RGV bidirectional telescopic fork and RGV

A telescopic and telescopic fork technology, applied in the field of intelligent logistics, can solve the problems of unstable telescopic transmission, inability to pick and place goods, waste of workshop space, etc., and achieve the effect of saving manpower and material resources, improving efficiency, and saving floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

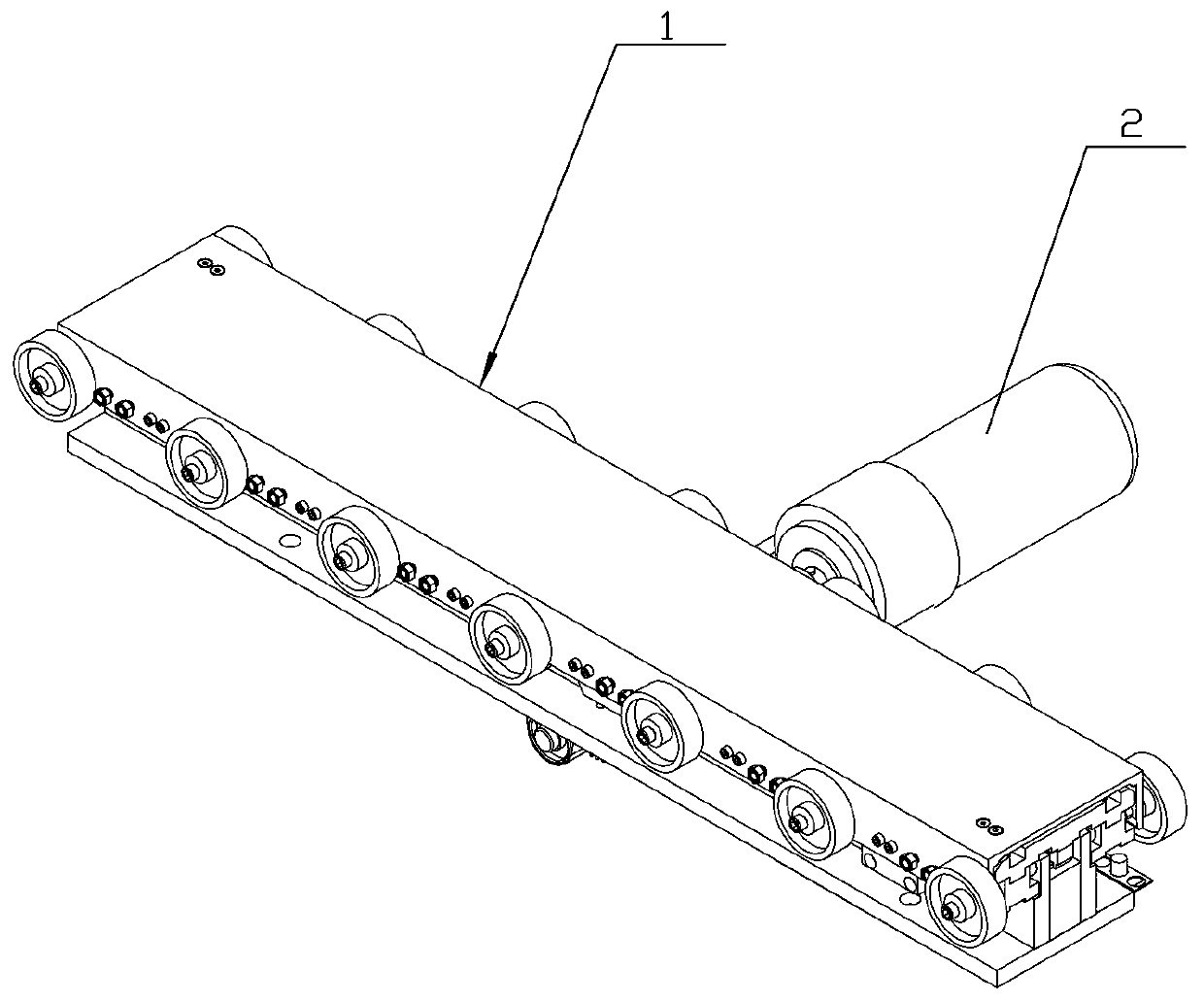

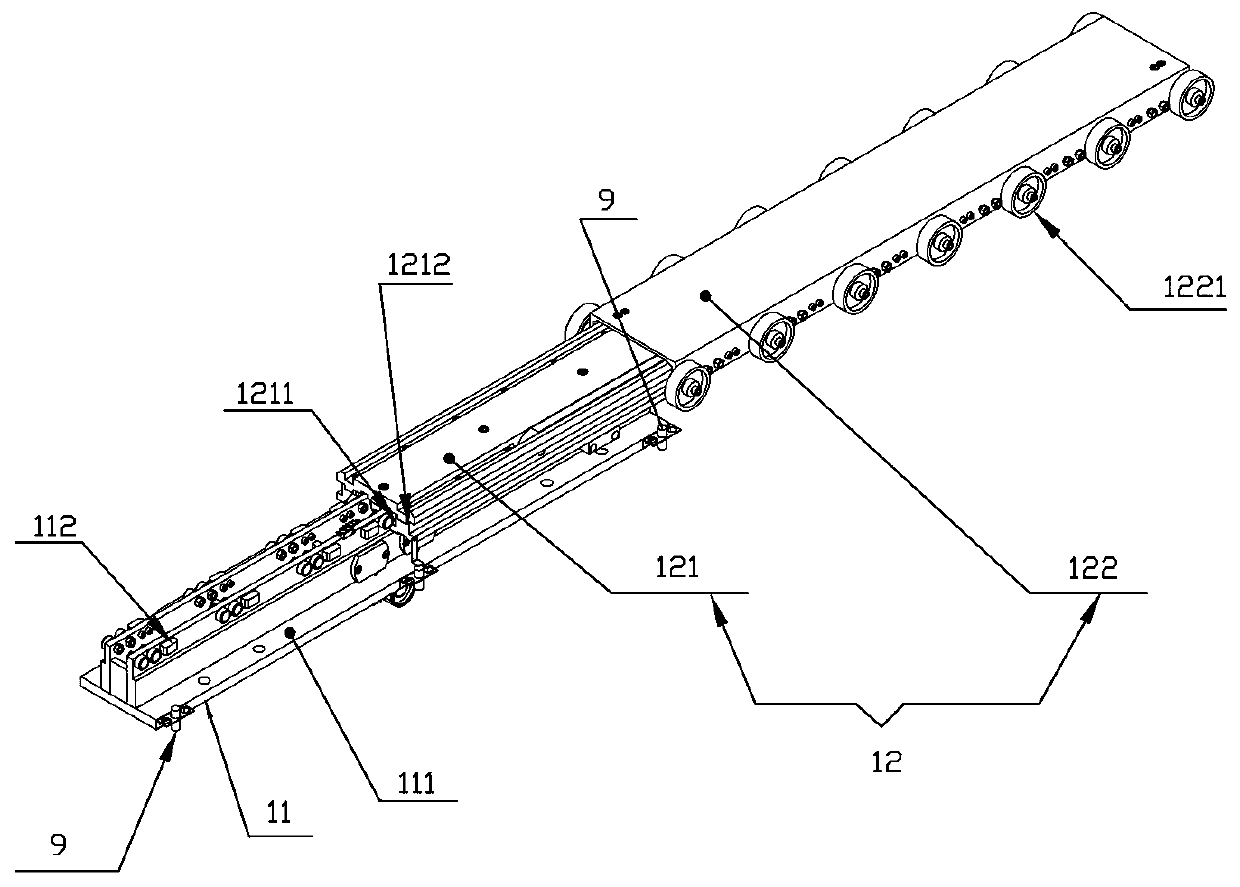

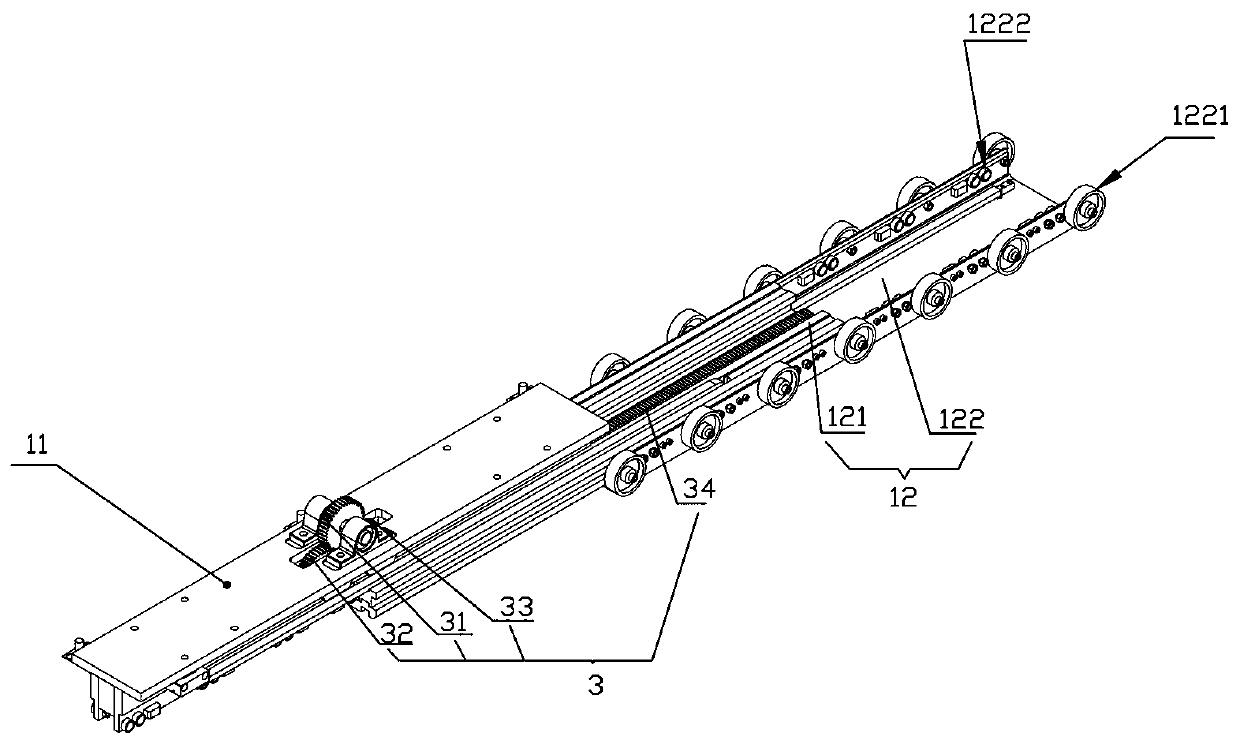

[0030] like figure 1 , 2 , 3 and 4, the RGV two-way telescopic fork of the present invention includes a fork body 1 and a drive mechanism 2, the drive mechanism 2 of this embodiment uses a motor, and the fork body 1 includes a fixed fork body 11 and the multi-stage telescopic fork body 12, the fixed fork body 11 and the multi-stage telescopic fork body 12 are slidingly connected, and the fixed fork body 1 and the multi-stage telescopic fork body 12 are connected by a transmission mechanism; on both sides of the fixed fork body 11 A support platform 111 is provided, and a supporting caster 1221 is provided on the side where the last fork body of the multi-stage telescopic fork body 12 corresponds to the support platform 111 . In this embodiment, the multi-stage telescopic fork body 12 adopts a two-stage telescopic fork body, including a first fork body 121 and a second fork body 122, the fixed fork body 11 and the first fork body 121 are slidably connected through the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com