Negative electrode piece, preparation method thereof, pouch lithium ion battery and preparation method thereof

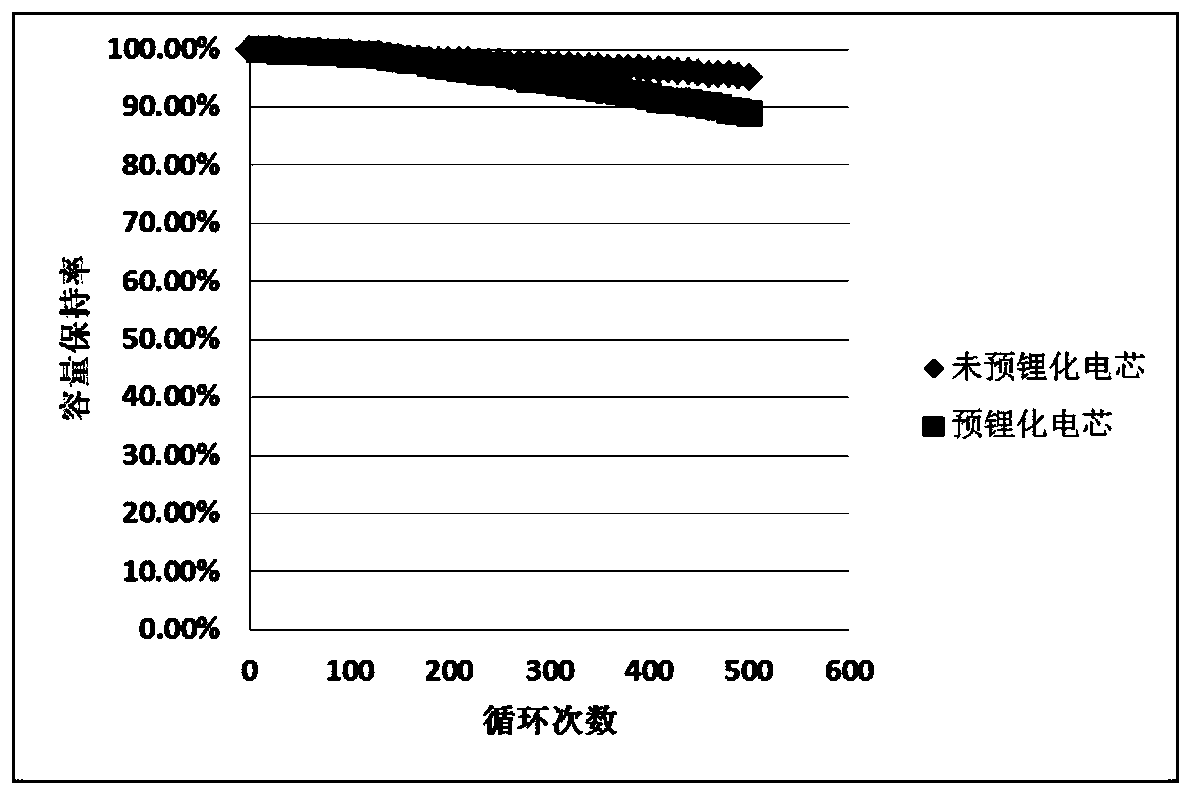

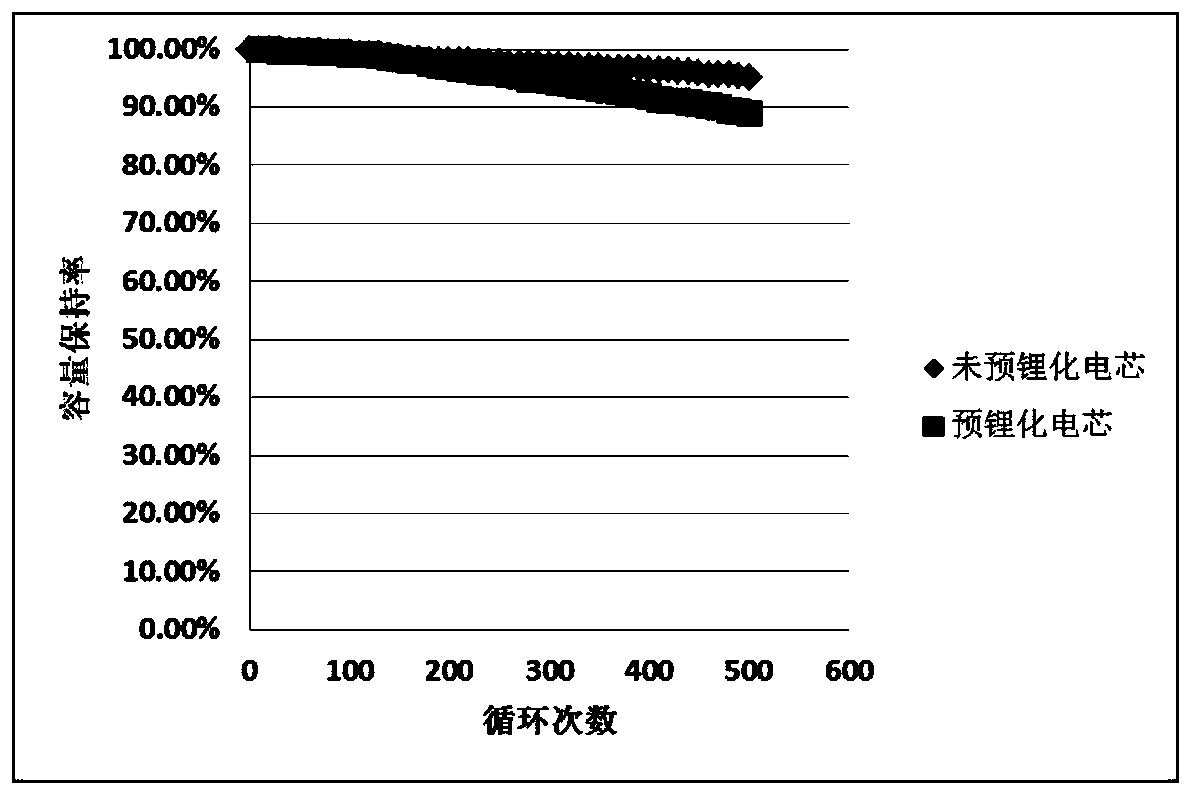

A technology of lithium ion battery and negative pole piece, applied in the direction of negative electrode, secondary battery, battery electrode, etc., can solve the problems of easy over-lithiation and lithium precipitation, so as to save processing cost, reduce the probability of lithium precipitation, and save Effects of Lithium Resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method for a soft pack lithium-ion battery, comprising the steps of:

[0052] (1) Preparation of the negative electrode sheet to be pre-lithiated: apply the silicon-carbon negative electrode slurry to the front and back surfaces of the negative electrode current collector, dry and then perform rolling to obtain the negative electrode sheet to be pre-lithiated.

[0053] (2) Pre-lithiation capacity design: Calculate the pre-lithiation capacity according to the irreversible capacity of the silicon-carbon anode, calculate the parameters of the porous lithium foil according to the obtained pre-lithiation capacity, and prepare the porous lithium foil.

[0054] Wherein, the shape of the porous lithium foil is circular, elliptical, rhombus, triangular, quadrangular or pentagonal, etc., and the preparation method of the pores of the porous lithium foil is piercing, pressing, corrosion, electrolysis or electroplating, etc. . The thickness of the porous lithium foil...

Embodiment 1

[0081] A preparation method for a soft pack lithium-ion battery, comprising the steps of:

[0082] Preparation of the negative electrode sheet to be pre-lithiated: the mixture of the negative electrode active material graphite and silicon (capacity C 负 =500mAh g -1 , the first Coulombic efficiency ICE=80%), the conductive agent Super P, the binder SBR and the thickener CMC are mixed according to the ratio of 90:4:3:3 to make a slurry, and the slurry is coated on a porous copper foil The positive and negative sides of the formed negative electrode current collector are dried, rolled, and cut to obtain a negative electrode sheet, and the surface density of the negative electrode sheet is ρ 负面 = 20 mg cm -2 , the area of the negative pole piece S 负面 =82cm 2 .

[0083] Pre-lithiation capacity design: pre-lithiation capacity C 设 It is designed to be 90% of the irreversible capacity of the silicon carbon negative electrode, and there is one negative electrode piece, C 设 = ρ...

Embodiment 2

[0091] A preparation method for a soft pack lithium-ion battery, comprising the steps of:

[0092] Preparation of the negative electrode sheet to be pre-lithiated: the mixture of the negative electrode active material graphite and silicon (capacity C 负 =500mAh g -1, the first Coulombic efficiency ICE=80%), the conductive agent Super P, the binder SBR and the thickener CMC are mixed according to the ratio of 90:4:3:3 to make a slurry, and the slurry is coated on a porous copper foil The positive and negative sides of the formed negative electrode current collector are dried, rolled, and cut to obtain a negative electrode sheet, and the surface density of the negative electrode sheet is ρ 负面 = 20 mg cm -2 , the area of the negative pole piece S 负面 =82cm 2 .

[0093] Pre-lithiation capacity design: pre-lithiation capacity C 设 It is designed to be 90% of the irreversible capacity of the silicon carbon negative electrode, and there is one negative electrode piece, C 设 = ρ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com