User-side energy equipment intelligent maintenance method

A technology on the user side and equipment, applied in the direction of data processing applications, instruments, character and pattern recognition, etc., can solve the problems of reducing the competitive advantage of operation and maintenance providers, high professional requirements for operation and maintenance personnel, and low user stickiness, so as to reduce system Operation and maintenance costs and equipment failure risks, and the effect of improving energy supply quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0039] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

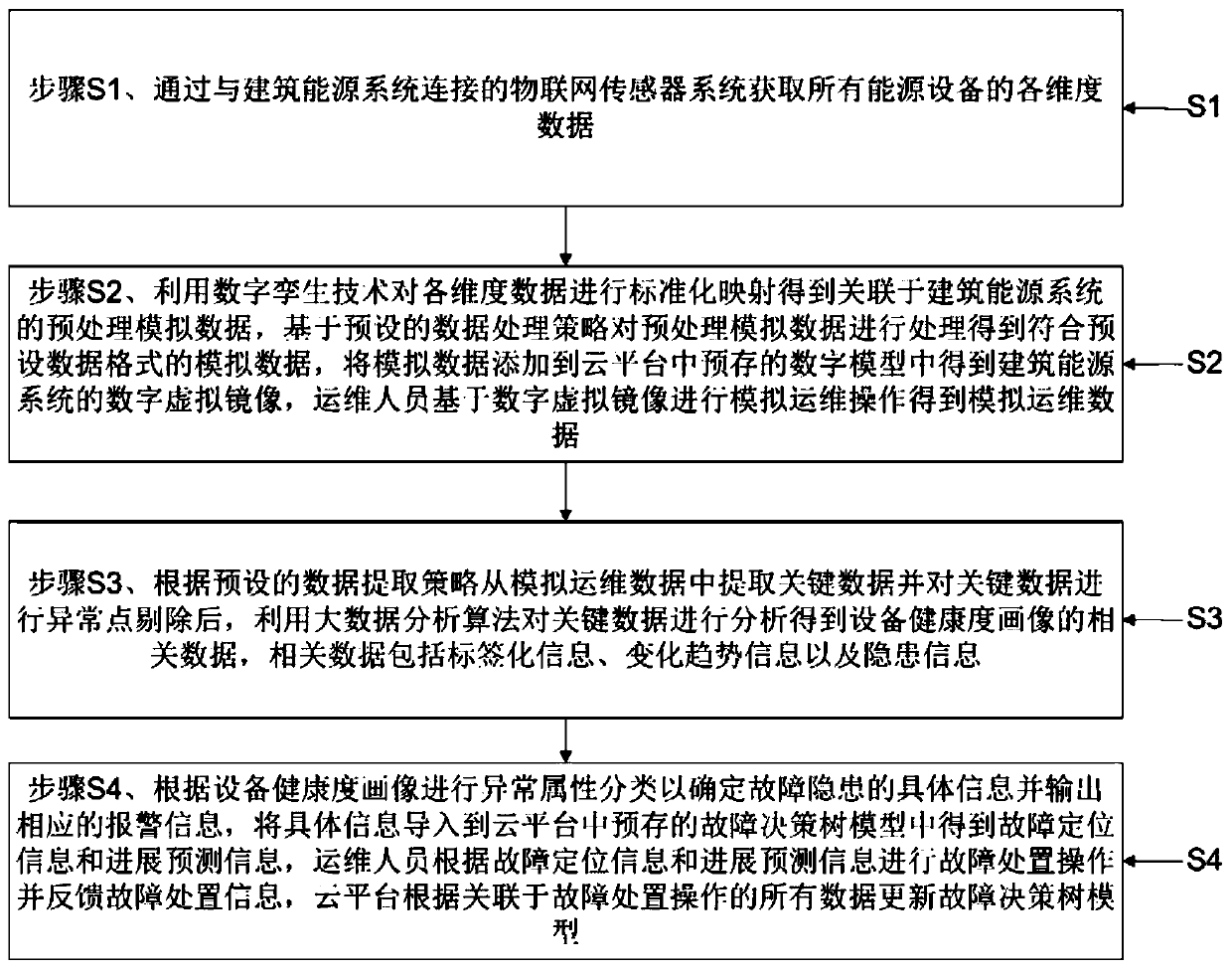

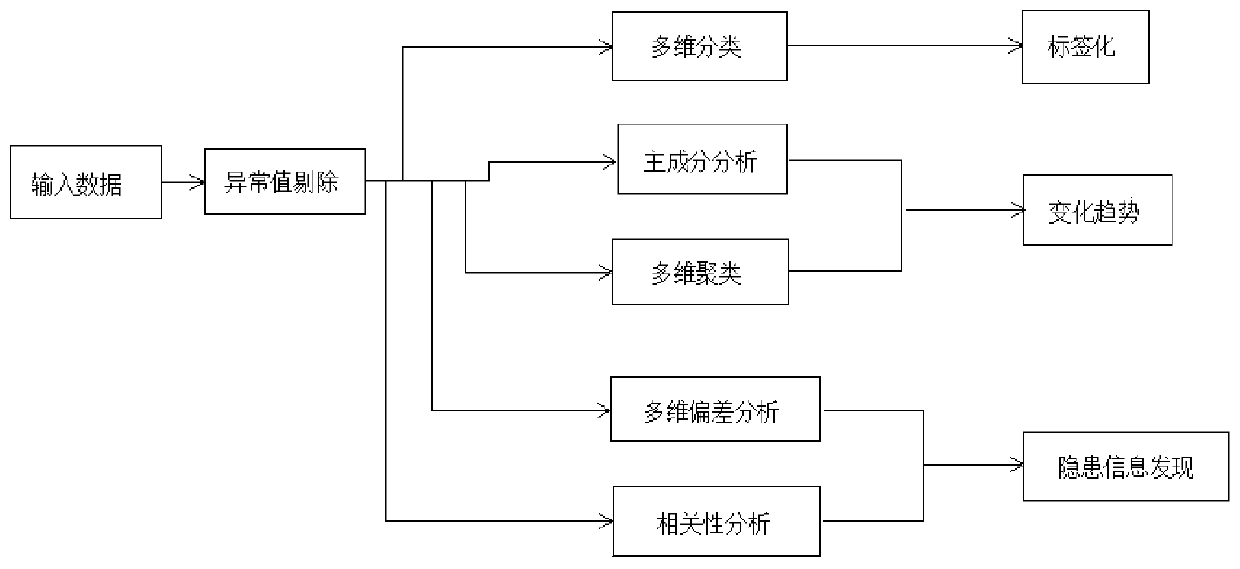

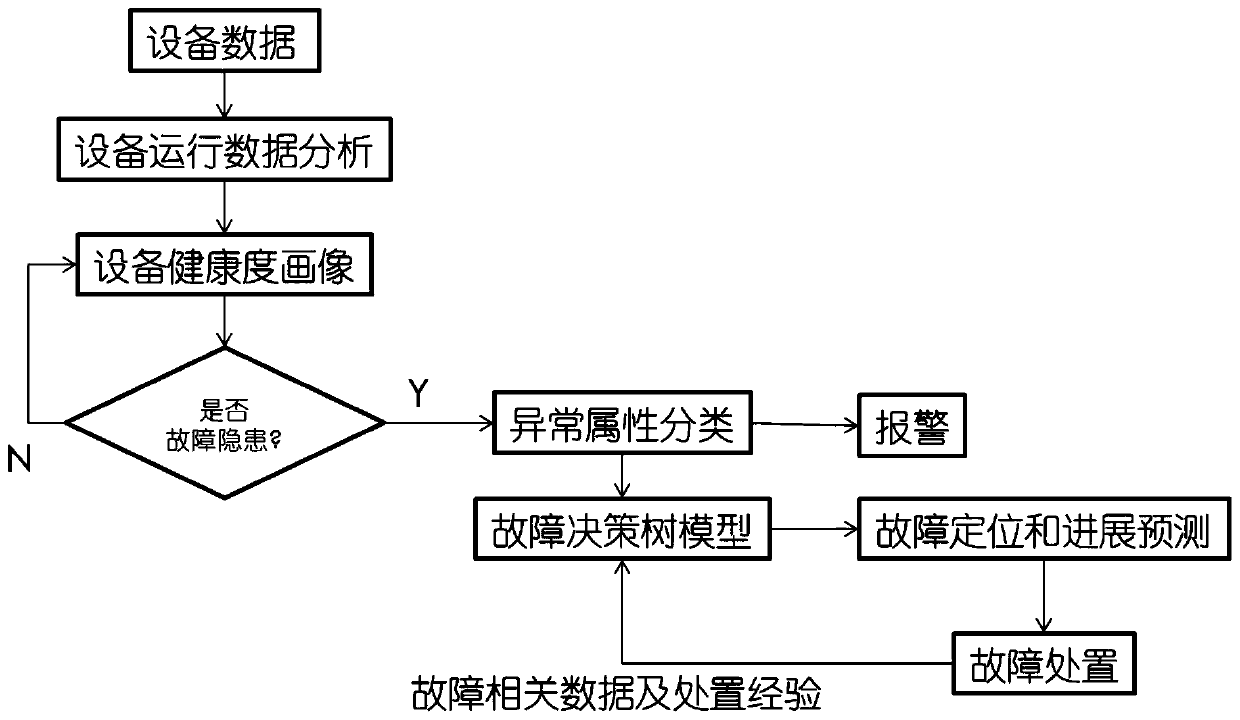

[0040] Such as Figure 1-3 As shown, a smart maintenance method for user-side energy equipment is applicable to building energy systems, where the building energy system includes multiple energy equipment; the above method includes:

[0041] Step S1. Obtain data of various dimensions of all the above-mentioned energy equipment through the Internet of Things sensor system connected to the above-mentioned building energy system;

[0042] Step S2. Using digital twin technology to perform standardized mapping on the above-mentioned dimensional data to obtain the pre-processed simulation data associated with the above-mentioned building energy system, and process the above-mentioned pre-processed simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com