Rotor pneumatic load analysis method based on actually measured structural load

An analysis method and aerodynamic load technology, applied in the field of flight test, can solve the problems of little experience in rotor aerodynamic load analysis technology, stop and so on, and achieve the effect of reliable helicopter rotor aerodynamic analysis law

Active Publication Date: 2019-07-05

CHINESE FLIGHT TEST ESTAB

View PDF4 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the analysis technology of helicopter rotor aerodynamic load at home and abroad mostly stays in theoretical model calculation or wind tunnel test, rotor tower and other environmental conditions, and there is little experience in the analysis technology of rotor aerodynamic load in the actual flight test process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0047] A rotor aerodynamic load analysis method based on measured structural loads, the specific steps are as follows:

[0048] Step 1: the determination of helicopter rotor key structural load test parameters;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

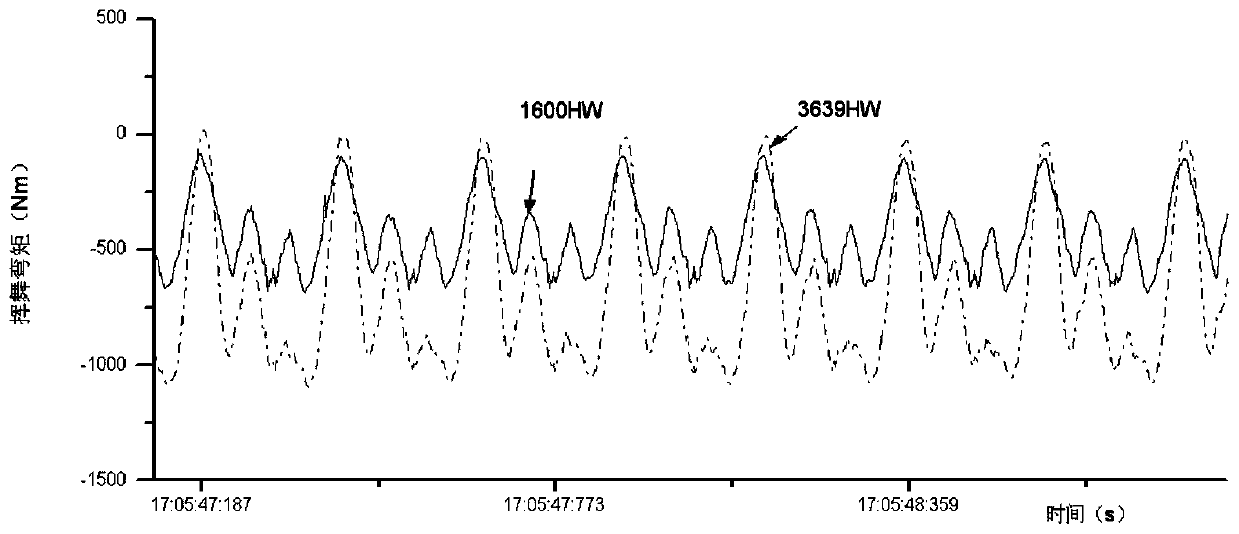

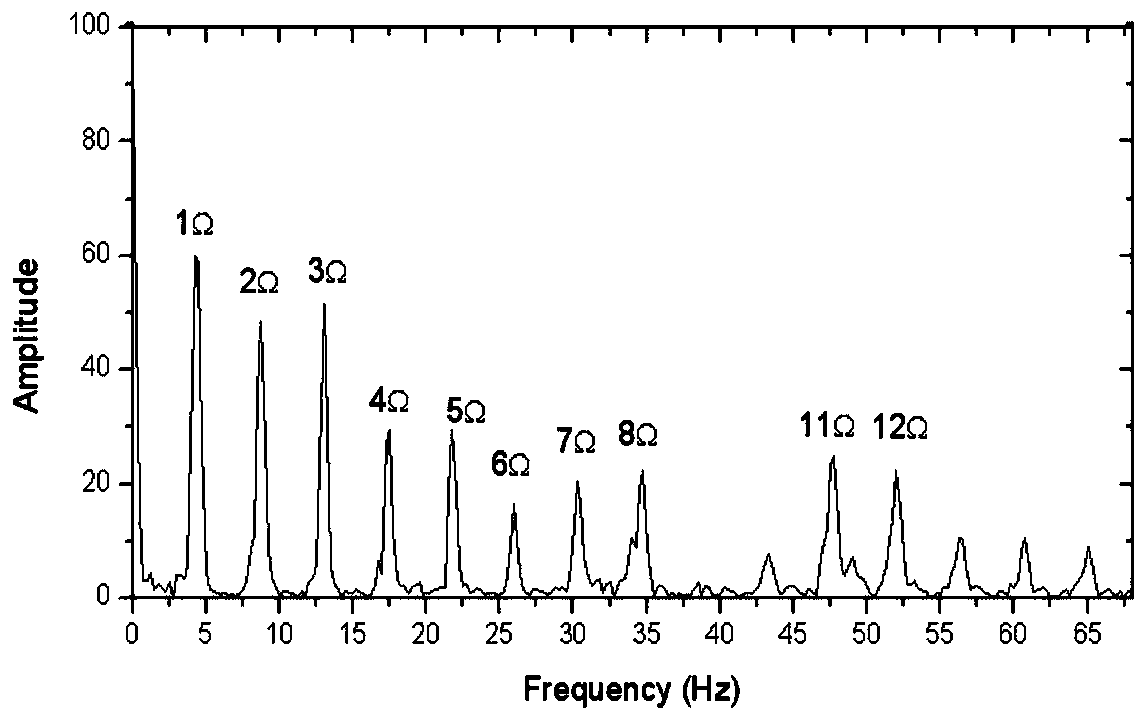

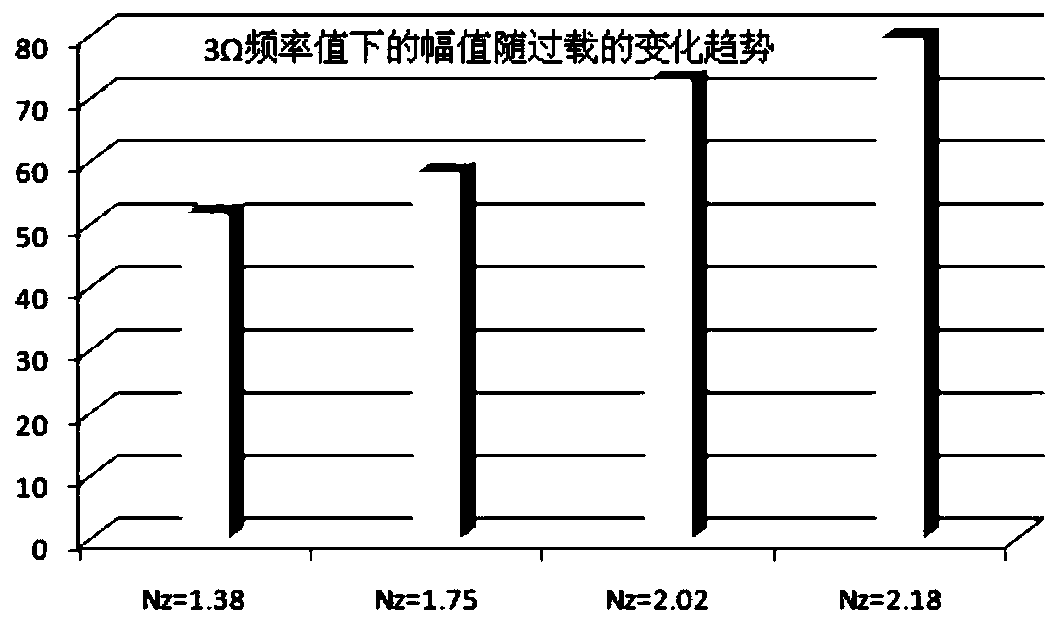

The invention discloses a rotor pneumatic load analysis method based on actually measured structural load, and belongs to the technical field of flight tests. The invention discloses a helicopter rotor working method. Measurement of the key structure load of the helicopter rotor is determined. The method comprises the following steps of carrying out resistance strain gauge installation and groundload calibration test on the strain gauge; testing and adding a key signal of rotor wing rotation; through flight tests in different states, carrying out statistical analysis on the actually measuredrotor structure load in the time domain and the frequency domain without focus on a plurality of assumptions in the helicopter theoretical model simulation process, Meanwhile, different from the aerodynamic environment simulation conditions such as pneumatic test and rotor tower test processes, the aerodynamic condition of the helicopter rotor can be reflected more truly, and a more reliable helicopter rotor aerodynamic analysis rule is obtained.

Description

technical field [0001] The invention discloses a rotor aerodynamic load analysis method based on measured structural loads and belongs to the technical field of flight tests. Background technique [0002] The helicopter rotor is not only the aerodynamic lifting surface during the flight of the helicopter, but also the control surface. It is of great significance to accurately grasp the change law of the aerodynamic load of the helicopter rotor, whether it is in the performance evaluation of the helicopter, or in the trim calculation and flight quality evaluation of the whole machine. In the actual flight test process, the aerodynamic load distribution of the rotor is also different for different flight test subjects in the helicopter flight spectrum. The rotor as the main vibration source of the helicopter will also reflect different vibration levels of the whole helicopter. Considering from the angle of view, it is more important to understand the distribution law of helic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

CPCG06F30/15G06F30/17Y02T90/00

Inventor 王泽峰宋日晓郑甲宏寇福军李永寿

Owner CHINESE FLIGHT TEST ESTAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com