Pipeline typegarbageconveying system

A garbage and pipeline technology, which is applied in the direction of vertical pipelines, slideways, conveyor objects, etc., can solve the problem of buildings without garbage conveying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

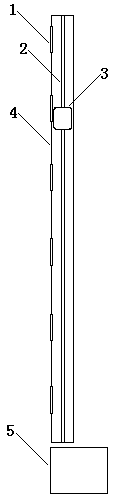

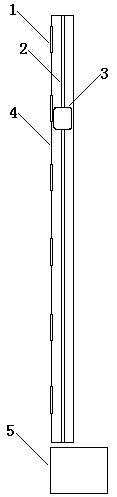

[0009] The pipe-type garbage conveying system consists of conveying pipes (4), operation buttons, microcomputer modules, power supply rails (2), conveying bins (3) and collection boxes (5). There is a program-controlled pipeline door (1) on each floor, the operation button is installed next to the program-controlled pipeline door, two power supply rails are installed in parallel in the transmission pipeline, and a pressure sensor is installed on the power supply rail where the program-controlled pipeline door is located , the power supply rail is connected to the power supply, and the upper and lower parts of the transmission warehouse are respectively equipped with a program-controlled warehouse door. There are multiple stepping motors on the transmission warehouse. The rotating shaft of the stepping motor is equipped with rollers, and the rollers are close to the power supply rail. There are two brushes on the transmission bin, each brush is close to a power supply rail, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com