X-Y-axis antenna base and antenna system

An antenna base, X-Y technology, applied to antennas, folded antennas, antenna parts and other directions, can solve the problems of difficult to achieve rapid antenna adjustment, assembly, transportation and locking, inconvenient installation and transportation, large moment of inertia, etc., to achieve simple servo control. Reliable, low assembly difficulty, and the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

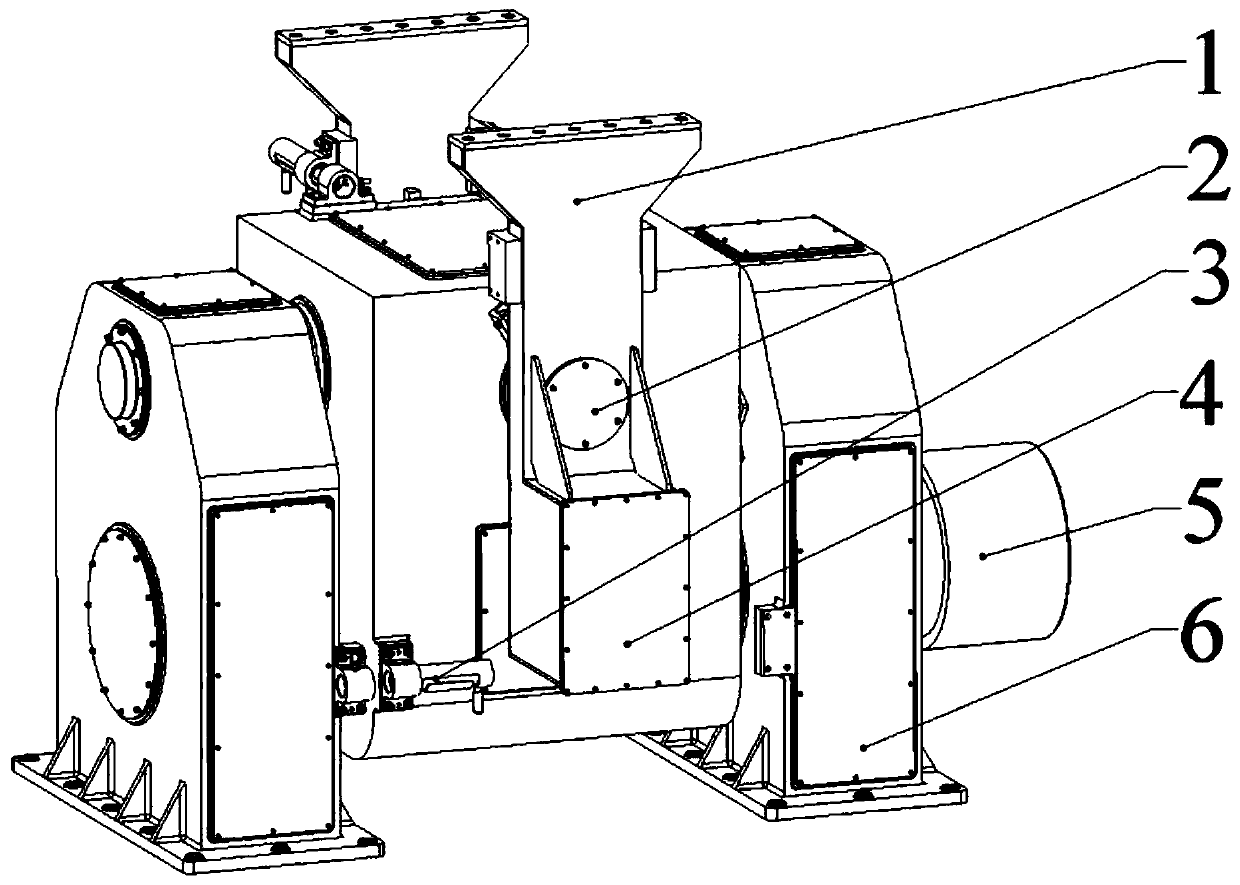

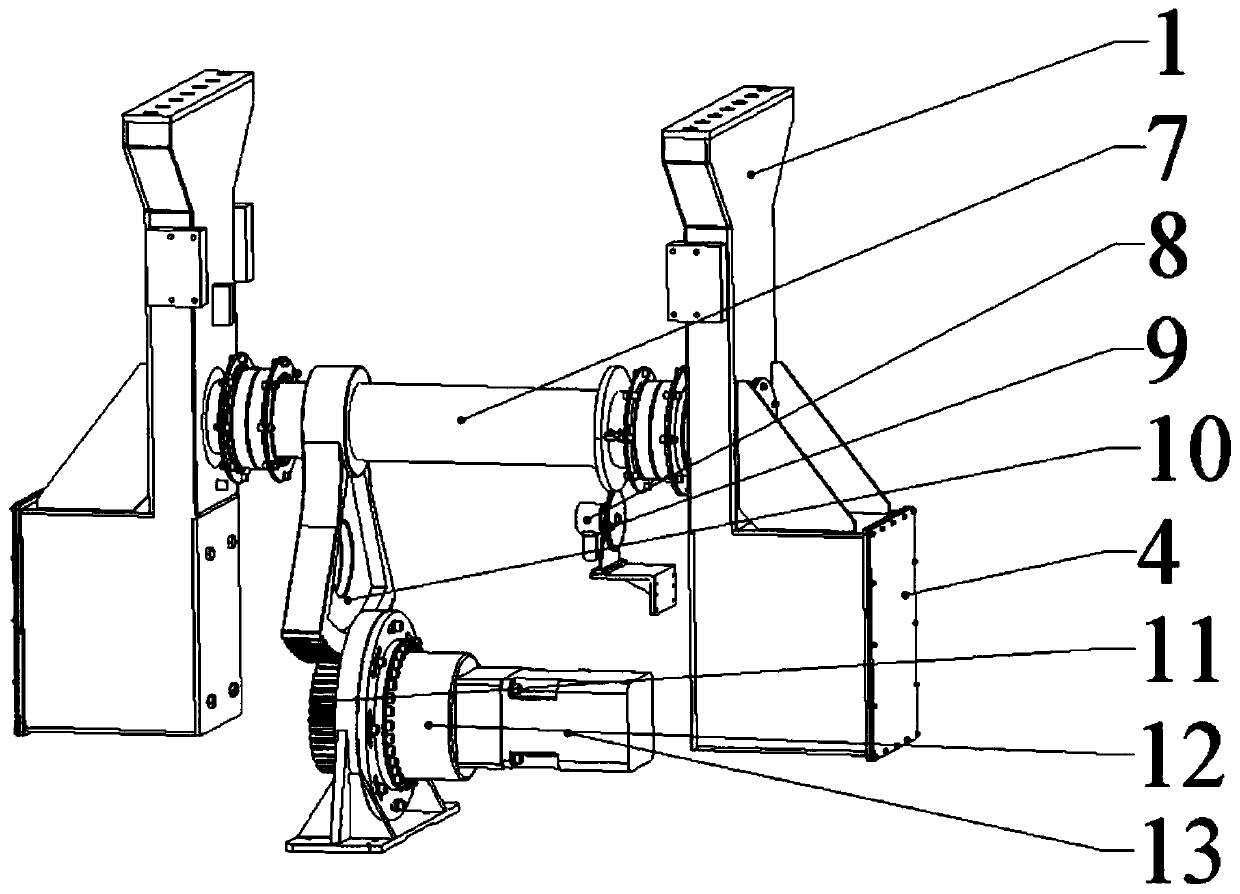

[0030] like figure 1 as shown, figure 1 It is the overall structural diagram of the X-Y antenna base of the present invention; the X-Y antenna base of the present invention includes an X-axis mechanism 5 and a Y-axis mechanism 2, and the X-axis mechanism 5 and the Y-axis mechanism 2 are fixedly connected, so The Y-axis mechanism 2 is fixedly provided with a support arm 1, and the X-Y antenna base is connected with the antenna mechanism through the support arm 1; the X-axis mechanism 5 includes an X-axis 19 and a first braking module; the Y-axis The mechanism 2 includes a Y-axis 7 and a second braking module, and the X-axis 19 and the Y-axis 7 are arranged orthogonally and coplanarly. The first brake module controls the rotation state of the X-axis 19; the second brake module controls the rotation state of the Y-axis 7; the X-axis 19 is fixedly connected to the Y-axis mechanism 2, and the The X-axis 19 can drive the Y-axis mechanism 2 to rotate, and the Y-axis 7 can drive the...

Embodiment 2

[0035] The X-Y antenna base includes the support arm 1 , the Y-axis mechanism 2 , the counterweight 4 , the X-axis mechanism 5 , and a base 6 .

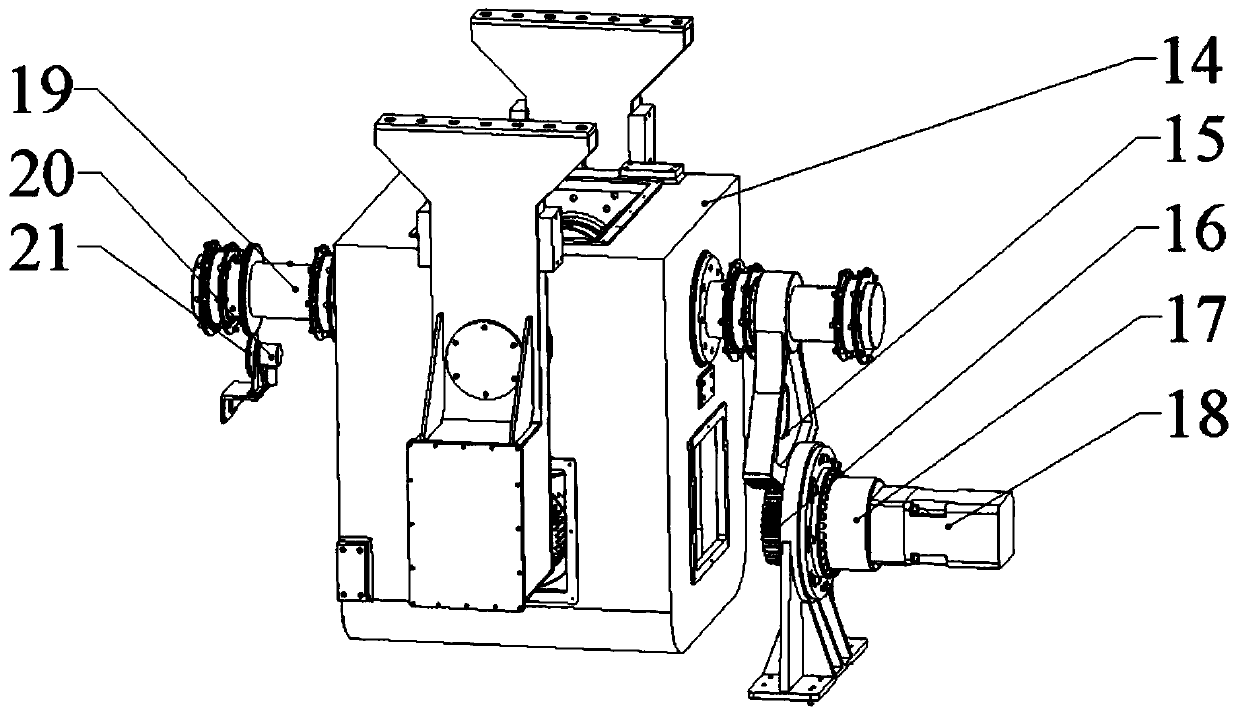

[0036] like figure 2 , image 3 , Figure 4 as shown, figure 2 is a structural view of the X-axis mechanism 5; image 3 is a structural view of the Y-axis mechanism 2; Figure 4It is a positional view of the X-axis 19 and the Y-axis 7; the first braking module includes a first rotating gear 15, a first driving gear 16, a first speed reducer 17, a first motor 18, a first double A piece gear 20, a first encoder 21; the second braking module includes a turntable 14, a second double-piece gear 9, a second rotating gear 10, a second drive gear 11, a second speed reducer 12, and a second motor 13 , the second encoder 8 .

[0037] The base 6 is symmetrically arranged on both sides of the Y-axis mechanism 2, and the first rotating gear 15, the first driving gear 16, the first reducer 17, and the first motor 18 are all arranged In th...

Embodiment 3

[0048] like Figure 5 as shown, Figure 5 It is the overall structural diagram of the antenna system of the present invention; the antenna system of the present invention includes the X-Y antenna seat and the antenna mechanism 22, and the antenna mechanism 22 is fixedly arranged on the support arm 1, and through the X-Y The control of the type antenna base realizes the directional movement of the antenna mechanism 22.

[0049] like Figure 6 as shown, Figure 6 It is a moving view of the antenna mechanism; the antenna mechanism 22 includes a central array block 23 and a pair of side array blocks 24 symmetrically arranged on the central array block 23, the central array block 23 and the The support arm 1 is fixedly connected, and the two side array blocks 24 are connected to the middle array block 23 through a turning mechanism, and the turning mechanism can realize the folding and unfolding of the antenna mechanism 22 .

[0050] like Figure 7 and Figure 8 as shown, F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com