Electric vehicle frame and manufacturing method thereof

An electric vehicle and frame technology, applied in the field of electric vehicles, can solve the problems of easy discoloration and aging of plastic parts, low overall strength of electric vehicles, short cruising range, etc., and achieve the effects of improving cruising ability, high recycling value and comfortable riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

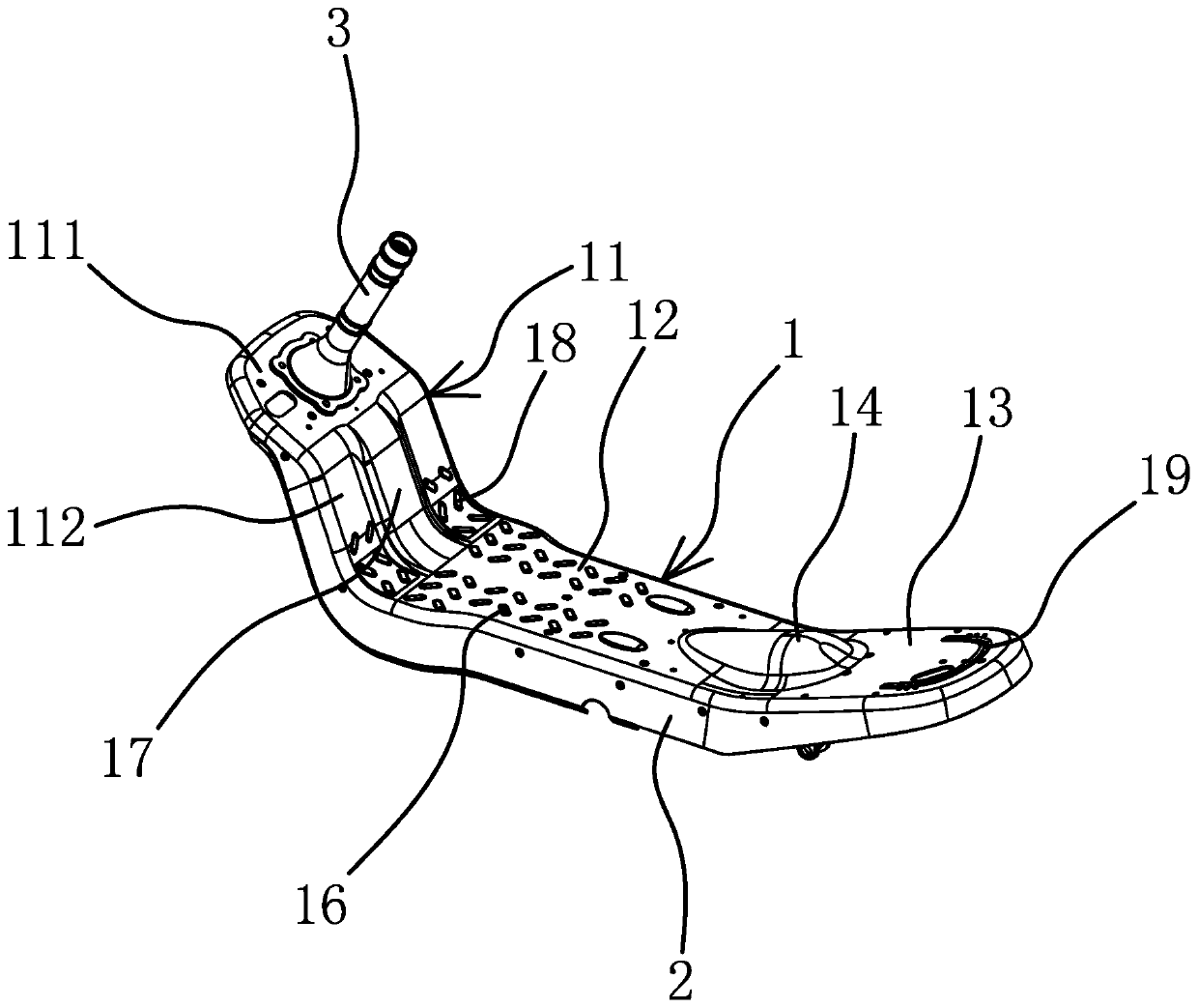

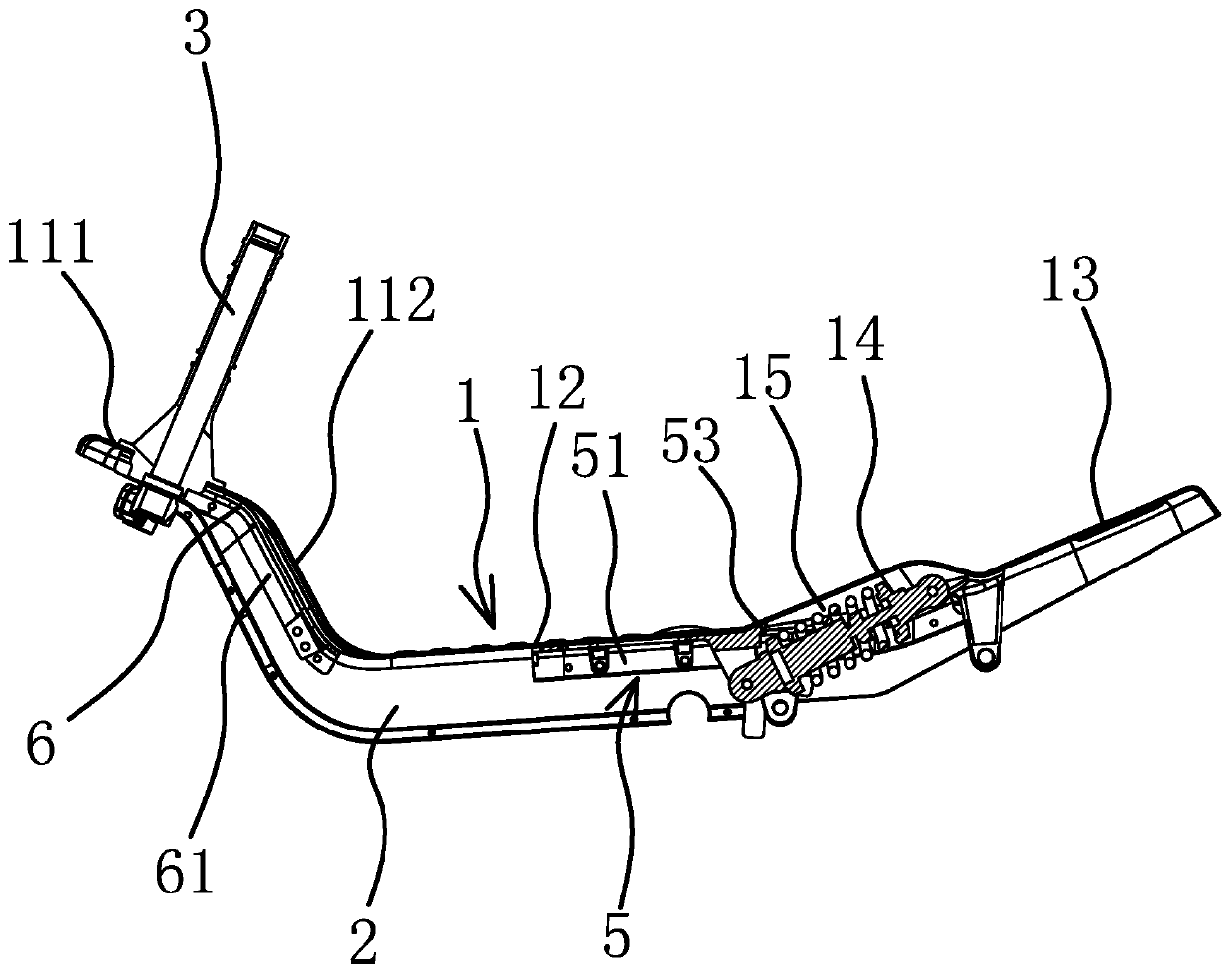

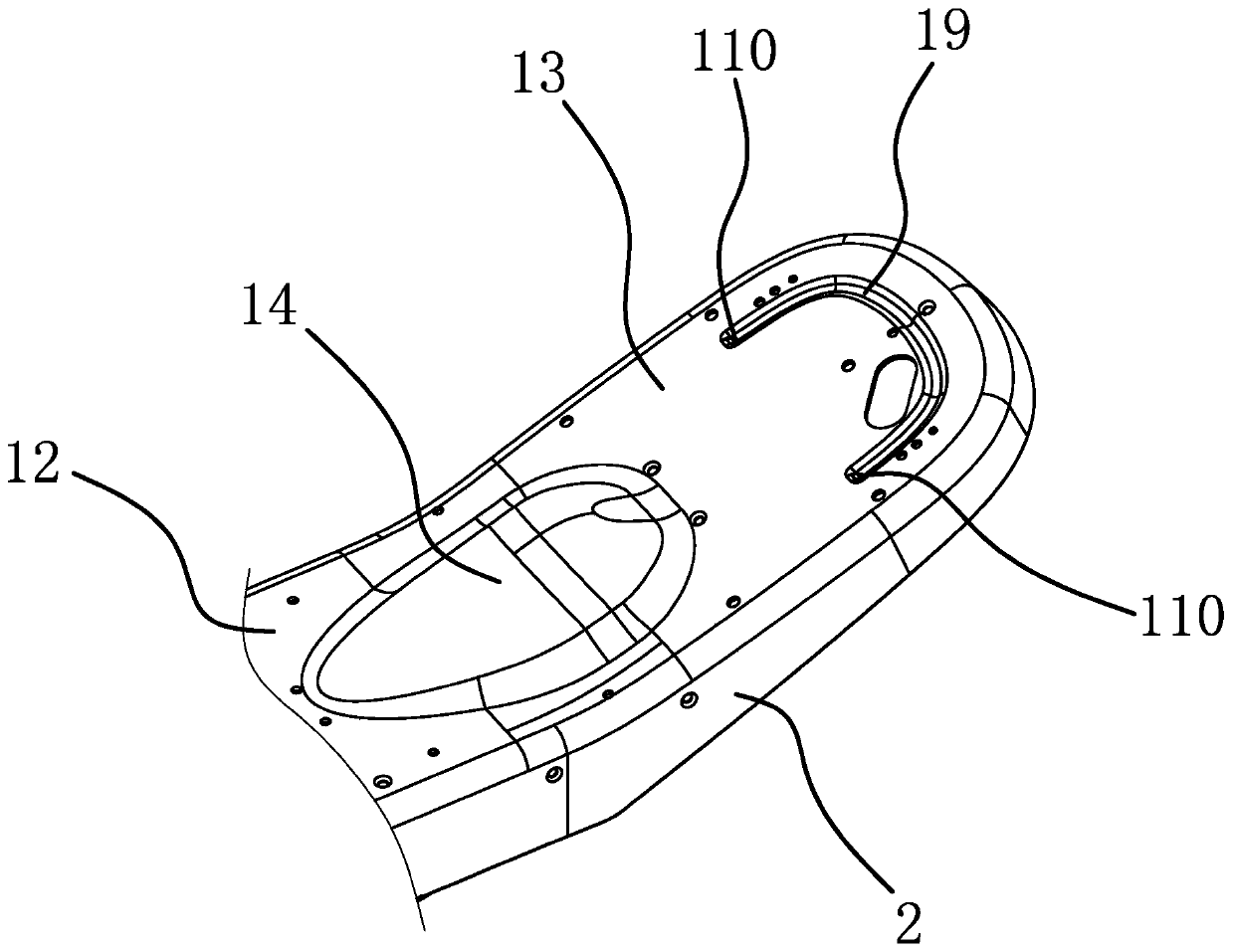

[0042] Such as figure 1 , Figure 4 and Figure 6 As shown, the electric vehicle frame includes a base plate 1 , a surrounding edge 2 , a faucet pipe 3 , a connecting plate 5 and a fixing plate 6 . The peripheral edge of the bottom plate 1 is bent downwards to form the surrounding edge 2, the bottom plate 1 and the surrounding edge 2 are made of aluminum alloy material and stamped integrally, and the bottom plate 1 and the surrounding edge 2 are of an integrated structure.

[0043] Along the front and rear directions of the electric vehicle, the base plate 1 includes a front end 11, a footrest 12 and a rear tail 13, the front end 11 includes a fixing part 111 and a connecting part 112, and along the vertical direction, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap