft 1 of the transmission; the first shaft and the second shaft are selectively meshed and connected through at least two sets of gear sets, and the two sets of gear sets include a high-speed gear set and a low-speed gear set. 7 Select the high-speed gear set or the low-speed gear set to achieve meshing;

[0043] The high-speed gear driving gear and the low-speed gear driving gear on the first shaft are respectively corresponding to the high-speed gear passive gear 9 and the low-speed gear driven gear 24 on the second shaft 23. By selecting the synchronizer, the high-speed gear on the first shaft is active The gear meshes with the high-speed passive gear on the second shaf...

Embodiment 3

[0046] A rear axle assembly of an integrated automatic shift transmission for an electric vehicle, which includes a drive motor 36, a first shaft 1, a second shaft 23, a high-speed gear set, a low-speed gear set, a synchronizer 7, and a differential assembly 19;

[0047] The drive motor 36 drives the first shaft 1 of the transmission; the first shaft and the second shaft are selectively meshed and connected through at least two sets of gear sets, and the two sets of gear sets include a high-speed gear set and a low-speed gear set. 7 Select the high-speed gear set or the low-speed gear set to achieve meshing;

[0048] The high-speed gear driving gear and the low-speed gear driving gear on the first shaft are respectively corresponding to the high-speed gear passive gear 9 and the low-speed gear driven gear 24 on the second shaft 23. By selecting the synchronizer, the high-speed gear on the first shaft is active The gear meshes with the high-speed passive gear on the second sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com