A kind of preparation method of thermal paper sensitizer benzyl-2-naphthyl ether

A technology of naphthyl ether and benzyl, which is applied in the field of preparation of thermal paper sensitizer benzyl-2-naphthyl ether, can solve the problem of high price of 2-naphthol, achieve production cost reduction and great implementation value and socioeconomic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

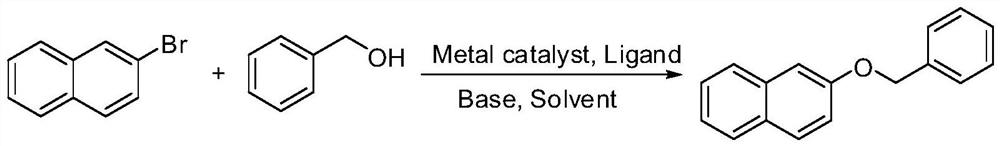

[0027] A kind of preparation method of thermal paper sensitizer benzyl-2-naphthyl ether comprises the following steps:

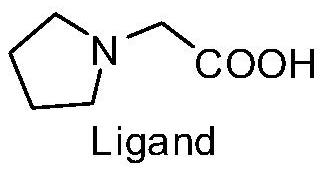

[0028] S1. Add 20.7 grams of bromonaphthalene (100 mmol) and 47 ml of DMF to a three-necked flask, stir well, and then add 12.7 grams of sodium carbonate (120 mmol, 1.2 equivalents), 1.9 grams of cuprous iodide (10 mmol, 0.1 equivalents), 1.55 grams of N - Tetrahydropyrrole acetic acid (12mmol, 0.1 equivalents) and 12.9 grams of benzyl alcohol (120 mmol, 1.2 equivalents);

[0029] S2, the reaction mixture was stirred overnight at 100°C;

[0030] S3, add 100ml of water and 100ml of toluene after recovering DMF under reduced pressure, extract the aqueous phase with 300ml of toluene three times, combine the organic layers, wash with water and 5% sodium carbonate successively;

[0031] S4. The organic phase was dried with anhydrous sodium sulfate, filtered, decolorized by silica gel and activated carbon, and the organic solvent was evaporated to obtain 25 grams...

Embodiment 2

[0033] The metal catalyst is 1.43 grams of cuprous bromide (10 mmol, 0.1 equivalent), and the other steps and consumption are the same as in Example 1.

[0034] After the crude product was recrystallized, 20.1 g of the product was obtained with a yield of 86% and a purity of more than 99%.

Embodiment 3

[0036] A kind of preparation method of thermal paper sensitizer benzyl-2-naphthyl ether comprises the following steps:

[0037] S1. Add 20.7 g of bromonaphthalene (100 mmol) and 47 ml of toluene into a three-necked flask, and stir. Add 12.7 grams of sodium carbonate (120 mmol, 1.2 equivalents), 1.9 grams of cuprous iodide (10 mmol, 0.1 equivalents), 1.55 grams of N-tetrahydropyrrole acetic acid (12 mmol, 0.1 equivalents) and 12.9 grams of benzyl alcohol (120 mmol, 1.2 equivalents) in sequence. );

[0038] S2, the reaction mixture was stirred overnight at 100°C;

[0039] S3, after cooling to room temperature and layering toluene, add 100ml of water and 53ml of toluene, extract the aqueous phase with 300ml of toluene three times, combine the organic layers, and wash with water and 5% sodium carbonate successively;

[0040] S4. The organic phase was dried with anhydrous sodium sulfate, filtered, decolorized by silica gel and activated carbon, and the organic solvent was evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com