Dredging device and dredging method for blockage of slag fall pipe of circulating fluidized bed boiler in biomass power plant

A technology of circulating fluidized bed and slag falling pipe, which is applied in the direction of combustion method, combustion product treatment, solid residue removal, etc. It can solve the problems of large slag and coke block blockage, many impurities, and easy slagging of bed materials, etc. Reach the requirement of reducing high temperature resistance performance, high degree of intelligence, convenient and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

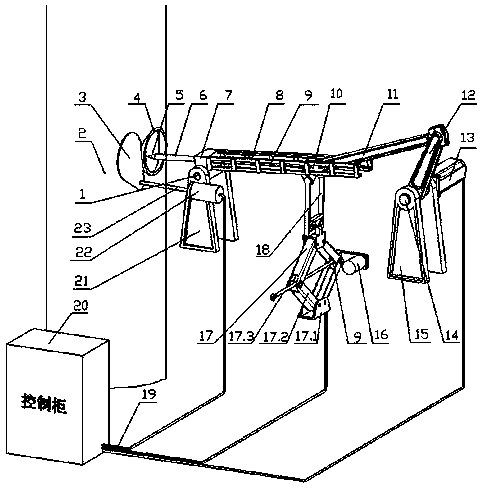

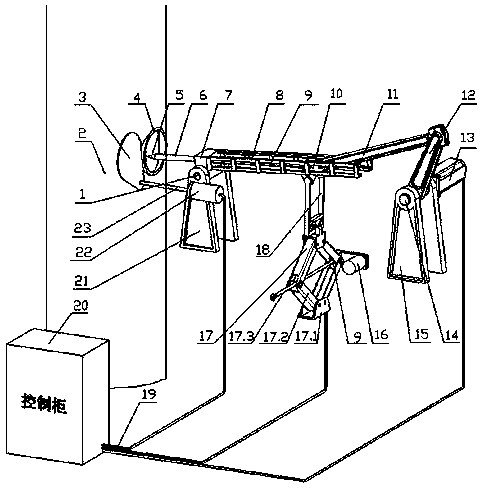

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as figure 1 As shown, a dredging device for clogging of a slagging pipe of a circulating fluidized bed boiler in a biomass power plant of the present invention is provided with a dredging port 4 on the slagging pipe 2, and the free end of the dredging device of the present invention extends in the dredging port 4, and Dredge the slag pipe 2.

[0037] The dredging device includes a sealing cover 3, a dredging rod 6, a guide rail bracket 7, a guide rail 8, a connecting rod 11, a crank 12, a dredging operation driving motor 13, an angle adjustment driving motor 16, an angle adjustment unit 17, a control cabinet 20, and a guide rail bracket fixing seat 21 and sealing cover driving motor 22.

[0038] One end of the guide rail bracket 7 is hinged on the guide rail bracket fixing seat 21 through the guide rail bracket fixing pin 1, the other end is supported on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com