Multi-objective optimization design method based on vehicle body section parameterization

A multi-objective optimization, cross-sectional parameter technology, applied in computing, mechanical equipment, electrical and digital data processing, etc., can solve the problem of inability to make accurate judgments on the impact of the overall performance of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

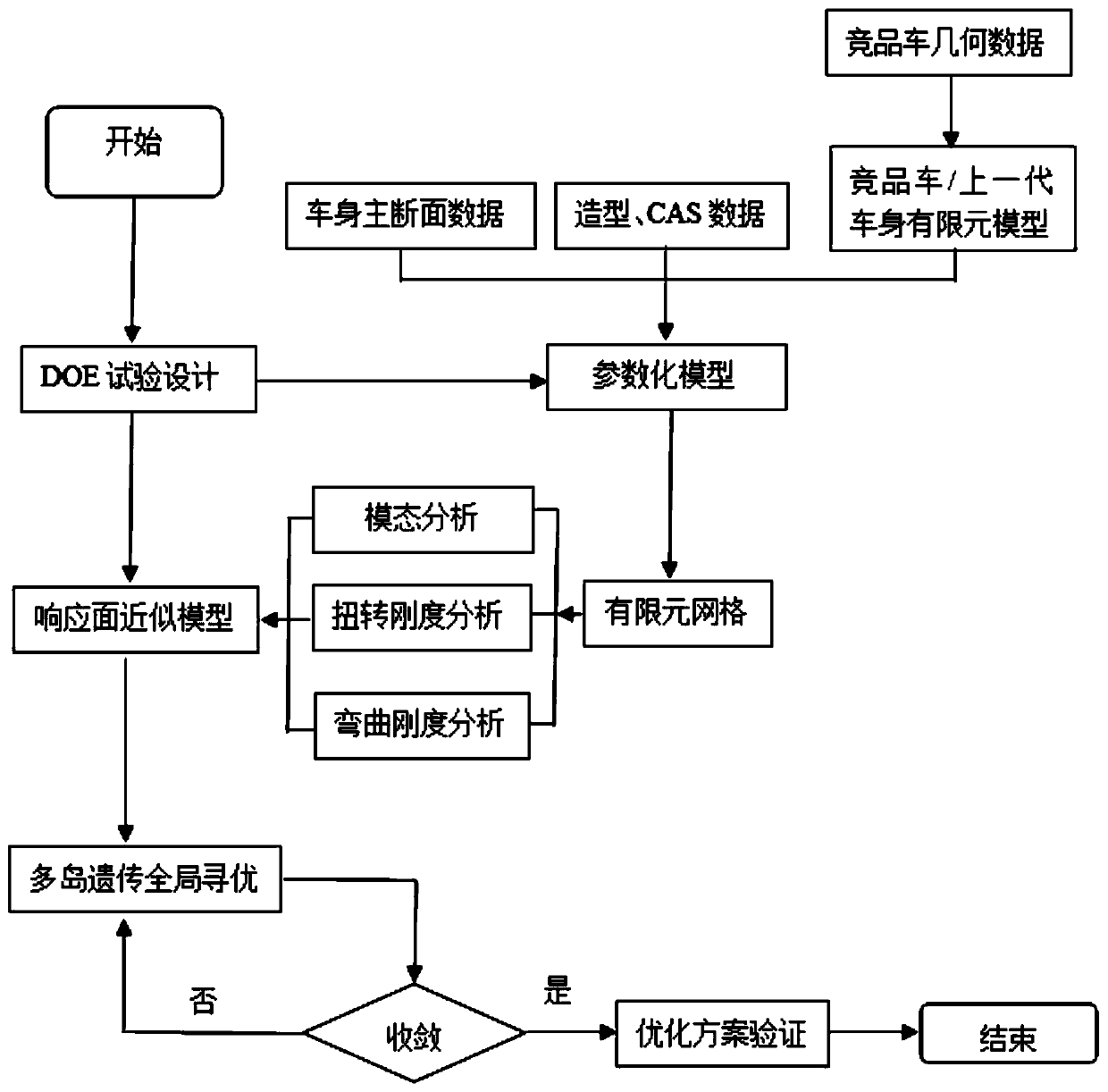

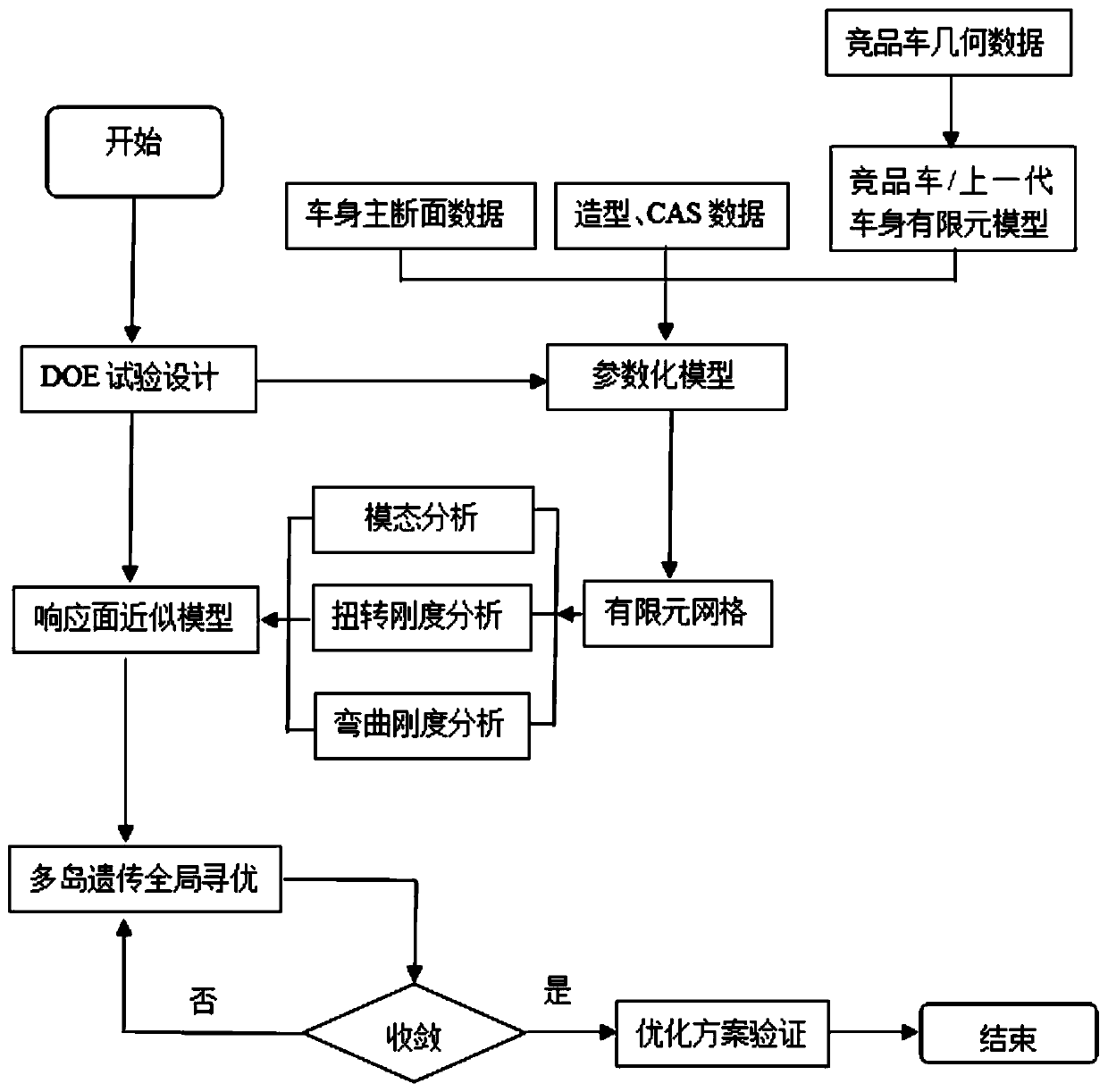

[0021] refer to figure 1 According to the invention, the parametric multi-objective optimal design method of the vehicle body section includes the parametric modeling of the vehicle body section and the multi-objective optimal design of the vehicle body section.

[0022] The parametric modeling of the body section includes the following steps:

[0023] The body design department inputs the main section data of the car body, and builds the parametric model of the car body joints based on the section data.

[0024] Obtain modeling and CAS data input, and establish a parametric model of the outer surface of the car body based on the modeling and CAS data.

[0025] Determine the geometric data or finite element mesh of competing models or previous-generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com