Coiled lithium-ion battery pole piece

A lithium-ion battery, winding technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of surface coating stress concentration shedding, potential safety hazards, reducing battery energy density, etc., to increase volume capacity, improve Safety, high energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

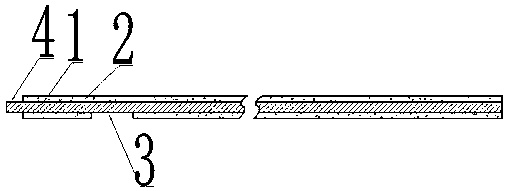

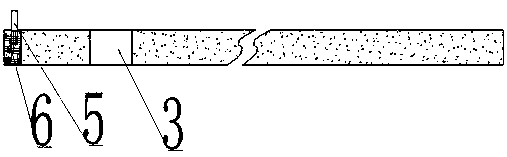

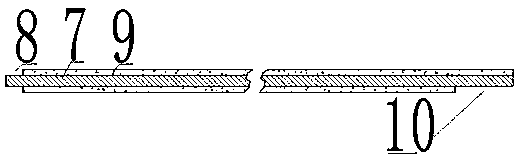

[0020] like Figure 1-Figure 4 The positive and negative sheets of a winding lithium ion battery shown include a positive electrode sheet and a negative electrode sheet, the positive electrode sheet includes a first current collector 1, and the first current collector 1 is coated with the first An active material 2; the first end of the positive electrode sheet is provided with a positive electrode ear position 4 with a length of 10mm, and the positive electrode ear position 4 is not coated with the first active material 2 on both sides, and the first set at a distance of 450mm from the positive electrode ear position One side of the fluid 1 is provided with an anti-folding position 3, the length of the anti-folding position 3 is 30 mm and the surface is not coated with the first active material 2, and the first current collector 1 is coated on both sides except the positive electrode ear position 4 and the anti-folding position 3 coated with a first active substance;

[0021...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com