Bainite steel with high strength and elongation and preparation method and application of bainite steel

A technology of bainite steel and high-strength plastic product, which is applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of long production process, high-strength plastic product cannot be achieved, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

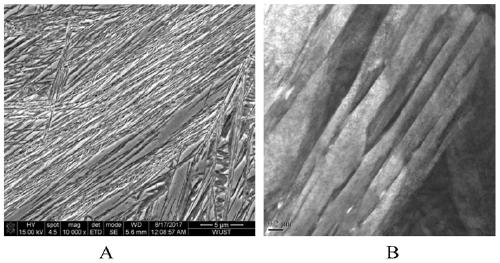

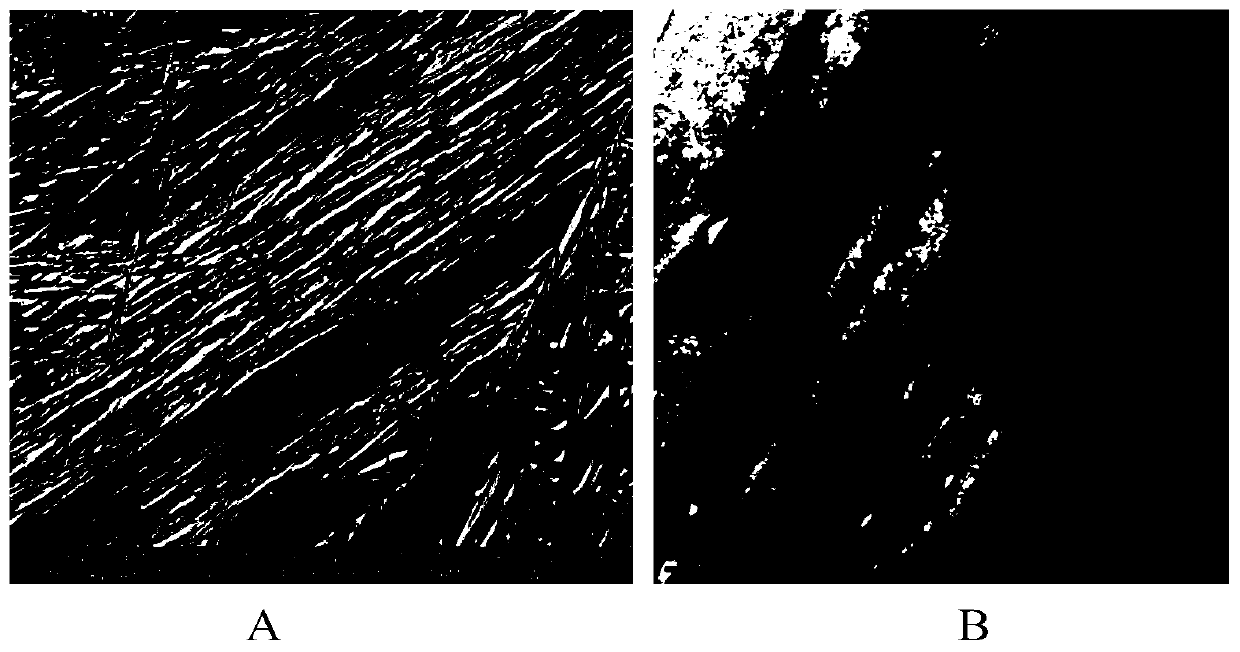

Image

Examples

Embodiment 1

[0053] The main process flow of the preparation method of the bainite steel with high strength and plastic product provided in this example is as follows: hot metal desulfurization→converter blowing→argon blowing→refining→thin slab continuous casting→soaking→seven-stand finish rolling→layer Flow cooling → coiling → primary annealing → secondary annealing. Among them, the processes of molten iron removal, sulfur converter blowing and argon blowing are conventional technologies.

[0054] The rest of the process steps are as follows:

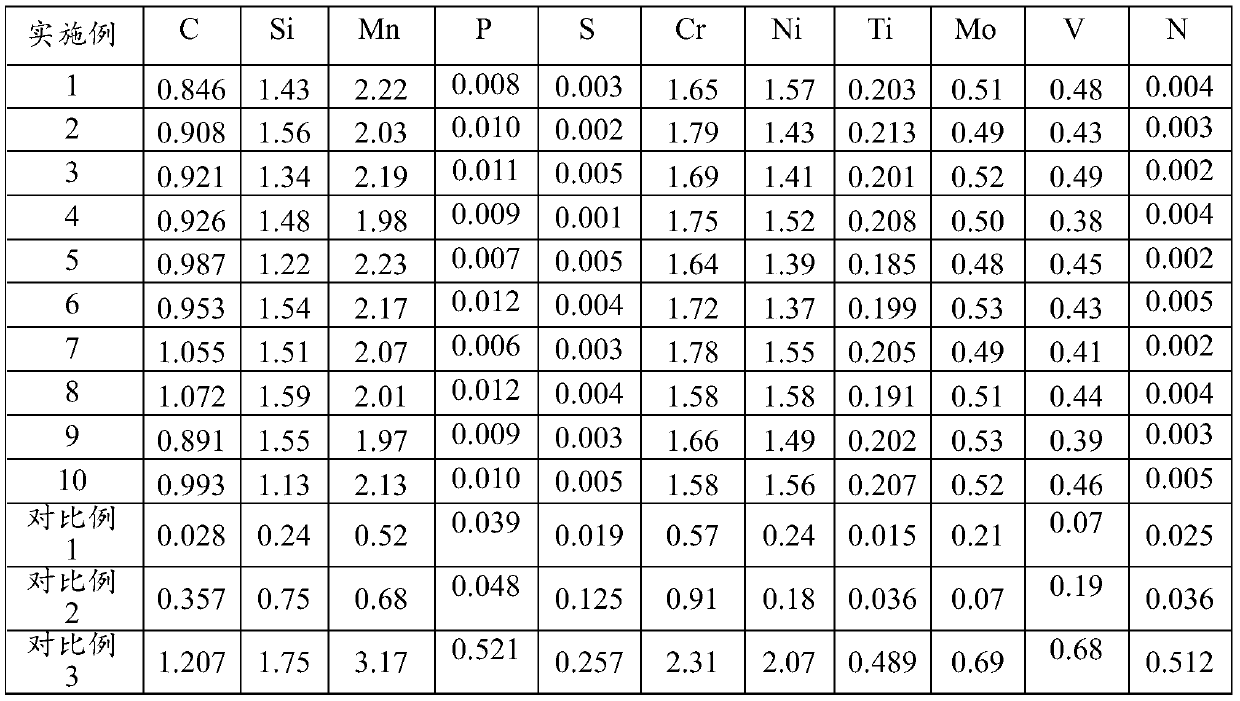

[0055] (1) The chemical composition range of molten steel after alloying treatment in the refining process is C: 0.846-1.072%, Si: 1.13-1.59%, Mn: 1.97-2.23%, P: ≤0.012%, S: ≤0.005%, Cr: 1.58-1.79%, Ni: 1.37-1.58%, Ti: 0.185-0.213%, Mo: 0.48-0.53%, V: 0.38-0.49%, N: ≤0.005%, and the rest are Fe and unavoidable impurities.

[0056] In this embodiment, the chemical composition range of molten steel is C: 0.846%, Si: 1.43%, Mn: 2.22%, P: ≤0.008%, S:...

Embodiment 2-10

[0076] The preparation method of the high-strength bainitic steel provided in Examples 2-10 is basically the same as that of Example 1, except that the content of elements and related parameters are different. See Table 1 and Table 2 for the differences.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com