Clean machining process of lycium chinense

A processing and cleaning technology is applied to the field of drying treatment technology for wolfberry, which can solve the problems of reducing the storage time of wolfberry, reducing the medicinal and edible value of wolfberry, and achieves convenient feeding, fast drying speed and time-consuming. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The clean processing technology of Chinese wolfberry, its steps are:

[0061] S1: Lycium barbarum is cleaned by the cleaning device 100;

[0062] S2: the washed wolfberry is preliminarily dried by the drying device 200 and water drops are removed;

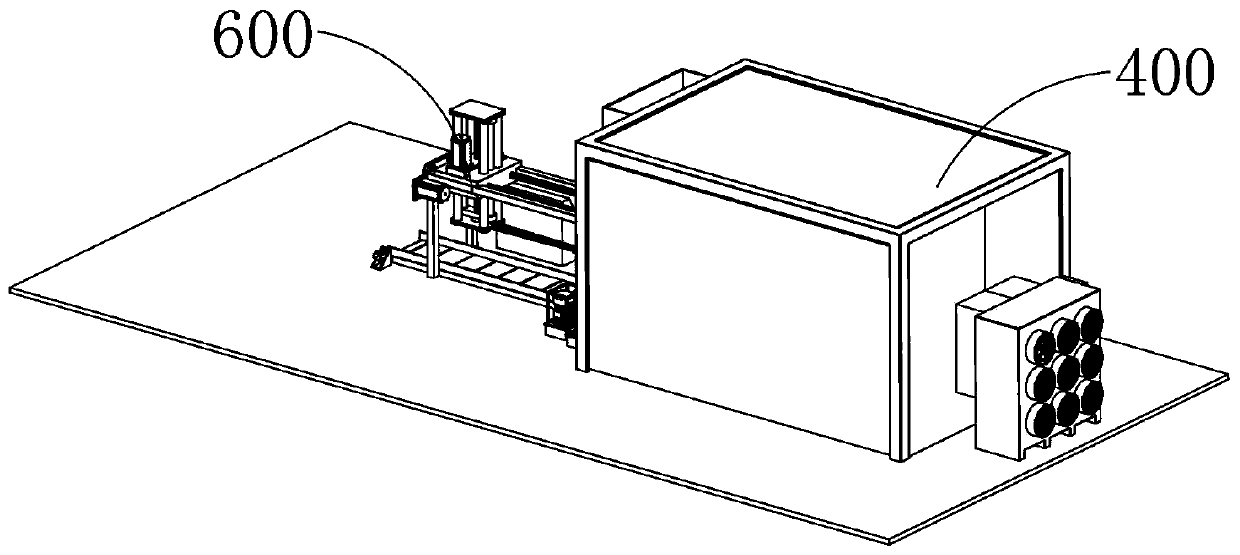

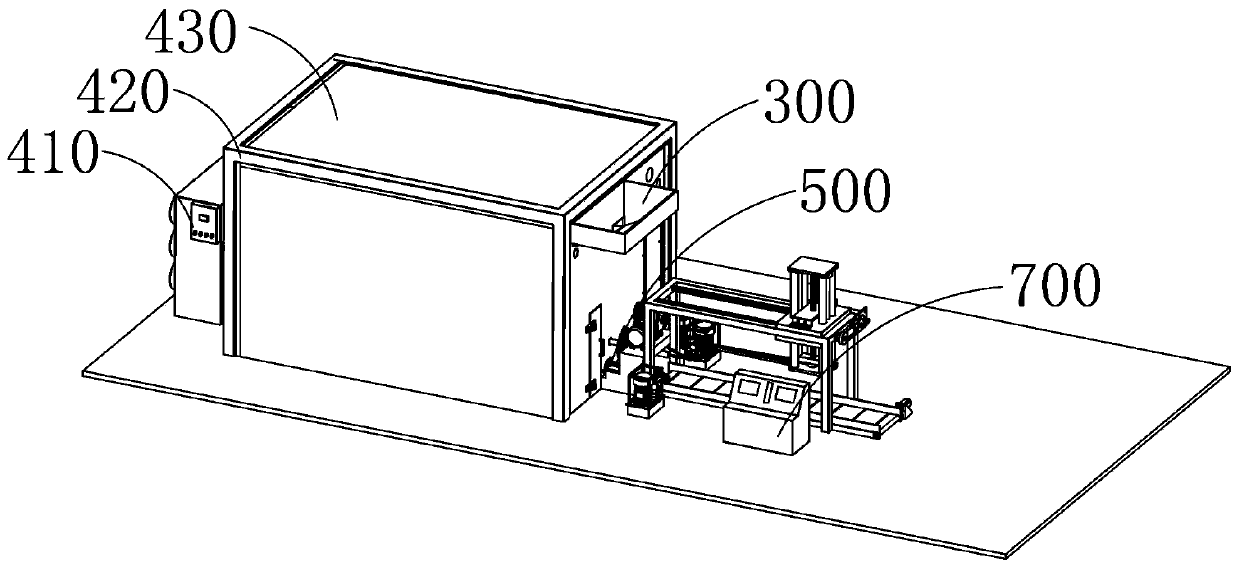

[0063] S3: the dried wolfberry is transported to the drying device 400 through the feeding device 300;

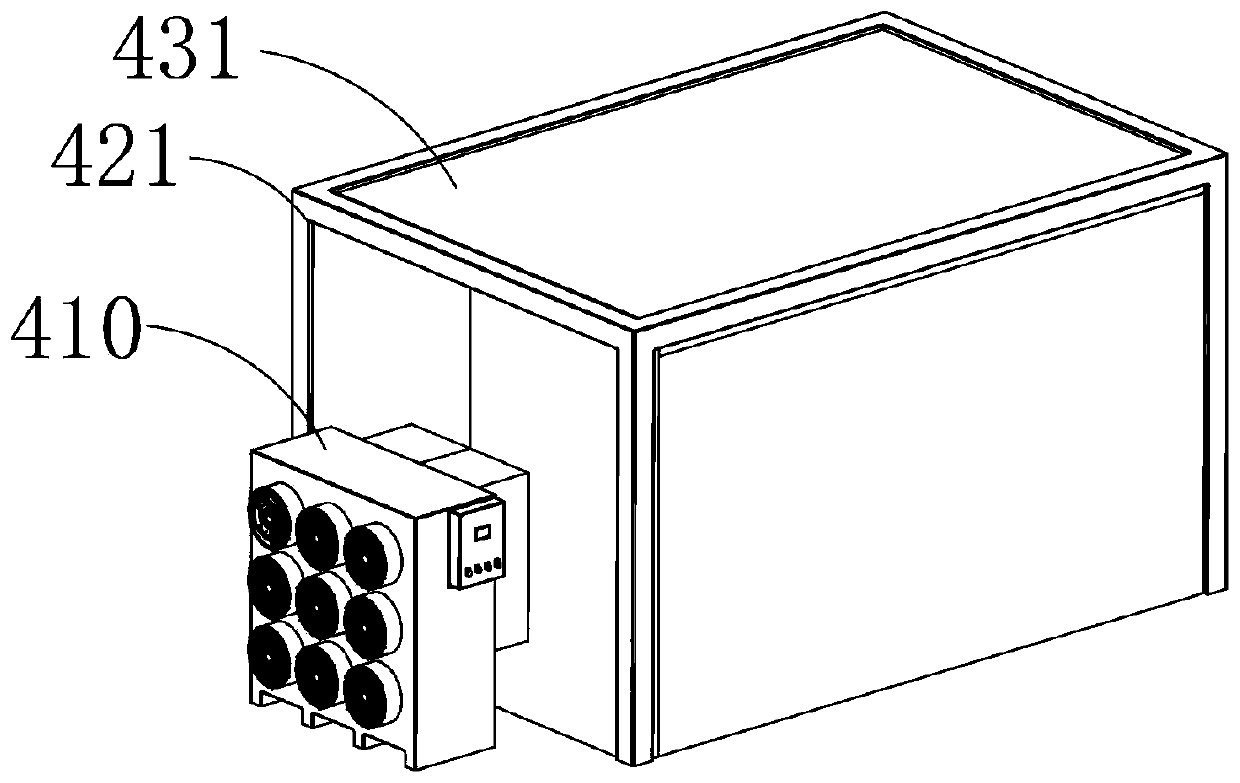

[0064] The washed and dried Chinese wolfberry is transported to the feed tank 428 through the feed funnel 310 and the feed pipeline 320, and then the operation of the closed hydraulic pump 353 is controlled by the console 700, and finally the closed telescopic member 352 is used to make the closed plate 351 pair with the feed funnel. 310 is closed at the connection point of the feeding pipeline 320, and then the drying hot air blower 410 runs and provides the hot air used for drying wolfberry for the drying box 420, and the wolfberry is dried in the drying box 420;

[0065] S4: The feeding device 300 also includes a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com